Master Instruments available to suit High Pressure Pump P12

The following manometer types can be directly mounted onto the High Pressure

Pump P12 without adapters. For further information about these products please

refer to the specic datasheet.

General notes:

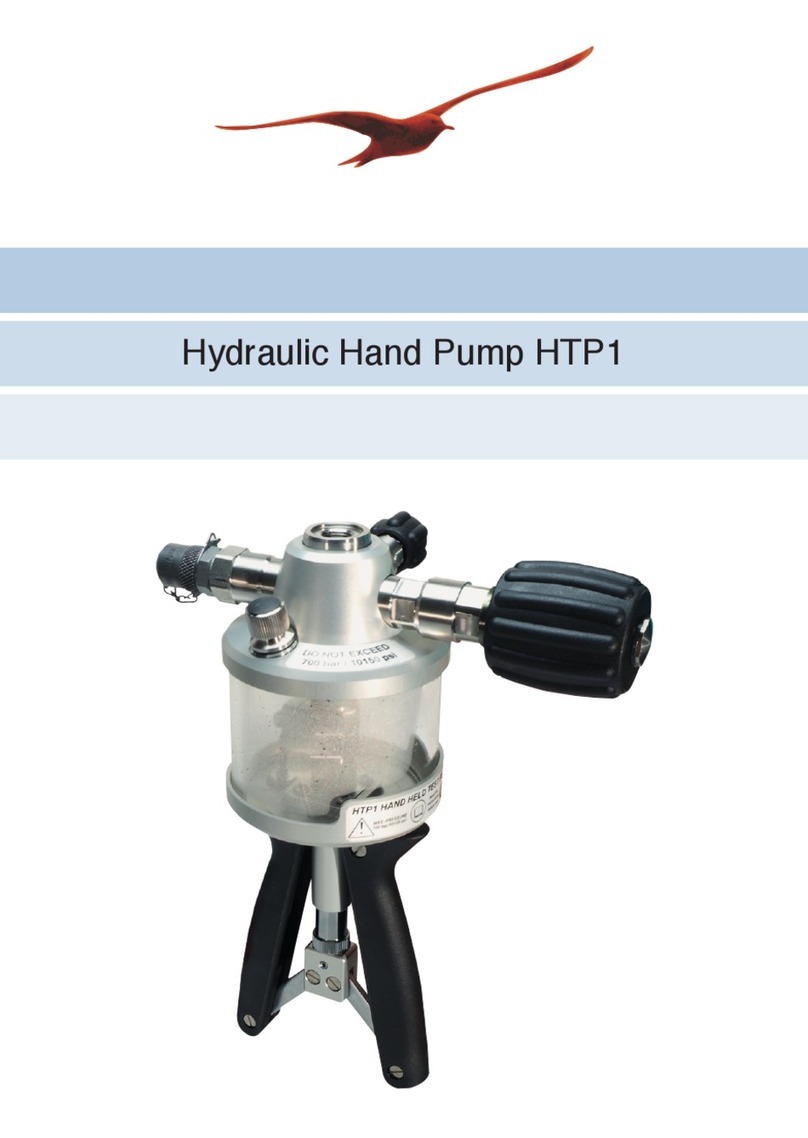

The P12 pump allows the easy generation of pressure up to 700 bar. The pres-

sure media is hydraulic oil (BP HLP 22). The oil chamber volume of 148 cm3will

pressurise large dead volumes. The pump has a ne pressure adjuster and release

valve allowing precise pressure settings, making it the ideal test equipment for mano-

meters, pressure transmitters etc.

Using the High Pressure Pump P12:

Connect the master instrument to connection (a). Tighten the instrument at the

hexagon, ensuring that the green Eolastic at seal is ush mounted.

Connect test unit to connection (e) with the high pressure quick-t connection

(supplied).

Ensure that the pressure release valve (c) is not completely closed.

Adjust the ne adjuster (b) to “mid-travel”.

Close the release valve (c) fully clockwise.

Operate lever arm (d) to generate pressure.

Adjust pressure to required value using the ne adjuster (b). Turn ne adjuster

clockwise to increase pressure and anti-clockwise to decrease pressure until the

desired pressure is reached (displayed on master instrument).

After measurements, open valve (c) slowly to release pressure.

Remove test instrument

Note: Due to thermodynamical effects in the system, the pressure may fall slightly for a

short time immediately after pressure generation. Use ne adjuster to stabilise pressure.

August 06

WARNING: To avoid possible destruction of the master- and test instru-

ments, do not exceed the max. operating pressure specied for these

instruments!

LEO 1

Accuracy: 0,2%

Intelligent Manometer

Accuracy: 0,1%

LEO 2

Accuracy: 0,1%

ECO 1

Accuracy: 0,5%

www.keller-druck.com

KELLER AG für Druckmesstechnik • St. Gallerstrasse 119 • CH-8404 Winterthur • Tel. +41 (0)52 235 25 25 • Fax +41 (0)52 235 25 00