Turning Grill Off

•Turn all knobs to OFF position.Turn LP tank off byturning

OPD handwheel clockwise to a full stop.

Ignitor Check

•Turn gas off at LP tank. Press and hold ignitor button. "Click"

should be heard and spark seen each time between collector

box or burner and electrodes. See "Troubleshooting" if no click

or spark.

Valve Check

•important: Make sure gas is off at LP tank before checking

valves. Knobs lock in OFF position. Tocheck valves, first

push in knobs and release, knobs should spring back. If knobs

do not spring back, replace valve assembly before using grill.

Turn knobs to LO position then turn back to OFF position.

Valves should turn smoothly.

General Grill Cleaning

•Keepthe outside of your grill looking new by cleaning it once a

month with warm soap and water or a non-abrasive cleaner. If

you don't havea grill cover, wipe off dust and grime before

starting your grill.

• Coating the cooking gridswith spray-on cooking oil will keep the

food from sticking and make clean up easier.After cooking,

scrape the grates with a long handled, brass wire bristle brush.

•Check inside the grill bottom for grease build upand clean

often, especially after cooking fatty meat.

•Do not mistake brown or black accumulation of grease and

smoke for paint. Apply a strong solution of detergent and water

or use a grill cleanerwith scrub brush on insides of grill lidand

bottom. Rinse and allow to completely air dry. Do not apply a

caustic grill/oven cleanerto painted surfaces.

•Plated wire grates: Wash grates with concentrated grill

cleaner or use soap and water solution. Dry thoroughly and

store indoors between cookouts.

• Plastic parts: Wash with warm soapy water and wipe dry.

,A. Do not use citrisol, abrasive cleaners, degreasers or a

concentrated grill cleaner on plastic parts. Damage to and

failure of parts can result.

•Porcelain grates: Because of glass-like composition, most

residue can be wiped away with baking soda/water solution or

specially formulated cleaner. Use non-abrasive scouring

powder for stubborn stains.

•Painted surfaces: Wash with mild detergent or nonabrasive

cleaner and warm soapy water.Wipe dry with a soft

nonabrasive cloth.

•Stainless steel surfaces: Tomaintain your grill's high quality

appearance, wash with mild detergent and warm soapy water

and wipe drywith a soft cloth after each use. Baked-ongrease

deposits may require the use of an abrasive plastic cleaning

pad. Use only in direction of brushed finish toavoid damage.

Do not use abrasive pad on areas with graphics.

• Cooking surfaces: If a bristle brush isused to cleanany of

the grill cooking surfaces, ensure no loose bristles remain on

cooking surfaces prior to grilling. It is not recommendedto

clean cooking surfaces while grill is hot.

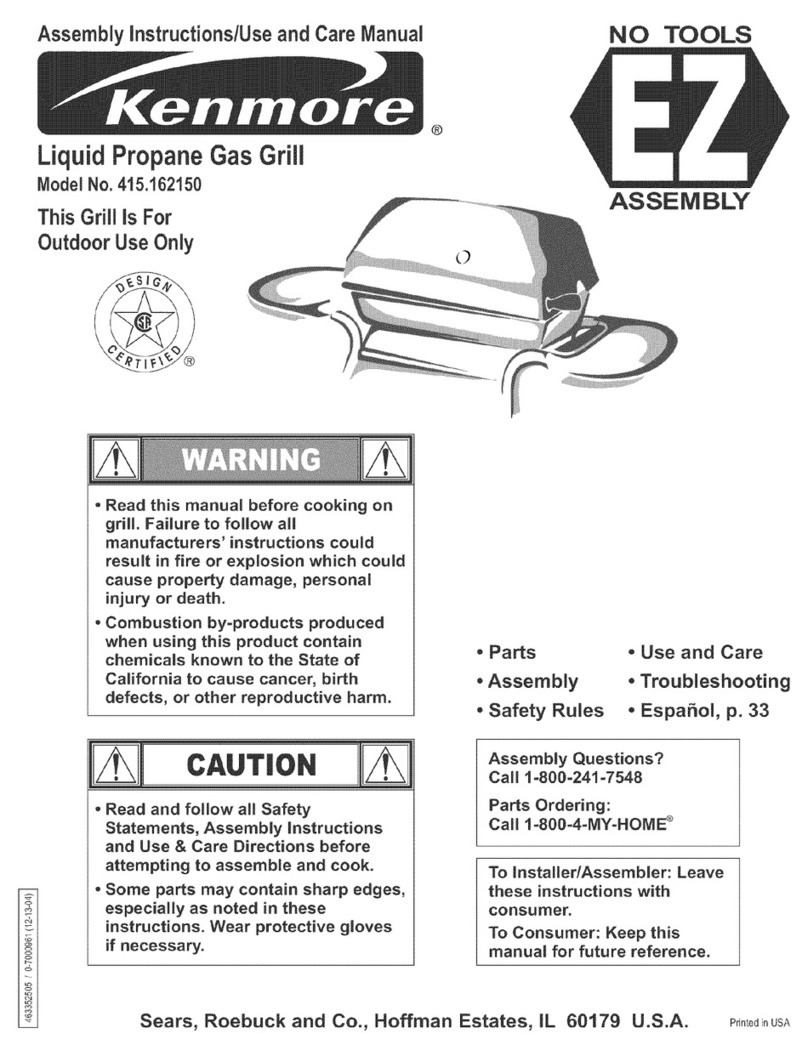

cAuT,o.

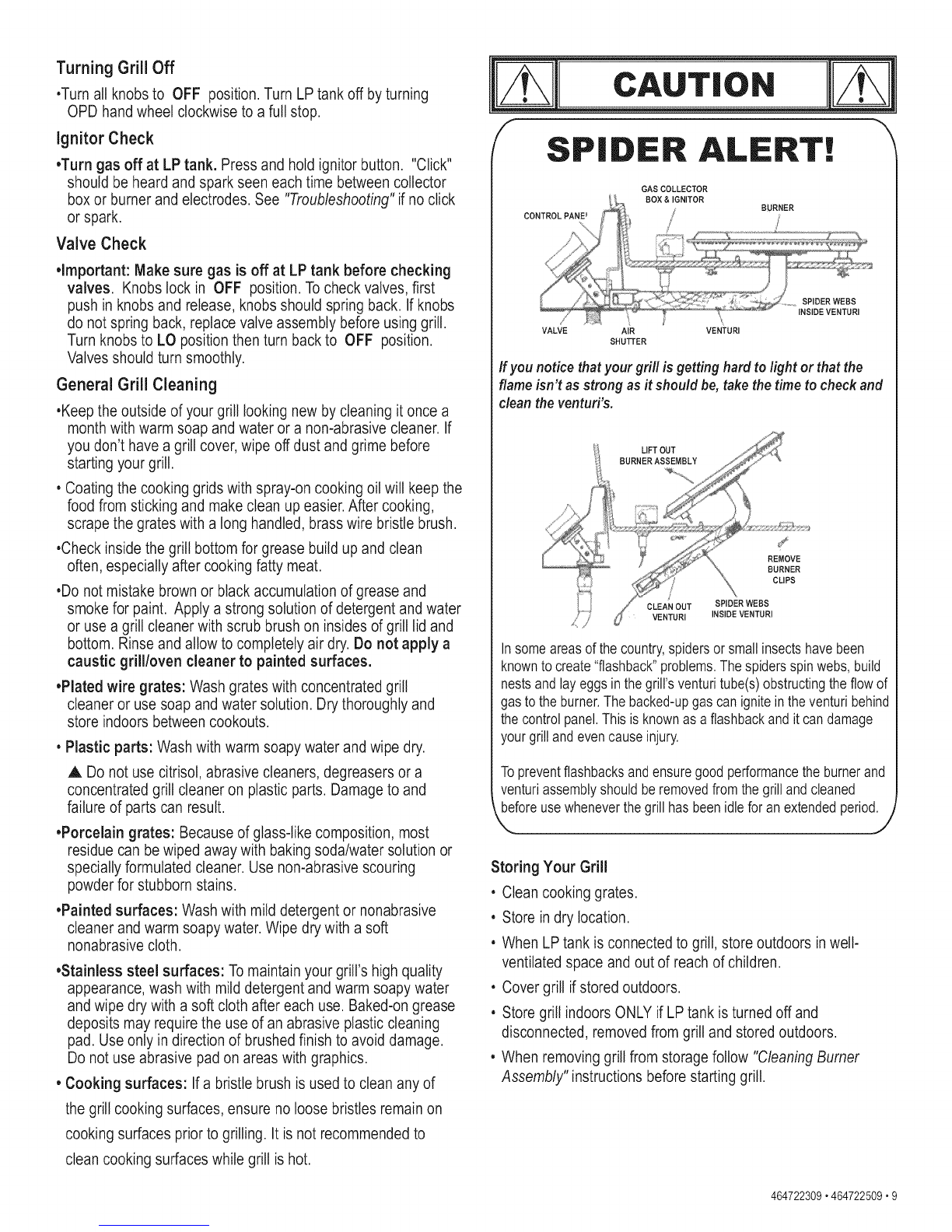

SPIDER ALERT!

GAS COLLECTOR

VALVE AIR VENTURI

SHUTTER

Ifyou notice thatyour gri// is getting hard to light or that the

flame isn't asstrong as itshou/d be,take the time to checkand

dean theventuri's.

LIFTOUT

BURNERASSEMBLY

REMOVE

BURNER

CLIPS

CLEANOUT SPIDER WEBS

VENTUR] INSIBEVENTURI

Insomeareasofthecountry,spidersor smallinsectshavebeen

knowntocreate"flashback"problems.Thespidersspinwebs,build

nestsandlayeggsin thegrill'sventuritube(s)obstructingtheflowof

gastotheburner.Thebacked-upgascanignitein theventuribehind

thecontrolpanel.Thisis knownasa flashbackanditcandamage

yourgrilland evencauseinjury.

Topreventflashbacksandensuregoodperformancetheburnerand

venturiassemblyshouldberemovedfromthegrilland cleaned

beforeusewheneverthegrillhasbeenidleforanextendedperiod.

,,. j

Storing Your Grill

• Clean cooking grates.

• Store indry location.

• When LP tank is connected to grill, store outdoors in well-

ventilated space and out of reachof children.

• Cover grill ifstored outdoors.

• Store grill indoors ONLYif LP tank is turned off and

disconnected, removed from grill and stored outdoors.

• When removing grill from storage follow "CleaningBurner

Assembly" instructions before starting grill.

464722309,464722509.9