INSTRUCTIONS FOR USE ENGLISH

Razor E17 909 6311 000(3)2009-11 1

TABLE OF CONTENTS

INTRODUCTION.............................................................................................................................................................. 2

MANUAL PURPOSE AND CONTENTS .......................................................................................................................................... 2

TARGET........................................................................................................................................................................................... 2

HOW TO KEEP THIS MANUAL....................................................................................................................................................... 2

IDENTIFICATION DATA................................................................................................................................................................... 2

OTHER REFERENCE MANUALS................................................................................................................................................... 2

SPARE PARTS AND MAINTENANCE............................................................................................................................................. 2

CHANGES AND IMPROVEMENTS ................................................................................................................................................ 2

OPERATION CAPABILITIES........................................................................................................................................................... 2

CONVENTIONS .............................................................................................................................................................................. 2

UNPACKING/DELIVERY ................................................................................................................................................. 3

SAFETY ........................................................................................................................................................................... 3

SYMBOLS ....................................................................................................................................................................................... 3

GENERAL INSTRUCTIONS............................................................................................................................................................ 3

120 VAC GROUNDING INSTRUCTIONS ....................................................................................................................................... 5

MACHINE DESCRIPTION ............................................................................................................................................... 6

MACHINE STRUCTURE ................................................................................................................................................................. 6

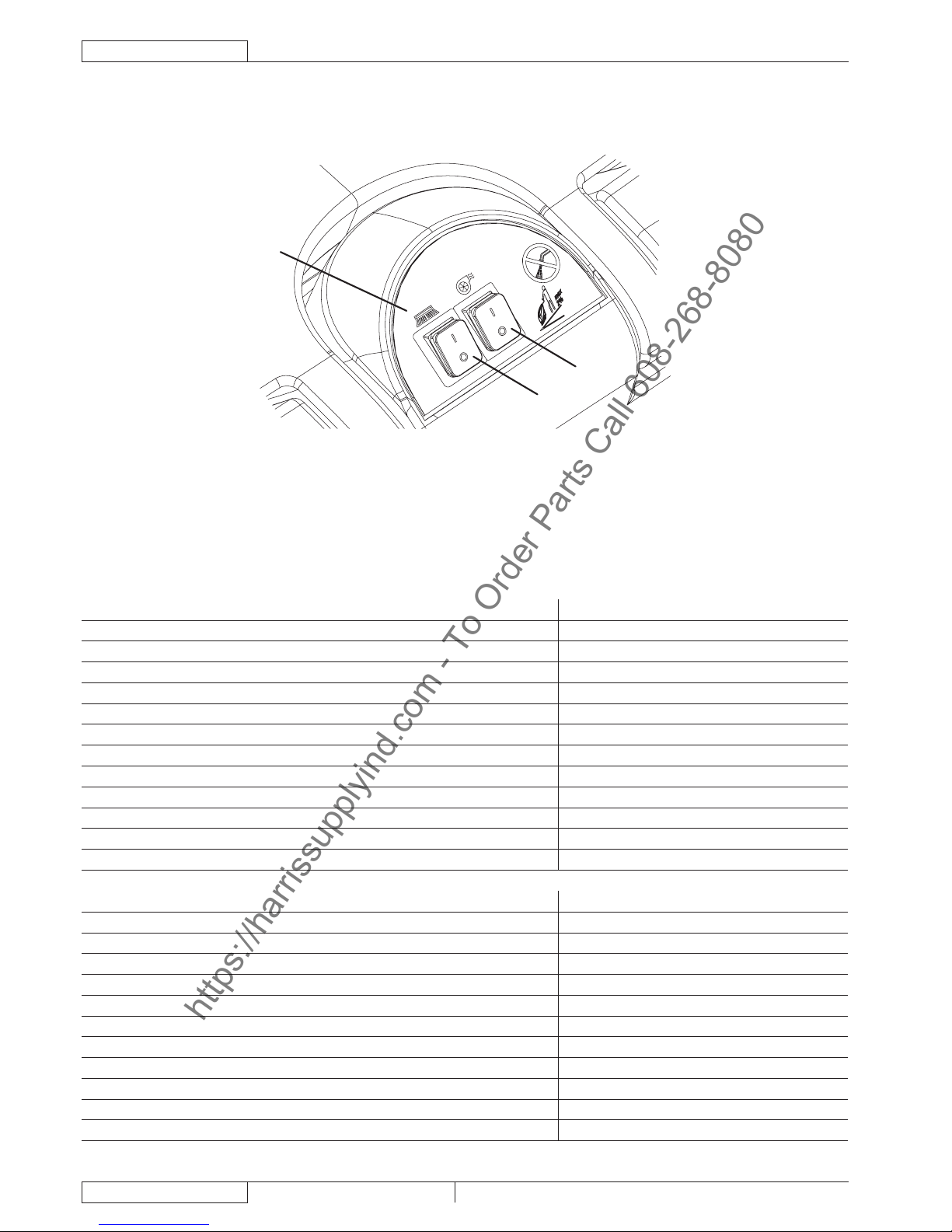

CONTROL PANEL........................................................................................................................................................................... 8

ACCESSORIES/OPTIONS.............................................................................................................................................................. 8

TECHNICAL DATA........................................................................................................................................................................... 9

WIRING DIAGRAM.......................................................................................................................................................................... 9

GROUNDING CONNECTION ......................................................................................................................................................... 9

USE ................................................................................................................................................................................ 10

BEFORE MACHINE START-UP.................................................................................................................................................... 10

MACHINE START AND STOP........................................................................................................................................................11

MACHINE OPERATION (SCRUBBING/DRYING)..........................................................................................................................11

MACHINE TRANSPORT/PARKING .............................................................................................................................................. 12

TANK EMPTYING.......................................................................................................................................................................... 12

AFTER USING THE MACHINE..................................................................................................................................................... 13

RECOVERY TANK REMOVAL ...................................................................................................................................................... 13

MACHINE LONG INACTIVITY ...................................................................................................................................................... 13

FIRST PERIOD OF USE ............................................................................................................................................................... 13

MAINTENANCE............................................................................................................................................................. 14

SCHEDULED MAINTENANCE TABLE ......................................................................................................................................... 14

INTEGRITY CHECK OF POWER SUPPLY CABLE AND EXTENSION........................................................................................ 14

SQUEEGEE CLEANING ............................................................................................................................................................... 15

SQUEEGEE BLADE CHECK AND REPLACEMENT.................................................................................................................... 15

BRUSH CLEANING....................................................................................................................................................................... 16

TANK AND VACUUM GRID CLEANING ....................................................................................................................................... 16

SOLUTION FILTER CLEANING.................................................................................................................................................... 17

MACHINE SPEED ADJUSTMENT ................................................................................................................................................ 17

TROUBLESHOOTING................................................................................................................................................... 18

SCRAPPING .................................................................................................................................................................. 18