@

ACCESSORIES

@

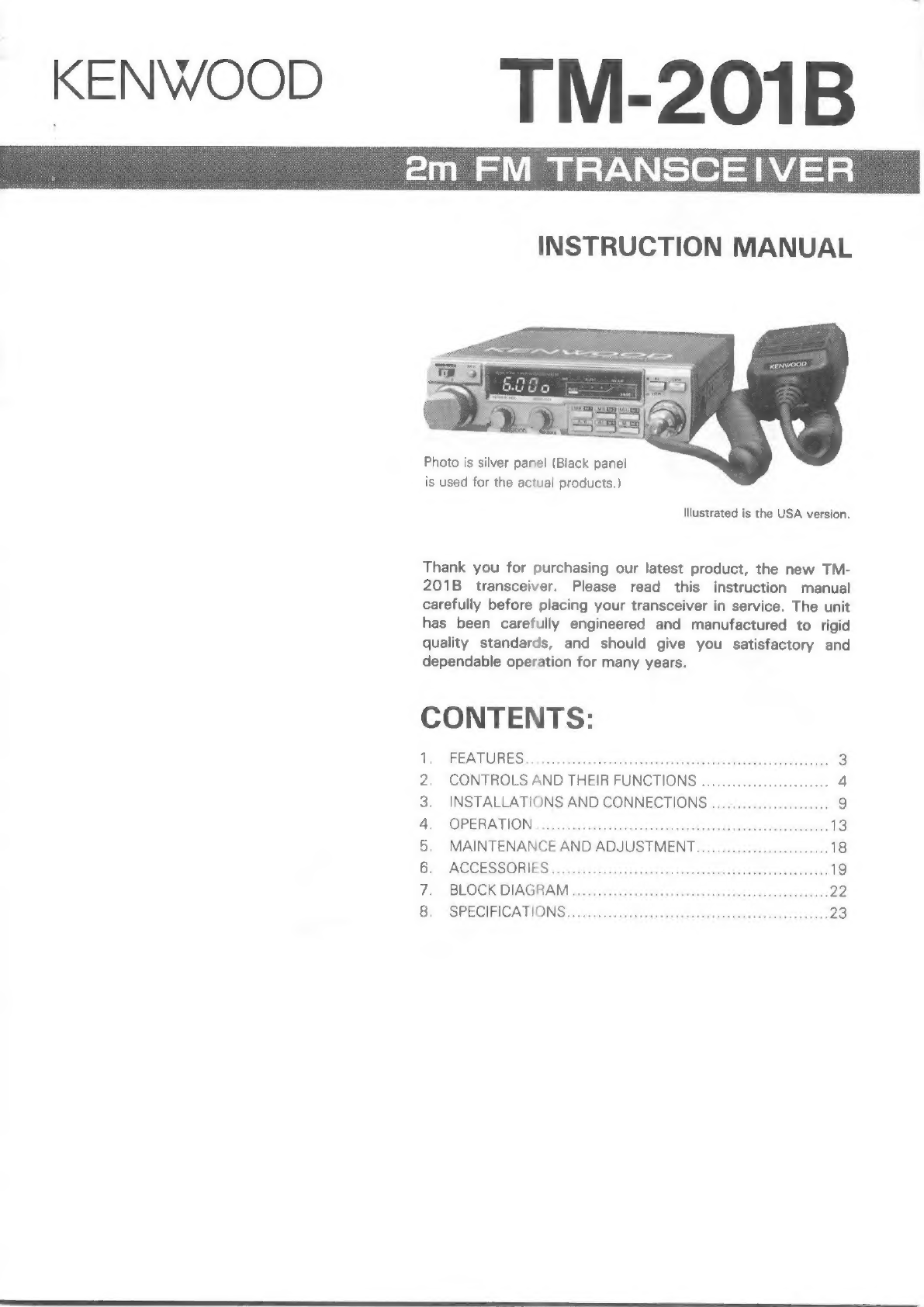

Carefully

unpack

your

TM-201B

and

confirm

that

it

is

supplied

with

the

follow-

ing

accessories:

a

@

Microphone

a

Dynamic

microphone

................0c0cccccceeeeeeseeee

(T91-0331-05)....1

pe.

b

Electret

condenser

microphone

with

touch-tone...(T91-0332-15)....1

pe.

@

Communications

speaker

(with

2.5

m

lead)

.........

(T19-0101-05)....1

pe.

@

Speaker

mounting

kit

BRBOK

GT

icsivwancoenstancnuiien

tons

sbanat

maa

oaacaamime

ei

(J21-2799-13).....1

pe.

GANG

HTTOIA

(AR)

ei

sien

vnc

wares

iva

Sahmtninas

esi

(G13-0680-04)

...1

pe.

TAPPING

SCLEW

(D4

X'S)...

nny

sane

ssacncnnaicevatewaietees

(N87-4008-41)

..4

pes.

Flat

head

tapping

screw

(#4

x

8)

.

(N88-4008-41)

..2

pcs.

Round

head

screw

($4

x

10).....

..

(N30-4010-41)

..2

pes.

For

versions

other

than

USA.

Hex.

head

nut

(4).......

ee

eT

eee

..

(N10-2040-41)

..2

pcs.

b

Mobile

mounting

kit

Mounting

bracket.........00....00.0008

(A13-0640-12)

...1

pe.

Boss

(Two

of

6

pes.

are

spare

parts.)

..

(J32-0775-14)

..6

pes.

Flat

washer

for

boss

($3)

.............

...

(N19-0631-05)

..4

pes.

Flat

screw

for

boss

(@3

x

14)

.....

...

(N32-3014-41)..4

pes.

Round

head

screw

(¢6

x

20).....

...

(NO9-0008-04)

..4

pes.

Flat

washer

(6)

...........0..00cceeeees

...

(N15-1060-46)

..4

pes

Spring

washer

(6)

......

...

(N16-0060-46)

..4

pcs.

Flange

nut

(#6)

.........

ate

..(N14-0510-04)

..4

pes.

“KENWOOD

Tapping

screw

(P5

X12)

0...

cccccencceeeneeeeeee

eee

es

(NO9-0632-05)

..4

pcs.

Flat

washer

(@5)

..........cccccscrssuceveneeeeueensneeeenes

(N15-1050-46)

..4

pcs.

For

USA:

version:

Cushion

(B)

seguas

.,..(G13-0683-04)

...1

pc.

...

(G13-0686-04)

..2

pcs.

(E30-2022-15)....1

pe.

....

(FO5-1031-05)....1

pe.

7)

[ASHUCTION

MANUAL

,..:ncrccarsrscnorensincunsomensinmnneneva

(B50-4059-00)

..1

copy

Q@@@-20053-x%--s0aGM-+0

aocm

F

hesae

ppppk

neeee

/

f

®

jA7A

PF

OP

BeE_H

Mm

eo

25

coco

4

6)

Pp

@

AFTER

UNPACKING

Shipping

container:

Save

the

boxes

and

packing

in

the

event

your

unit

needs

to

be

transported

for

remote

operation,

maintenance,

or

service.

The

following

explicit

definitions

apply

in

this

manual:

Note:

If

disregarded,

inconvenience

only,

no

risk

of

equipment

damage

or

personal

injury.

Caution:

Equipment

damage

may

occur,

but

not

personal

injury.