RA 19-4C 120318 i

TABLE OF CONTENTS

SECTION PAGE

SECTION 1 - INTRODUCTION

1.1 Scope of Manual ..................................................................................................................................... 1-1

1.2 General Description................................................................................................................................. 1-1

1.3 Electrical.................................................................................................................................................. 1-1

1.4 Mechanical.............................................................................................................................................. 1-3

1.5 Accessories............................................................................................................................................. 1-3

1.6 Options.................................................................................................................................................... 1-3

SECTION 2 - INSTALLATION

2.1 Unpacking and Inspection....................................................................................................................... 2-1

2.2 Configuring the Rack Adapter................................................................................................................. 2-1

2.3 Rack Adapter Keying Instructions ........................................................................................................... 2-1

2.3.1 Establishing Key Positions................................................................................................................. 2-2

2.4 Slot Configuration.................................................................................................................................... 2-2

2.4.1 Independent Operation...................................................................................................................... 2-3

2.4.1.1 Using one power supply to control Multiple Power Supplies ....................................................... 2-3

2.4.1.2 Sense Connections for Independent Operation (HSF 300W and 600W Modules Only) ............. 2-4

2.4.1.2.1 Independent Operation - Local Sensing Using Internal DIP switches .......................................2-5

2.4.1.2.2 Independent Operation - Local Sensing Using External Wiring.................................................2-6

2.4.1.2.3 Independent Operation - Remote Sensing ................................................................................2-7

2.4.2 Parallel Operation.............................................................................................................................. 2-8

2.4.2.1 Individual Control......................................................................................................................... 2-9

2.4.2.2 Group Control .............................................................................................................................. 2-11

2.4.2.3 Parallel, Master Selected by User, supplying balanced current to a single load ......................... 2-11

2.4.2.4 Current Balancing........................................................................................................................ 2-14

2.4.2.5 Sense Connections for Parallel Configurations (HSF 300W and 600W Modules Only).............. 2-14

2.4.2.5.1 Parallel Configuration Using DIP Switches to Connect Sense Lines in Parallel........................2-15

2.4.2.5.2 Parallel Configurations using External Wires to Connect Sense Lines

in Parallel (HSF 300W and 600W Only)..................................................................................2-17

2.4.3 Series Connection ............................................................................................................................. 2-19

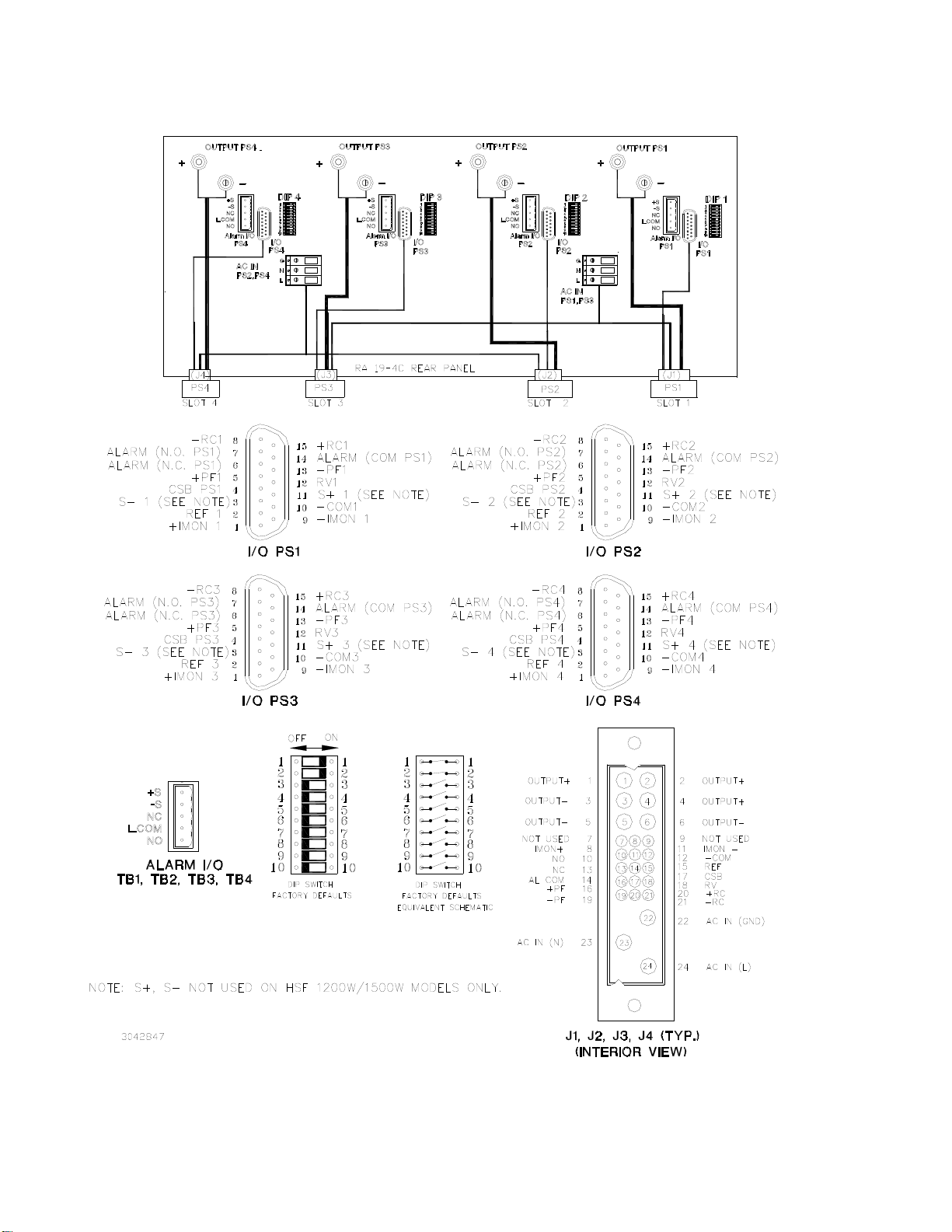

2.5 Alarm Configurations............................................................................................................................... 2-21

2.5.1 N.O. Alarm Line (Close on Failure).................................................................................................... 2-21

2.5.1.1 Close on Failure Using Rear Panel Dip Switches........................................................................ 2-21

2.5.1.2 Close on Failure Using External Wiring at I/O Mating Connector................................................ 2-24

2.5.1.3 Close on Failure Using External Wiring at Alarm I/O Terminal Block.......................................... 2-25

2.5.2 N.C. Alarm Line (Open on Failure).................................................................................................... 2-25

2.5.2.1 Open on Failure Using Rear Panel Dip Switches........................................................................ 2-26

2.5.2.2 Open on Failure Using External Wiring of I/O Mating Connector ................................................ 2-28

2.5.2.3 Open on Failure Using External Wiring of I/O Alarm Terminal Blocks......................................... 2-29

2.6 Terminations............................................................................................................................................ 2-29

2.7 Cooling.................................................................................................................................................... 2-29

2.8 Installation............................................................................................................................................... 2-30

2.8.1 Installing Optional Protective Cover................................................................................................... 2-30

2.8.2 Installing Optional Bus Bar. ............................................................................................................... 2-30

2.8.3 Installing Optional Locking Bracket.................................................................................................... 2-32

2.9 Installing HSF Power Supplies................................................................................................................ 2-33

2.10 Removing HSF Power Supplies.............................................................................................................. 2-33

2.11 Wiring Instructions................................................................................................................................... 2-33

2.11.1 Safety Grounding............................................................................................................................... 2-34

2.11.2 Source Power Connections............................................................................................................... 2-34

2.11.2.1 EMI Compliance........................................................................................................................... 2-35

2.11.3 Control Signal Connections............................................................................................................... 2-35

2.11.4 Output Load Connections.................................................................................................................. 2-35

2.11.4.1 Reducing Ripple and Noise ......................................................................................................... 2-35

2.11.4.2 Parallel/Redundant Operation...................................................................................................... 2-36