KEPCO, INC. 131-38 SANFORD AVENUE FLUSHING, NY. 11355 U.S.A. TEL (718) 461-7000 FAX (718) 767-1102

http://www.kepcopower.com email: hq@kepcopower.com

080309 228-1681 3

II — PRE-INSTALLATION.

NOTE: Either local or remote sensing MUST

be used. For independent operation

configure the DIP switches. For paral-

lel operation use external wires

DIP SWITCHES. Each slot has one DIP switch (see

Figure 3): DIP 1 is for PS1 sense lines; DIP 2 is for PS2

sense lines and for paralleling PS1 and PS2. The rest of

the DIP switches are similar to DIP 2, each configuring the

sense lines for that slot and for paralleling the adjacent

(lower number) slot. Table 1 describes the function of each

DIP switch position. See below to access the DIP switches.

ACCESSING DIP SWITCHES. The DIP switches

(Figure 3) are accessible either a) from the front without

disassembly by using a long flat-tip screwdriver after

removing all power supplies from the rack, or b) by sepa-

rating the rear panel from the chassis as described below:

1. Remove all power supplies from the rack adapter.

2. Remove eight hex spacers securing the four I/O connec-

tors to the rear panel.

3. Remove four screws (two at the top and two at the bot-

tom) securing the rear panel to the chassis and separate

the rear panel from the chassis. It is not necessary to

remove the ground connection (if present) between the

rear panel and the chassis.

4. Remove seven screws (three at the top and four at the

bottom) securing the back plate to the chassis and

remove the rear panel to gain access to the interior com-

ponents.

OPTIONAL KEYING: HSF power supplies are keyed

by voltage at the factory. A keyway can be established at

the rack adapter by installing a key pin (supplied) into the

corresponding hole as indicated in Figure 3 so that the pins

match the open holes of the power supply. Secure with

mounting nut at the rear panel using two 1/4-inch nutdriv-

ers or deep sockets. DO NOT ALTER THE KEYING ON

THE POWER SUPPLY.

INDEPENDENT OPERATION. The RA 19-(X)B rack

adapter is shipped with the DIP switches of all slots config-

ured for independent operation (see Figure 3) and local

sensing. Refer to RA 19-(X)B manual for remote sensing.

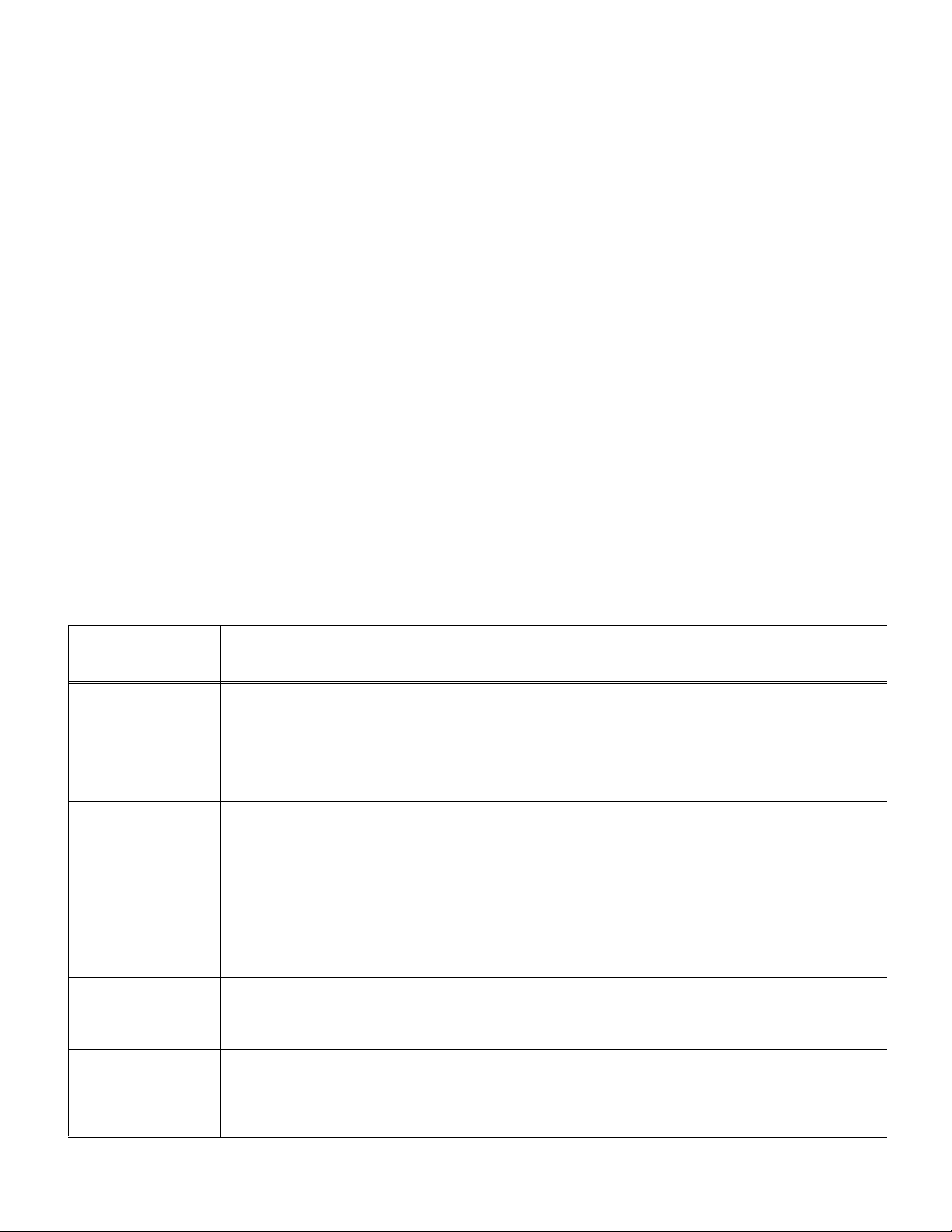

TABLE 1. REAR PANEL (INTERIOR) DIP SWITCH FUNCTIONS

DIP

SWITCH

POSITION

FUNCTION DIP SWITCH SETTINGS

1, 2

Local /

Remote

Sensing

Selection

Position 1 connects +V+ to +S, Position 2 connects –V to –S.

Both required ON (factory default) for independent operation with Local Sensing.

Both required OFF for:

a) Independent configurations using Remote Sensing.

b) Independent configurations using Local Sensing with user supplied connections from +V+ to +S and –V to –S.

c) All parallel configurations (sensing must be established using external wires).

d) All series connections.

3, 4

(SEE

NOTE)

Connect

Sense

+ and –

in parallel

Position 3 connects +S to adjacent slot +S, Position 4 connects –S to adjacent slot –S.

Both required OFF (factory default) for all configurations except parallel configurations using DIP switch settings to con-

nect the sense leads in parallel.

Both required ON for parallel configurations using DIP switch settings to connect the sense leads in parallel.

5

Current

Balance

(forced

current

share)

Required ON for parallel operation with forced current share (connects current share lines in parallel) unless connec-

tions are made via external wires

Required OFF (factory default) for

a) independent and series configurations.

b) Parallel configurations using external wires at I/O connector to connect CSB (current share bus) lines in parallel.

c) Parallel configurations without forced current sharing (current balancing),

6, 7

Close on

Failure

Alarm

When set to OFF (factory default), individual power supplies produce closure between I/O connector N.O. and COM

pins upon failure.

When set to ON, parallels N.O pins of adjacent slots to allow a single alarm to provide failure indication (contact closure

between N.O. pin and COM pin) if any one of many power supplies fails.

8

Open on

Failure

Alarm

When set to OFF (factory default), individual power supplies produce open between I/O connector N.C. and COM pins

upon failure.

When set to ON, connects N.C to COM between adjacent slots so that individual alarms are connected in series. This

allows a single alarm to provide failure indication (contact open between N.C. pin and COM pin) if any one of many

power supplies fails.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com