KEPCO, INC. 131-38 SANFORD AVENUE FLUSHING, NY. 11355 U.S.A. TEL (718) 461-7000FAX (718) 767-1102

http://www.kepcopower.com email: hq@kepcopower.com

110122 228-1671 REV 2 3

Configure DIP 3:

1. Set positions 1 and 2, to ON. This connects +S to +V

and –S to –V for slot 3, establishing local sensing for slot

3.

2. Set positions 3 and 4, to OFF. This isolates sense lines

(±S) between slots 3 and 2.

3. Set position 5 to OFF. This isolates the current share

bus (CB) between slots 3 and 2.

4. Set position 6 and 7, to OFF. This isolates the ALARM

(N.O.) and ALARM (COM) lines between slots 3 and 2.

5. Set position 8 to OFF. This position is only set to ON for

open-on-fail alarm circuits.

6. Set position 9 to OFF. Isolates RV (remote voltage) lines

between slot 3 and 2, however RV is not used (output

voltage is controlled by the front panel trimpot).

7. Set position 10 to OFF. This isolates common (-COM)

lines between slots 3 and 2.

SERIES OPERATION. See Operator Manual for

series operation details.

ALARMS. For independent configurations, Close on

Fail contact closure is across I/O connector pins 7 (ALARM

N.O.) and 14 (ALARM COM). Open on Fail circuits are

across I/O connector pins 6 (ALARM N.C.) and 14 (ALARM

COM). Figure 3 shows a parallel close-on-fail circuit for

slots 3 and 4 using the DIP switches to make the connec-

tions. See Operator Manual for other options.

III — INSTALLATION

MOUNTING RACK ADAPTER: The rack adapter

mounts directly to EIA-RS 310D standard 19" racks via the

two mounting ears; two screws are required per mounting

ear for proper support. CAUTION: RACK ADAPTER

SHOULD BE MOUNTED BEFORE INSTALLING POWER

SUPPLIES. Install each HSF power supply in desired slot

and secure using two retaining latches as described by the

applicable HSF Power supply manual. Make sure the two

latches are in the open position before installing HSF mod-

ules.

The rack adapter is supplied with six cable clamps

equipped with release levers that can be snapped into

holes provided in the rear panel (see Figure 1) to support

the weight of the input, output and signal cables.

OPTIONAL PROTECTIVE COVER: A clear plastic

cover (Kepco P/N 137-0145) is available as an accessory

to protect the rear terminals against accidental contact.

See Operator Manual for details.

OPTIONAL BUS BAR: Bus bars which connect output

terminals for parallel or series operation are available as

accessories. See Operator Manual for details.

OPTIONAL KEYING: HSF power supplies are keyed

by voltage at the factory. The keyway is established by

installing screws (4-40 x 0.75 in. thread-forming, Kepco P/

N 101-0480, provided) into the corresponding holes as

indicated in Figure 2 so that the only holes open match the

power supply pins. DO NOT OVERTIGHTEN these screws

(max torque 5 in.-lbs. (0.6 N x m). User-modified keying

can differentiate between modules with same keyways

(e.g., 36V and 48V) or between identical HSF models but

with different adjustments; see Operator Manual for

details.

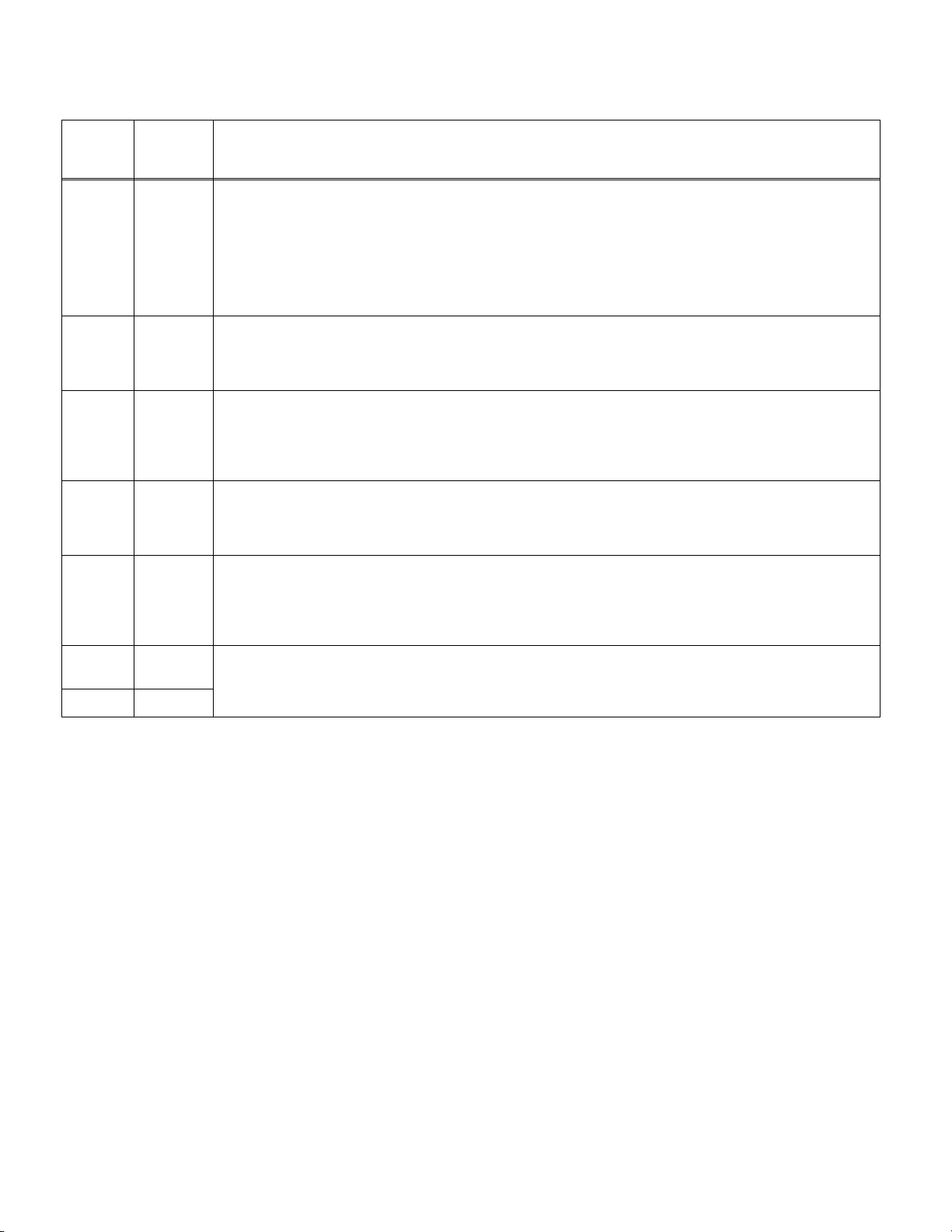

FIGURE 2. RACK ADAPTER KEYING

OPTIONAL I/O CONNECTOR: Mating Europlugs

(Kepco P/N 142-0544) for the Alarm I/O Euroheaders are

available as accessories for the Sense connections (±S)

and independent Alarm connections.

OPTIONAL A-C CONNECTIONS: Two line cords are

available as accessories. In North America where 115/

230V a-c source power is used, Kepco recommends the

use of a Kepco line cord (P/N 118-1145, North American

style plug, 30A maximum, 6 ft. long). European applica-

tions may require the use of Kepco line cord P/N 118-1146

(250V, 32A maximum).

INSTALLATION/REMOVAL OF HSF POWER SUP-

PLIES: Use two retaining latches on each HSF power

supply to install or remove power supply to/from desired

slot in accordance with the applicable HSF Power supply

manual. Refer to RA 19-4C Operator Manual for keeping

= SCREW TO BE INSTALLED

AT REAR PANEL.

= NO SCREW INSTALLED.

DESIRED VOLTAGE 5V 12V15V 24V 28V 36V 48V