7

14

8

9

10

12

13

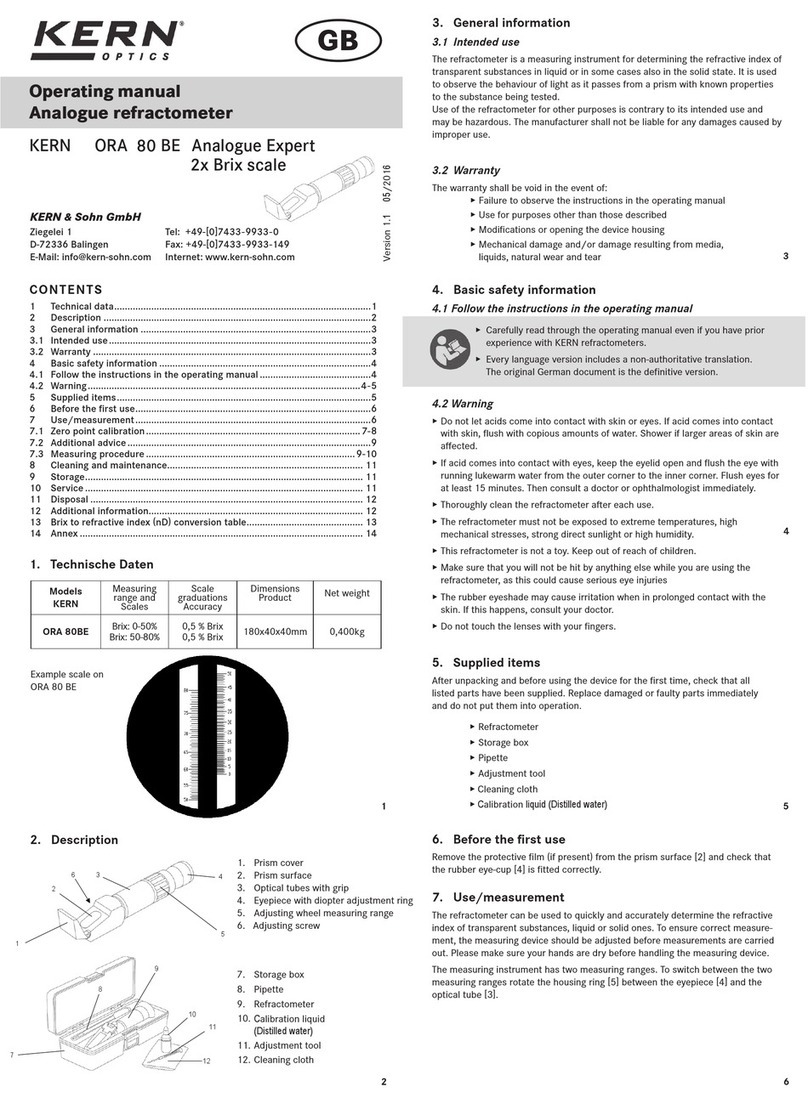

7.1 Zero point calibration

▸ Hold up the refractometer against a sufficiently bright light source and look through

the eyepiece [5], holding the rubber eyeshade [4]closely against your eye/glasses.

▸ Rotate the eyepiece [5]to adjust it for your eyesight, until you can see the scale

sharply.

▸ Open the prism cover [1].

▸ Thoroughly clean the prism [2]and the underside of the prism cover [1]using a so

cloth or soft paper (with alcohol if necessary)and wipe dry.

▸ Now apply a few drops of the calibration liquid [10]onto the prism surface [2].

▸ Close the prism cover [1]. The amount of fluid should be sufficient to moisten most

of the prism surface. There should not be any air bubbles between the measuring

prism [2]and prism cover [1].

▸ Wait about 30 seconds to allow the temperatures of the fluid and prism to

equalise.

▸ Look through the eyepiece [4]while pointing the refractometer‘s prism surface [2]

at a bright light source.

▸ Through the eyepiece [4], you will see a bright and a blue field. The boundary line

between them shows the measured value on the scale which is also visible

through the eyepiece [4].

▸ Use the supplied adjustment tool [11]to turn the adjustment screw [3]behind

the prism surface [2](under the rubber cap), and adjust the scale so that the

measuring device is optimally set up by moving the boundary line upwards or downwards.

Calibration value ORA 4FA/4FB: 0 °C EG / PG / CW

▸ Repeat step 4 (cleaning).

Important!

The ambient/room temperature and the sample temperature influ-ence

the refractometer measuring result. The scales of the refractometer

models, which have "FB" in its name, are designed for an ambient

7.2 Additional advice

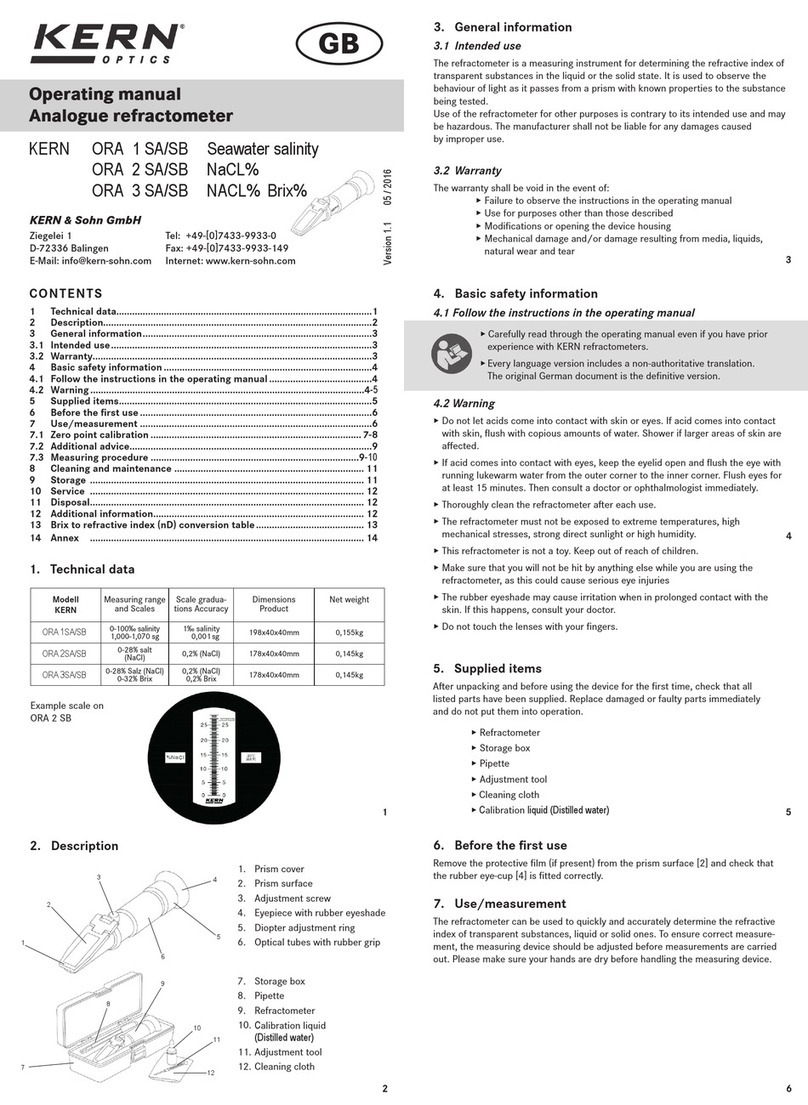

It is important that the samples being measured are representative samples. For

samples that evaporate easily, measurements should be carried out quickly. The

samples should be at the same temperature as the measuring instrument in order

to achieve an accurate result.

9

11 ORA_1SB_2SB_3SB-BA-e-1510

13 Brix to refractive index (nD) conversion table

Data from "ICUMSA" International Commission for Uniform Methods

of Sugar Analysis, at 20 °C and 589 nm wavelength.

8. Cleaning and maintenance

Clean the refractometer using a so, lint-free cloth moistened with either water

or, if necessary, alcohol. Do not use any aggressive or abrasive cleaning agents.

Never immerse the device in water or hold it under running water. Never handle the

device with wet or damp hands.

Never touch the measuring prism [2]with hard tools made from plastic, wood,

rubber, metal, glass etc. Hard objects can quickly damage the relatively so prism

glass, resulting in measurement errors.

The refractometer is maintenance-free.

Cleaning should be carried out immediately before and aer each use of the refrac-

tometer to maximise its life and optimise measurement results.

9. Storage

Store the refractometer in a dry, non-corrosive environment, preferably

between 10 °C and 30 °C.

10. Service

Aer reading this operating manual, if you have any questions about setting up

or using the refractometer, or if any unexpected problem occurs, please contact

your dealer. The device housing may only be opened by trained service technicians

authorised by KERN.

11. Disposal

The packaging consists of environmentally friendly materials which can be disposed

of via local recycling facilities.

The device and storage box should be disposed of by the operator in accordance

with applicable national or regional regulations at the place of use.

12. Additional information

The product may differ slightly from the illustrations. Avoid exposing the refracto-

meter to direct sunlight. Never bring the refractometer into contact with solvents.

!

ORA_1SB_2SB_3SB-BA-e-1510

Table 1: International Temperature Correction Table for°Brix (% sugargradient)

temperature of +20 °C! If the measurements are carried out at a temperature other than +20 °C,

the results must be correspondingly corrected.

Refractometer models, which have "FA" in its name, are equipped with an automatic

temperature compensation (ATC). Between +10°C and +30°C measurement differences due to

temperature changes are automatically compensated.

7.3 Measuring procedure for antifreeze testing

▸ Open the prism cover [1]and use the supplied pipette [8]to apply a few drops of

the sample coolant [8]onto the prism surface [2], then close the prism cover [1].

Spread the liquid evenly by pressing down on the prism cover [1]and eliminate any

air bubbles present.

▸ Close the prism cover [1]and view the measurement scale through the eyepiece

[4]. Point the prism surface [2]of the refractometer at a bright light source while

doing this.

▸ Rotate the adjustment ring [5]on the eyepiece [4]to adjust the focus.

▸ The boundary line will move on the measurement scale depending on the anti-

freeze concentration. This light/dark boundary on the antifreeze scale [B]directly

indicates the freezing point of the antifreeze mixture in °C. The figures show the

measured value for propylene* (G13) and the measured value for ethylene**

(G11/G12). If the antifreeze used in not known or it is a mixture of both, the

propylene scale must always be used. Only then can sufficient coolant antifreeze

protection be reliably guaranteed.

▸ The measurement result is not influenced by the temperature of the coolant.

▸ Carefully clean the supplied pipette [8]and the refractometer aer carrying out the

measurement.

7.4 Measuring procedure for windscreen wiper water testing

▸ The measuring procedure is identical to that for antifreeze testing.

▸ The measured value can be read off the windscreen wiper water testing scale [C]in

°C and provides a guide value, because the composition of the individual antifreeze

agent varies.

▸ Carefully clean the supplied pipette [8]and the refractometer aer carrying out the

measurement.

!

7.5 Measuring procedure for determining battery acid density

▸ Instead of antifreeze solution, place some battery acid on the prism surface [2]

using the pipette [10].

▸ Using the light/dark boundary on the measuring scale for determining battery

acid density [A]„- / +“, read off the acid density in g/cm³ (kg/l).

▸ The scale [A]is divided into three regions for determining the charge condition.

RECHARGE = replace/recharge (<1.20 g/cm³);

Charge ~50%

FAIR = acceptable (1.20 to 1.25 g/cm³);

Charge ~75%

GOOD = good (>1.25 g/cm³);

Charge ~100%

* Propylenes are preferentially used as antifreezes in the European region.

** Ethylenes are preferentially used as antifreezes outside of the European region.

Important!

Aer every measurement, use a lint-free, absorbent cloth to remo-

ve the fluids from the prism surface [2]and prism cover [1]. Then

carefully clean the prism and prism cover using a cloth moistened

with water or if necessary alcohol, and dry both parts using a so,

dry and lint-free cloth. Avoid rubbing the prism [2].

11