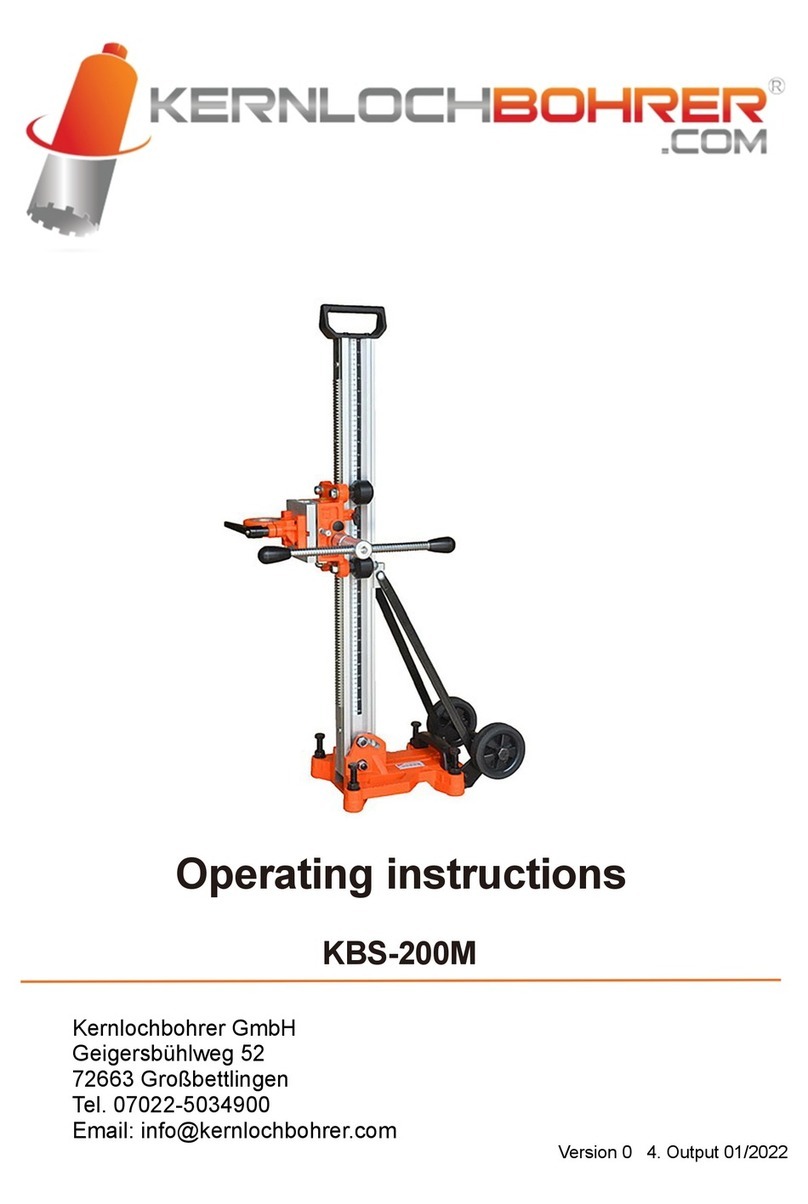

Check if the guide on the column is loose. If it is loose, you must adjust the 4

eccentric clamps inside the drill carriage. Use a 13mm wrench and an 8mm

wrench to tighten the clamping nut for adjustment. Now test the proper fit of the

drill slide by cranking it up and down. There should be no play, but also no

jamming throughout the travel.

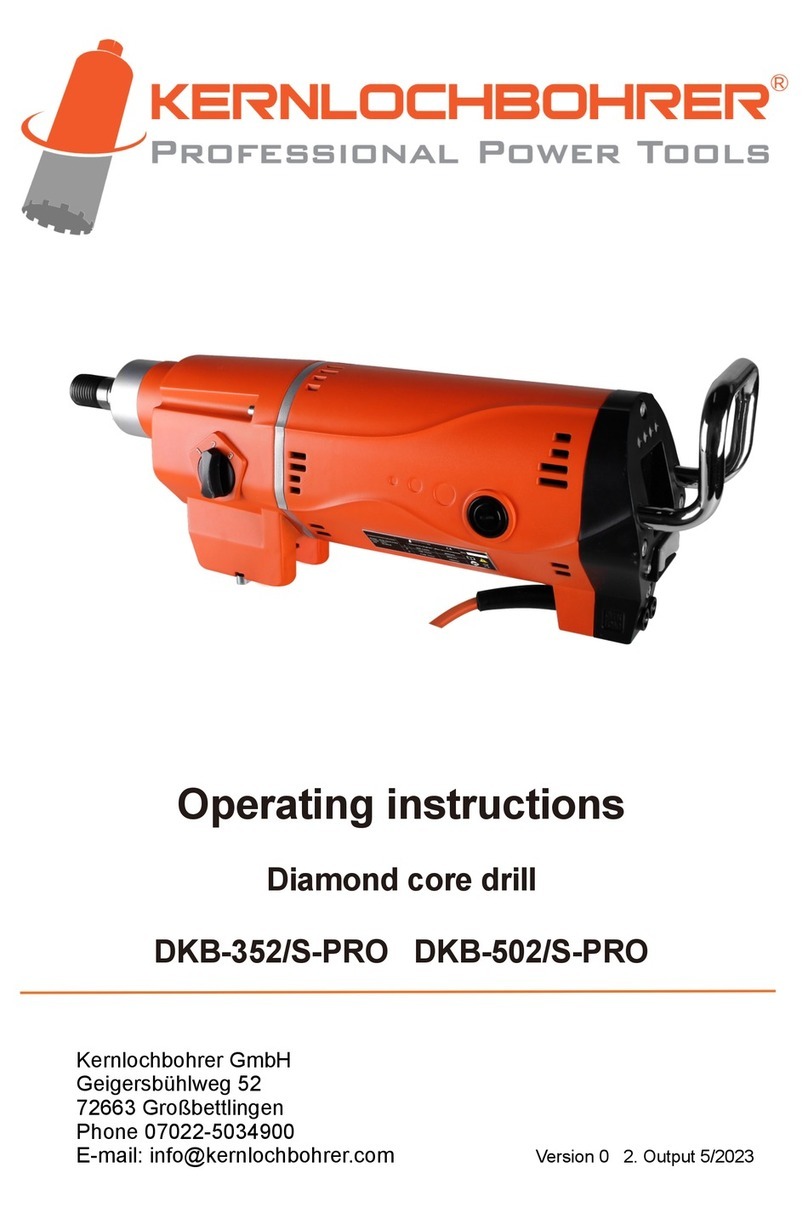

The KBS-352/M-PRO/KBS-352/XL-PRO and KBS-502/

M-PRO each have a different mounting adapter. The

mounting adapter of the KBS-352/M-PRO and KBS-352/

XL-PRO is 60mm while the mounting adapter for the

KBS-502/M-PRO is 110mm to allow drilling with larger

diameter drills.

Before mounting the drill motor

on the stand, first set the drill

slide to a higher position to

make it easier to mount the

adapter plate.

When mounting a drill rig of the DKB-PRO series to the core drill rig KBS-352/M-

PRO, KBS-502/M-PRO, KBS-352/XL-PRO, you first need 4 screws to fix the

mounting adapter to the motor. There is a 10x10x100mm keyway on the

mounting adapter, which absorbs the torque of the motor via the key. Now adjust

the locking screw so that the fastening adapter can be inserted effortlessly. Now

place the fastening adapter with the dovetail in the guide. Tighten the locking

screw until the plate is secured in the guide. To be able to remove the drill motor

again, loosen the fastening screw completely.