THESE INSTRUCTIONS MUST BE READ AND ADHERED TO

BEFORE OPERATING THIS MACHINE.

SAFETY MANAGEMENT PROCEDURES

Failure to comply with safety recommendations may result in injury to the operator, nearby

persons, or damage to property, or this machine.

Always transport your machine in an upright and horizontal position.

This machine can cause severe injury if the water jet is pointed at any party of the body,

so keep hands, feet, other body parts and animals out of the pressure jet.

ALWAYS wear protective goggles and suitable protective clothing when this operating

appliance. Non-slip rubber footwear must be worn when operating this machine.

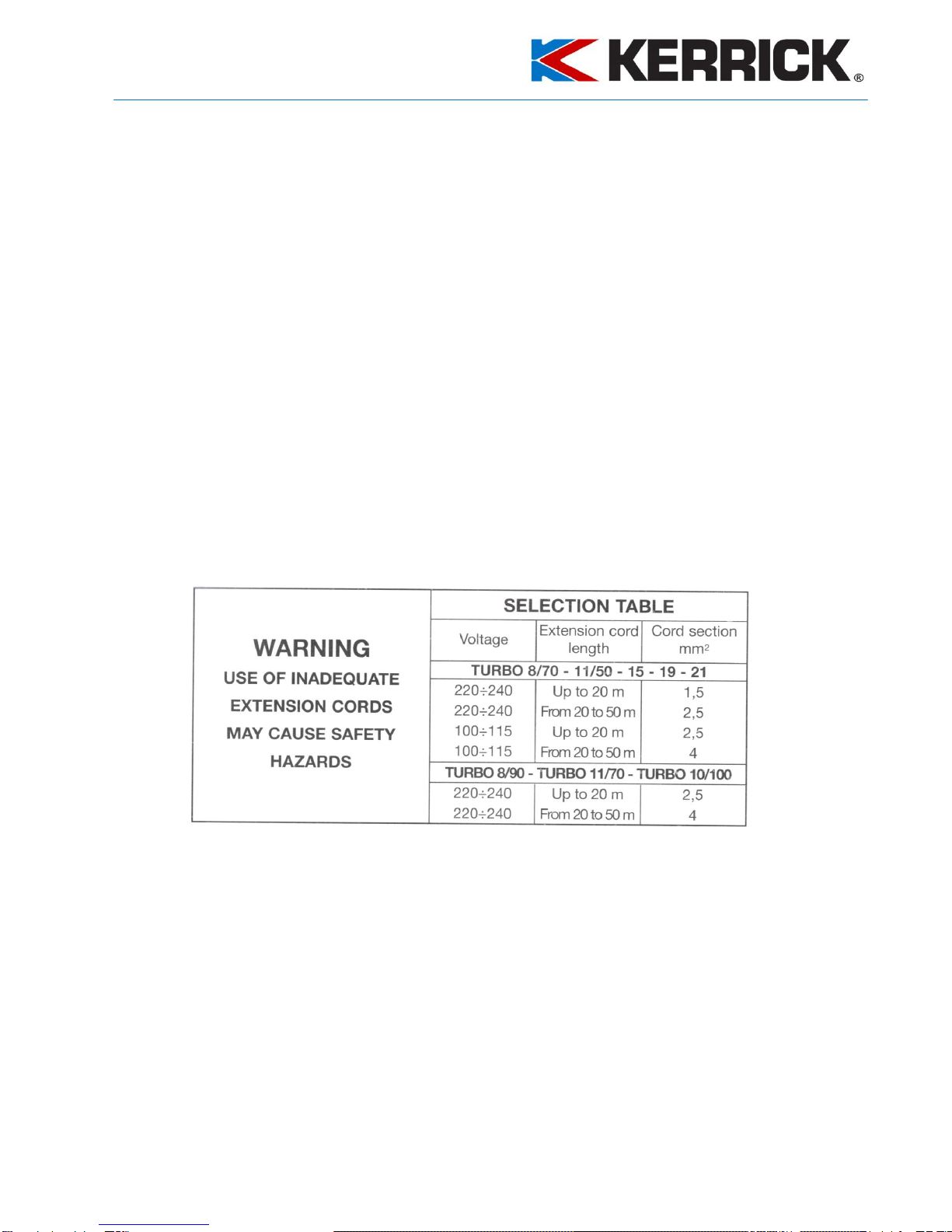

NEVER let the electric motor switch or electrical cord get wet. USE AN EARTH

LEAKAGE DEVICE.

Do not touch the appliance with wet/damp hands or feet and do not use the appliance bare-

footed or with unsuitable clothing.

Do not pull the supply cable or the appliance itself in order to disconnect the plug from the

electric supply.

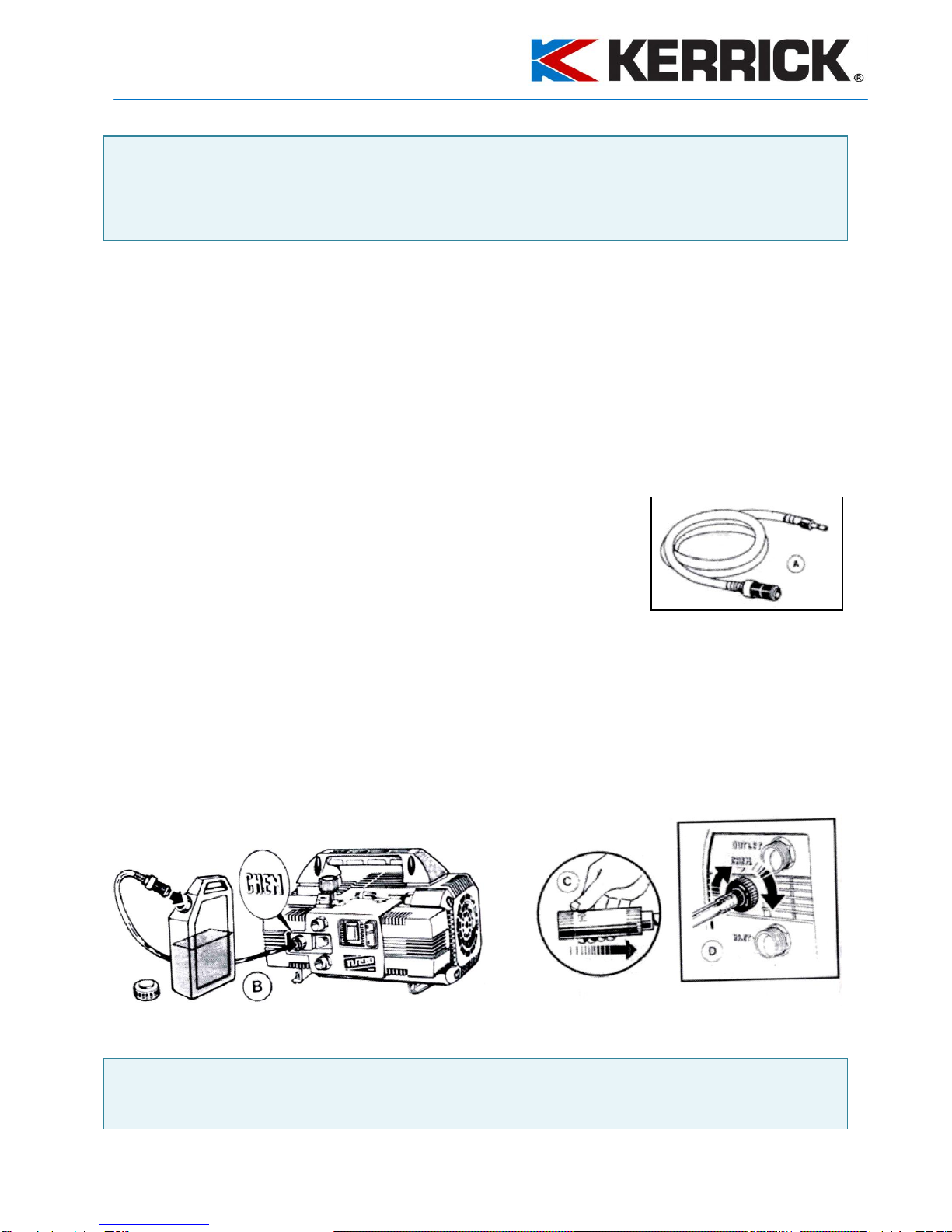

NEVER run the machine without water in the pump.

Check engine and pump oil daily.

Check that water connections are tight and that there are no leaks from the machine.

DO NOT work the machine for more than 1 to 2 minutes with gun in CLOSED position.

After switching machine 'OFF' point lance in a safe direction and press trigger on gun

handle to release any built-up pressure before moving or working on this unit.

Protect machine from weather. DO NOT leave out in rain or freezing conditions. DO

NOT use if water pipes have frozen or if temperatures fall below zero, without taking

special precautions.

In case of damage or malfunction, switch off the appliance and disconnect it from the mains

electricity by removing the plug, then call an authorised service person.

DO NOT attempt to fix or repair the unit. All adjustments or overhauls should be carried

out by a Kerrick authorized service agent only.

Use only Kerrick accessories which are designed to operate with your machine.