Kersten KM 50 Series User manual

Order number: B00061 from machine number: Rev.: R00 Date: 27.10.2014

The original operating instructions

Front Sweeper

KM 50

KM 13050 M-ABR 50 / KM 13050 H-ABR 50

KM 14750 M-ABR 50 / KM 14750 H-ABR 50

KM 16550 M-ABR 50 / KM 16550 H-ABR 50

KM 19050 M-ABR 50 / KM 19050 H-ABR 50

KM 22550 M-ABR 50 / KM 22550 H-ABR 50

Roll diameter 50 cm

for municipal tractors u. Carrier vehicles from 18 kW

Manufactures by

Kersten Arealmaschinen GmbH

Empeler Straße 95

D - 46459 Rees

www.kersten-maschinen.de

Distributed in UK by

Kersten (UK) Ltd Tel. 0118 986 9253

Progrees House 39 Boulton Road

Reading, RG2 0NH

www.kerstenuk.com - [email protected]

Table of Contents

2

1

Letter ...................................................................................................................... 3

2

About this manual................................................................................................. 4

2.1

BEFORE COMMISSIONING................................................................................................................................. 4

NOTES ABOUT THIS MANUAL....................................................................................................................................... 4

3

Safety instructions for implements ..................................................................... 5

3.1

INTENDED USE......................................................................................................................................................... 5

3.2

GENERAL SAFETY AND ACCIDENT PREVENTION RULES............................................................... 5

4

Disposal .............................................................. errors! Bookmark not defined.

5

Guarantee ............................................................ errors! Bookmark not defined.

6

Recommendations .............................................. errors! Bookmark not defined.

6.1

LUBRICANTS ......................................................................................ERRORS! TEXT MARK NOT DEFINED.

6.2

MAINTENANCE AND REPAIR FAULT.....................................ERRORS! TEXT MARK NOT DEFINED.

7

MOUNTING........................................................................................................... 10

7.1 INSTALLING KM 13050-22550 M-ABR 50 AND KM 13050- 22550H-ABR 50......................... 10

7.2 INSTALLING A KM 13050- KM 22550 M-ABR 50..................................................................... 10

7.3 INSTALLING A KM 13050-22550 H-ABR 50............................................................................. 12

7.4

MOUNTING DIRT MATERIAL CONTAINER................................................................................................ 12

7.5

MOUNTING SIDEBOOK...................................................................................................................................... 12

7.6

MOUNTING THE WATER PRESSING DEVICE......................................................................................... 14

8

Operation ............................................................................................................. 15

8.1

OPERATING INSTRUCTIONS - SWEEPING MACHINE........................................................................ 15

8.2

DIRT COLLECTION SETTING.......................................................................................................................... 15

8.3

SIDEBOOK SETTING........................................................................................................................................... 15

9

Maintenance ........................................................................................................ 16

9.1

GENERAL.................................................................................................................................................................. 16

9.2

MAINTENANCE....................................................................................................................................................... 16

9.3

DAILY TESTING...................................................................................................................................................... 16

9.4

MAINTENANCE AFTER 20 BZW. 100 HOURS OF OPERATION OR LONGER SERVICE TIME............ 16

9.5

INSTALLATION OF THE ROLLING GEAR................................................................................................... 16

10

TECHNICAL DATA .............................................................................................. 17

10.1

KEHR MACHINE ................................................................................................................................................ 17

10.2

DELIVERY SERIAL ........................................................................................................................................... 17

10.3

OPTIONAL EQUIPMENT................................................................................................................................ 17

11

EC Declaration of Conformity ............................................................................ 18

Introduction

3

1 Introduction

Dear Customer,

Thank you for choosing a quality product from Kersten.

This product has been manufactured according to the most up-to-date production methods and extensive

quality assurance measures, because only when you are satisfied with your device, our goal is reached.

Before using this machine or implement for the first time, please read this manual thoroughly and thoroughly.

If you do not understand any of the information contained in this safety data sheet or the product-specific

installation or operating instructions, please contact your sales representative or the machine manufacturer

directly.

Keep this manual handy. If necessary, you can read important information and instructions.

Have fun with your Kersten - device wishes you

Dipl.- Ing. (FH) Robert Bosch

Managing Director

About this manual

4

2 About this manual

The machine or attachment is subject to technical progress. All information, illustrations and

technical data are up-to-date at the time of publication. Changes in the sense of technical

progress are reserved to the manufacturer at any time.

2.1

Before commissioning

As self-propelled implements and attachments can cause serious accidents or hazards if used

improperly, a briefing of competent and authorized persons is mandatory when commissioning

the Kersten implement for the first time. The best way to familiarize yourself with its basic

functions and its handling is to choose a free and level terrain for your first trip.

•

You reduce the risk of accidents on your part or third parties!

For further information and difficulties of any kind, please contact the dealer, importer or

directly to the manufacturer.

•

Be sure to read the safety instructions on the following pages!

•

Read the operating instructions before commissioning!

•

Pass on all safety instructions to other users!

Notes on this manual

Enumerations are marked with eye-catching points.

Example:

•

Text

•

Text

Instructions are marked according to the order in which they are to be carried out.

Example:

1.

Text

2.

Text

Safety

5

3 Safety instructions for implements

The most important safety instructions in this manual can not cover all possibilities. It goes without

saying that common sense and caution are factors that are not built into a machine, but must be

brought by the person who uses and maintains the machine.

In order to keep the accident risk as low as possible, please observe the following

subchapters.

3.1

Intended use

•

The sweeper has been developed for sweeping on paved surfaces, sidewalks and facilities for

the usual or common use in the area of area care.

•

Any other use is considered improper use. The manufacturer is not liable for any damage

resulting therefrom, the risk being solely borne by the operator.

•

Proper use also includes compliance with the operating, maintenance and service conditions

specified by the manufacturer.

•

The attachment may only be used, maintained and repaired by persons who are familiar with it

and have been informed of the dangers.

•

The relevant accident prevention regulations as well as the other generally accepted safety

and occupational medical rules must be observed.

•

Unauthorized modifications to the machine lead to the exclusion of liability of the manufacturer

for the resulting damage.

3.2

General safety and accident prevention regulations

3.2.1

Basic rules

•

In addition to the instructions in this operating manual, observe the general valid safety and accident

prevention regulations!

•

The implement must not be operated by persons under the age of 16, not even under the

supervision of an adult! Children and adolescents should be instructed not to play with it.

•

Only trained personnel or persons may use this machine!

•

When using public traffic routes, observe the relevant regulations!

•

The user's clothing should fit snugly. Avoid loose-fitting clothing and wear sturdy shoes or safety

shoes!

•

Only work in good visibility and light conditions!

•

The attached warning and information signs provide important information for safe operation; the

attention serves your safety!

•

Beware of oscillating brushes - keep safety distance!

•

Be careful with trailing machine parts. Wait for work on them until they are completely stopped!

•

There are crushing and shearing points on driven parts!

•

Driving behavior, steering and, if applicable, braking capability and tilting behavior are influenced by

mounted or attached implements and load. For this reason, only implements approved by the

manufacturer may be used. The working speed must be adapted to the respective conditions.

•

Unauthorized conversions that endanger the operational safety of the machine are prohibited!

•

Check the machine for operational safety before each use!

•

Never remove or change protective devices!

•

Never go under the unsecured device for repair or inspection!

Safety

6

3.2.2

Work and danger area

•

The user is responsible to third parties in the work area!

•

Staying in the danger area of the machine is prohibited!

•

Before switching on the implement and starting, check the near area.

•

Pay special attention to children and animals. Make sure you have enough sight!

•

Before starting work, remove foreign objects from the surface to be worked. Pay attention to

other foreign objects during work and eliminate them in good time.

•

When working in enclosed areas, the safety distance to the border must be maintained so as

not to damage the machine or brushes.

•

When working in the immediate vicinity of public roads and paths, they should not be

approached longitudinally, but preferably as far as possible, as this minimizes the risk of injury

to third parties due to flying objects.

•

When working on public roads and squares or in the immediate vicinity, warning and danger

signs should be set up to alert third parties.

3.2.3

Before starting work

•

Before starting work, familiarize yourself with all the equipment and actuators and their

function, and make sure that all safety devices are properly installed and in the protective

position. It's too late during the work assignment!

3.2.4

During operation

•

Never leave the control room while driving!

•

Do not leave the operating station until the brushes of the attachment come to a standstill!

•

Do not make adjustments to the attachment during operation - risk of accident!

•

The transport of persons and objects is prohibited!

•

If, for example, the attachment has caught a foreign object and blocked it, stop the engine and

clean the attachment with a suitable tool! When intervening or cleaning the attachment, always

switch off the engine! Please observe the safety instructions of the self-propelled implement.

•

If the self-propelled implement or attachment is damaged, stop the engine immediately and

have the damage repaired.

3.2.5

Leaving the machine

•

By using chocks or, if necessary, by the parking brake, secure the machine against rolling away

when leaving.

•

Secure the device against unauthorized use!

•

Never leave the appliance unattended while it is still in operation!

3.2.6

Screw connections and tires

•

When working on the wheels, make sure that the device is safely parked and secured against rolling

away!

•

Check nuts and bolts regularly for tightness and retighten if necessary.

•

Repair work on the tires may only be carried out by qualified personnel and with suitable mounting

tools!

•

If the tire pressure is too high, there is a danger of explosion!

•

Check the air pressure regularly.

Safety

7

3.2.7

Coupling and uncoupling of implements

•

Only connect and disconnect implements with the engine switched off and the PTO switched

off.

•

When changing attachments and their parts, use suitable tools and wear gloves.

•

When mounting and dismounting, bring the required support equipment into the respective

position and ensure sufficient stability.

•

Secure the self-propelled work machine and the attachment against rolling away (parking

brake, wheel chocks).

•

When attaching attachments, there is a risk of injury (crushing). Special care is necessary.

•

Attach implements according to regulations and fix in the prescribed places.

3.2.8

Maintenance, cleaning and repair work

•

If guards and working tools are subject to wear, these must be checked regularly and replaced

if necessary.

•

Only use original spare parts from the manufacturer, as these correspond to the technical

requirements and thus the risk of accidents is minimized!

•

Cleaning with the high-pressure cleaner should be carried out so that the water jet is not held

directly in bearings, turned parts, grease nipples, shaft seals, wheel hubs, etc. After each

cleaning with the high-pressure cleaner, the lubrication points must be re-greased. In case of

infringement, the right to guarantee expires!

•

Check the moving parts for ease of movement and if necessary, grease them!

•

After maintenance and cleaning work, be sure to refit the guards and put them in the protective

position!

•

To avoid the risk of fire, keep the machine clean!

•

Check nuts and bolts regularly for tightness and retighten if necessary.

•

When carrying out maintenance, cleaning and repair work on the lifted device always make

sure that it is protected by suitable support elements!

•

Before carrying out any repairs, make sure that the hydraulic system is depressurised,

because fluids under pressure can penetrate the skin and cause serious injuries! Therefore,

seek medical attention immediately - risk of infection!

•

Repairs may only be carried out by qualified personnel.

•

Inspect hydraulic hoses at regular intervals for damage and aging and replace if necessary.

•

When welding the tractor or mounted equipment, disconnect the battery.

•

Repairs such as welding, grinding, drilling, etc. must not be carried out on supporting and other

safety-related parts such as frames, axles, etc.!

Safety

8

3.2.9

Pictograms used

Explanation of the pictograms used:

Before commissioning, read and observe the

operating instructions and safety instructions.

Never open or remove protective devices while the

engine is running!

Follow the instructions in the technical manual.

Smudge!

Touch machine parts only when they have come to a

complete stop.

Danger from passing parts while the engine is running -

keep safety distance!

Assembly

9

4 Disposal

The equipment must be disposed of in accordance with local, state, or local regulations.

Depending on the material, you can dispose of the parts in the form of residual waste, special

waste or recycling. The company Kersten Arealmaschinen GmbH assumes no disposal.

5 Warranty

The device is accompanied by a sales message, which among other things determines the time of the

start of the warranty period. When selling the device, please complete the sales message and send it

back to us within 14 days. If warranty claims are asserted without us having a sales message, no

warranty service will be provided.

Warranty claims should be submitted promptly, but no later than six weeks after the occurrence of the

damage, giving details of the purchase data, otherwise no warranty service will be provided.

Complaints must be confirmed by the company Kersten Arealmaschinen GmbH. Wear parts are

excluded from the warranty. In addition, the warranty expires in the case of improper operation, in the

event of no or incorrect maintenance work, when using inadmissible equipment and when using non-

original spare parts.

6 Recommendations

6.1

Lubricants

For engine and gearbox, use the specified lubricants (see under "Technical data").

For "open" lubrication points or nipple points we recommend to use biolubricant oil or biolubricant

grease. With the use of biolubricants you act ecologically correct, protect the environment and

promote the health of people, animals and plants.

6.2

Fuels

The built-up B & S or Honda engine can be easily operated with commercial unleaded normal and

premium gasoline and leaded premium gasoline.

Do not add oil to the gasoline.

If unleaded petrol is used for the environment, engines that are to be shut down for more than 30 days

should have their fuel drained completely to avoid resin residues in the carburettor, fuel filter and tank,

or to add a fuel stabilizer to the fuel.

6.3

Maintenance and repair

Your dealer has trained mechanics who perform proper maintenance and repairs. You should only

carry out major maintenance and repairs yourself if you have the appropriate tools and knowledge of

machines and internal combustion engines.

Assembly

10

7 Installation

7.1 Extension of KM 13050-22550 M-ABR 50 and KM 13050- 22550H-ABR 50

Danger!

Severe injuries to the operator or third parties may occur.

Switch off the tractor and remove the ignition key before mounting or dismounting the mounted sweeper.

Depending on the design of the front hydraulics, hook the FKM into the tractor implement triangle or the

two-point receptacle, whereby it may be necessary to adjust the connecting parts on the sweeping

machine side to the desired lifting height for the first time.

For easier mounting and dismounting of the FKM we recommend the two additional side parking supports

with wheels (special accessories).

7.2

Attachment of a KM 13050- KM 22550 M-ABR 50

Depending on the tractor type, the delivered PTO shaft may be too long. In this case, it must be shortened

according to the following steps.

Danger !

Damage to the attachment or to the tractor may occur. Use only the

supplied PTO shaft.

Note!

When installing the PTO shaft, also pay attention to the original instructions supplied by

the PTO shaft manufacturer.

Instructions for shortening and assembling the PTO shaft

Shortening the PTO shaft

1.

Pull apart the cardan shaft halves.

2.

Install one end of the PTO shaft on the tractor.

3.

Attach the other end of the PTO shaft to the implement.

Image 1 Image 2

4.

In the shortest working position, mark the piece to be sawn on one half of the PTO shaft. (Image 1)

5. Cut off the drive shaft guard to the mark. (Image 2 )

Assembly

11

Image5

Image 3 Image 4

6. Saw off the profile tube. Attention: the profile tube must be 10 mm longer than

the protection. (image 3)

7. Repeat steps 4. - 6. on the second PTO shaft half.

8. Deburr all cut edges. (image 4)

10. Slide the profile tubes together.

Mount PTO shaft

1.

Press and hold the locking pins on the outer forks.

2.

Slide the outer fork onto the PTO stub shaft.

3.

Release the locking pin.

4.

Move the PTO shaft back and forth until the locking pin clicks into place.

Image6

5.

Hook the drive shaft safety chains to a fixed part on the tractor and the

implement.

Depending on the version, the machines are equipped with a hydraulic swiveling device. Insert the

hydraulic hoses into the hydraulic sockets provided on the tractor.

Pay attention to the cleanliness of the plug-in couplings.

Service

12

Turning handle for

height adjustment g.

Support wheel roller

Spindle for height

adjustment Surface-

mounted side brush

Joint-wave

Side broom

Stabilizer

Bearing Shell

tension rod Container stop

7.3

Cultivation of a KM 13050-22550 H-ABR 50

Insert the two hydraulic lines (supply and return) for the sweeper drive into the hydraulic sockets on the

tractor.

Depending on the version, the machines are equipped with a hydraulic swiveling device. Insert the

hydraulic hoses into the hydraulic sockets provided on the tractor.

Pay attention to the cleanliness of the plug-in couplings.

7.4

Mounting dirt collector

Screw the two stops for the collection container left and right on the sweeper. Secure the supplied

rubber cloth on the upper front edge of the sweeper by means of a sheet metal rail. To do so, place

the sheet metal rail flush and screw together with M6 x 20 mm screws, 2 washers each and stop nut.

Hook the dirt collector into the holes provided on both sides with the help of the locking pins and

secure with clippings.

Hook in the hydraulic cylinder for the hydraulic tank emptying and with a Secure the folding pin. Route

the hydraulic hose towards the tractor. The length of the hose and the type of plug-in coupling to the

tractor depend on the type of tractor - please specify this when ordering!

7.5

Mounting side brush

Attention: Each delivered KM with side brushes is delivered without oil for transport reasons.

Make sure to top up with oil before using the KM otherwise oil pump damage will occur!

Please use hydraulic fluid with a viscosity of 46, which is biodegradable or an equivalent oil.

For mounting the hydraulic pump

First, install the two fixing screws of the gearbox (in the direction of travel, right), coupling of the side

broom on the gearbox side with thrust ring and Seegering.

Insert the feather key into the groove and attach the pre-assembled coupling to the gearbox

and secure with the washer and the screw.

Now the coupling pinion can be mounted on the pump side with the stop ring and the

Seegering.

Attach the pump with pump holder to the coupling and fasten the pump holder to the gearbox

holder with the two screws.

Service

13

Hydraulic

motor

sweeper

To the

sweeping

roller

Hydromotor

side brush

Hydrauli

c hose

return to

sweeper

side brush

Control

valve "A"

Tee

For mounting the hydraulic tank

first the tank on the sweeper housing

(in the direction of travel on the right)

Screw in top of existing holes.

Screw the suction hose 15L between

the tank filter side and the bottom of

the pump.

Mount the pressure hose between

the control unit on the tank and the

top of the pump.

To install the side brush arm, screw the

mounting plate to the right of the sump

edge in the holes provided there.

Hook in the side brush arm with a bolt

and nut. Connect the two hydraulic hoses

between the side brush and the hydraulic

tank.

Circuit diagram: Control valve "A" is used to set the sweeping roller speed.

Control valve "B" is used to set the sweeping roller speed.

Note:

Before carrying out the test run, retighten all hydraulic connections and top up the hydraulic oil (see

above) in the tank!

Hydrauli

c hose

supply to sweeper

Service

14

7.6

Installation of the water blasting device

Install the pre-assembled water jets with the mounting brackets - as shown in

the sketch.

a) Sweeper without collecting container: b) Sweeper with collecting container:

Jet

Headers Headers Clippings Jet

The distance between the two nozzles varies with the different working widths of sweepers. See

sketch.

Front view:

KM 1275: Distance of the water nozzles „a“ = 635mm

KM 1500: Distance of the water nozzles „a“= 750mm

a

Maintenance

15

8 Operation

8.1

Operating instructions - Sweeper

Adjust the two support wheels with the help of the turning handles in such a way that the roller

brushes a about 4 cm wide strip on the ground depressed. It is important to pay attention to the

same setting of the two support wheels according to the marking on the scale graduation!

Note: A sweeping roller set too tight will not produce better sweeping results.

Attention: Never store the sweeper on the broom.

For easier storage and installation of the sweeper we recommend the additional two support

wheels, which are available as special accessories.

8.2

Dirt collecting setting

Install the sweeper with container on the carrier vehicle and adjust the top link so that

the trailing edge of the container is approx. 4 cm and the leading edge

have about 7 cm ground clearance.

Depending on the degree of wear of the sweeping roller, the collecting container must be placed in

the corresponding holes so that the setting dimensions: 4 cm and 7 cm are maintained. Here, the

container may be better higher than too deep.

Attention: Please adjust carefully for very uneven ground conditions!

8.3

Side brush - setting

Please adjust the side broom only when the main broom and the dirt collector are set.

The height is adjusted by operating the spindle on the mounting plate.

The best sweeping performance with a side brush results in a sweeper that is slightly tilted

towards the middle of the road.

When not in use, fold up the side broom and secure it, this is also the storage position.

When dismantling the side broom and operating the sweeper without a side brush, it is essential

that the hydraulic hoses are put into circulation.

Make sure that the hydraulic connectors are clean!

For storage of the sweeper be sure to relieve the sweeping roller!

Maintenance

16

9 Maintenance

9.1

General

Danger!

Personal injury or damage to the machine may occur.

Before using the machine, check all safety-related parts and the hydraulic connections.

9.2

Maintenance

●

The sweeper must be subjected to regular maintenance.

●

After carrying out the work, all dismantled safety devices must be removed

be properly installed again.

●

After the first 5 hours of operation, check all bolts and bolts

Bolt connections and the tension rod of the sweeping roller.

●

Lubricate or lubricate all moving parts.

●

Check the hydraulic connections for leaks before each use.

●

Check hydraulic connections for the first time after 5 operating hours, tighten if necessary!

Important NOTE:

Only tightening has no success !!!

Please release a leaking hydraulic fitting first, then move the hose or screw connection. Now

the screw can be tightened again.

Maintenance of the PTO shaft:

The PTO shaft must be serviced regularly.

Observe the instructions in the enclosed operating instructions of the cardan shaft

manufacturer.

9.3

Daily test

●Check the safety elements and moving parts for wear before each use.

●Check the hydraulic connections and lines.

●Perform a test run before each use.

●Clean the device after each use.

●Sweeping roller: Turn up both support wheels for storage,

until the sweeping roller is unloaded.

●Side brush: Store only when lifted.

9.4

Maintenance after 20 or 100 operating hours or longer downtime

●

At regular intervals and always at the beginning and end of the season

●

the moving parts of the unit are greased or oiled.

●

Check the tension of the drive chain and grease slightly.

●

Grease the spindle of the wheels.

●

Make sure the gear unit is tight.

●

Hydraulic tank for side brushes: Replace the hydraulic oil and the hydraulic filter for the first time

20 operating hours then change every 200 hours.

9.5

Installation of the sweeping roller

First disassemble the tie rod on the side. Then loosen the three screws of the bearing shell

and remove the bearing. Remove the drive tube, insert the broom into the machine. Now

mount the drive tube with bearing in reverse order.

Technical specifications

17

10 Technical specifications

10.1

Sweeper

Type KM 13050

M-ABR 50

KM 14750

M-ABR 50

KM 16550

M-ABR 50

KM 19050

M-ABR 50

KM 22550

M-ABR 50

working width 150 cm 147 cm 165 cm 190 cm 225 cm

Sweeping

roller

diameter

50 50 50 50 50

mechanical. drive

●

●

●

●

●

hydraulic drive

Type KM 13050

H-ABR 50

KM 14750

H-ABR 50

KM 16550

H-ABR 50

KM 19050

H-ABR 50

KM 22550

H-ABR 50

Sweeping roller

diameter 150 cm 147 cm 165 cm 190 cm 225 cm

mechanical.

drive 50 50 50 50 50

hydraulic drive

Sweeping roller

diameter

●

●

●

●

●

10.2

Scope of delivery as standard

- Kom bic roller with poly-twist trim five-row

- Rubber splash flap

- Hydraulic swivel device

10.3

Additional equipment

- Height-adjustable ABS support wheel for easy mounting and dismounting

- 2 parking supports with rollers

- Dirt collection container with hydraulic container emptying

- Surface-mounted side brush 50 cm Ø (hydraulically driven)

- sprocket for speed increase (snow sweeping)

- Water sprinkler with 100 liter tank or 200 liter tank

- Further sweeping rollers on request

- Reserve technical changes! -

18

11 EG – Konformitätserklärung

CE Déclaration de conformité

EC Declaration Conformity

EG conformiteitsverklaring,0

D

F

GB NL

Wir Nous We Wij

Kersten Arealmaschinen GmbH

Empeler Straße 95

D- 46459 Rees

erklären, dass das

Produkt

déclarons que le

produit

herewith declare

that the product

verklaren dat het

produkt

Frontkehrmaschine Balayeuse de front Front sweeper

machine

Frontveegmachine

KM 13050; 14750; 16550; 19050; 22550 M-ABR-50

KM 13050; 14750; 16550; 19050; 22550 H-ABR-50

mit allen einschlägigen

Bestimmungen der

EG-Maschinenricht-

linie 2006/42/EG in

Übereinstimmung ist.

satisfait à l'ensemble

de la directive machines

2006/42/CE.

fulfiles all relevant

provisions of Directive

2006/42/EC.

voldoet aan alle

toepasselijke be-

palingen van EG-

Machinerichtlijn

2006/42/EG.

Die Maschine ist auch

in Übereinstimmung

mit allen einschlägigen

Bestimmungen der fol-

genden EG-Richtlinien:

Cette machine satisfait

également à toutes les

dispositions pertinentes

des directives CE

suivantes:

The machinery is also

in compliance with all

relevant provisions of

the following EC

directives:

De machine is ook

in overeenstemming

met alle toepasselijke

bepaligen van de vol-

gende EG- richtlijnen:

Weiterhin wurden fol-

gende Normen ange-

wendet:

En outre, les normes et

spécifications techniques

suivantes ont été utilisées:

The following

harmonised standards

apply:

Volgende geharmoni-

seerde normen warden

gehanteerd:

EN ISO 12100:2010

Herr Monsieur Mr. De heer

Dipl. Ing. (FH) Robert Bosch

Empeler Straße 95

D- 46459 Rees

ist bevollmächtigt est autorisé à constituer is authorised to is gemachtigd het

die technischen Unter- la documentation compile the technical technische dossier

lagen zusammenzu- Technique conformémen

t

file according to Annex samen te stellen.

stellen. à l'annexe VII A. VII A.

Rees, 16.04.2014

Geschäftsführer

Declaration of conformity

NOTE:

This manual suits for next models

10

Table of contents

Popular Floor Machine manuals by other brands

Tennant

Tennant 5200 Operator and parts manual

Weber

Weber CLEAN TRACK FloorLine CT Quadro Mini manual

Tennant

Tennant NOBLES EX-CAN-15-HP Operator's manual

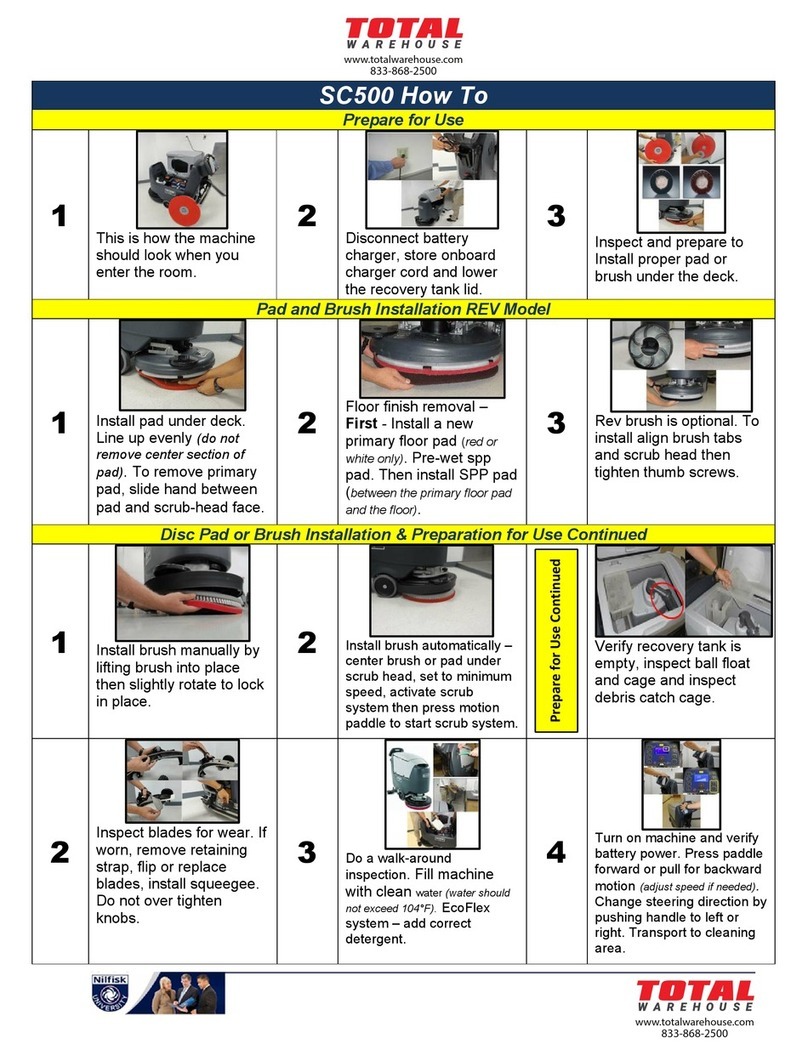

Nilfisk-Advance

Nilfisk-Advance SC500 How-to guide

MasterCraft

MasterCraft MTHC-20JDLX Safety, Operation & Maintenance Manual/Parts List

Castex

Castex BR-1600 Operator and parts manual