WerkMaster Stealth User manual

OPERATOR’S MANUAL

IMPORTANT:

Read before using your new WerkMaster Burnisher

WerkMaster Grinders and Sanders Inc.

6932 Greenwood Street, Burnaby, BC V5A 1X8

tel: 604.629.8700 | toll free: 1.866.373.WERK | fax: 604.444.4231

www.werkmaster.com | email: support@werkmaster.com

!!LIABILITY LIMITATIONS

The remedies of the user set forth under provisions of warranty outlined at

the end of this manual are the exclusive and total liability of WerkMaster

Grinders and Sanders Inc, herein referred to as WerkMaster. with the

respect to their sale of the equipment and service furnished hereunder, in

connection with the performance or breach thereof, or from the sale,

delivery, installation, repair or technical direction covered by or furnished

under the sale, whether based on contract, warranty, negligence,

indemnity, strict liability, or otherwise shall not exceed the purchase price

of the unit of equipment upon which such liability is based.

WerkMaster will not in any event be liable to the user, any successors in

interest or any beneficiary or assignee relating to this sale for any

consequential, incidental, indirect, special or punitive damages arising out

of this sale or any breach thereof, or any defects on, or failure of, or

malfunction of the equipment under this sale based upon loss of use, lost

profits or revenue, interest, lost goodwill, work stoppage, impairment of

other goods, loss by reason of shutdown or non-operation, increased

expenses of operation of the equipment, cost of purchase or replacement

power of claims of users or customers of the user for service interruption

whether or not such loss or damage is based on contract, warranty,

negligence, indemnity, strict liability, or otherwise.

WerkMaster reserves the right to modify, alter and improve any part or

parts without incurring any obligation to replace any part or parts

previously sold without such modified, altered or improved part or parts.

No person is authorized to give any other warranty or to assume any

additional obligation on WerkMaster’s behalf unless made in writing and

signed by an officer of WerkMaster.

USE ONLY GENUINE WERKMASTER PARTSANDACCESSORIES

FOR YOUR OWN SAFETY, THE SAFETY OF OTHERS AND THE LIFE

OF YOUR MACHINE.

!

OPERATOR’S MANUAL

1

!

CONTENTS

Introduction...........................................................................................................3

Machine Descriptions...........................................................................................4

Specifications .......................................................................................................4

Safety Precautions................................................................................................5

Danger...................................................................................................................5

Warning.................................................................................................................7

Caution..................................................................................................................7

Operator Responsibilities......................................................................................8

Propane Safety Information.................................................................................9

Facts About Liquid Propane Gas (LPG)................................................................9

Facts About Propane Tanks..................................................................................9

Recommended Purge Procedures....................................................................... 9

Filling Propane Tanks..........................................................................................10

Storing Propane Tanks........................................................................................11

Storing Machine...................................................................................................11

Transporting Machine..........................................................................................11

Engine Emissions and Carbon Monoxide Safety.............................................12

CO Exposure Limits.............................................................................................12

Methods To Reduce the Risks of CO Poisoning..................................................12

Machine Components.........................................................................................13

Controls and Instruments.....................................................................................13

Engine Ignition Switch.........................................................................................14

Stealth ACCU-Sense Emissions Monitoring System...........................................15

Spectre AUTO-Sense Emissions Monitoring System..........................................17

Hour Meter/Tachometer.......................................................................................18

EZ Bak Tilt Operation...........................................................................................19

Fuses...................................................................................................................20

Machine Operation..............................................................................................21

Pre-Operation Checklist.......................................................................................21

Installing the Propane Tank..................................................................................21

Starting the Machine............................................................................................22

Burnishing............................................................................................................23

Idling and Stopping the Machine.........................................................................24

Maintenance.........................................................................................................24

General................................................................................................................24

Inspecting the Oil Level.......................................................................................24

Changing the Oil..................................................................................................25

Replacing the Oil Filter.........................................................................................26

Inspecting and Replacing the Spark Plug............................................................27

Inspecting and Replacing the Oil Filter................................................................27

Inspecting and Replacing the Fuel Hose.............................................................28

Changing the Engine Dust Filter..........................................................................29

Maintaining the Cooling Fin.................................................................................29

Inspecting and Changing the Pad and Pad Holders............................................30

Maintaining the Belt.............................................................................................30

Maintaining the Battery........................................................................................31

Adjusting the Wheels...........................................................................................32

Cleaning the Dust Bag STEALTH ONLY..............................................................32

Maintenance Schedule........................................................................................33

Troubleshooting...................................................................................................34

Limited Warranty..................................................................................................36

Warranty...............................................................................................................37

Safety Awareness Form for Propane Machines................................................39

OPERATOR’S MANUAL

2

!

NTRODUCTION

Congratulations on your purchase of a WerkMaster Propane Burnisher.

WerkMaster machines allow professional surface prep, polishing,

grinding, edging, buffing and restoration of virtually any surface material,

concrete, terrazzo, and stone. This manual is provided to assist you in the

operation and maintenance of your WerkMaster machine.

WerkMaster is dedicated to our customers, their safety, and to providing

information, services, and products that meet their needs.

Read this manual and all safety precautions before attempting to

operate or perform service on your WerkMaster machine. Failure to

follow the safety precautions may result in damage to the machine,

severe personal injury or death.

If you or your operator cannot read English, have this manual explained

fully before attempting to operate the machine.

It is the owner/operator’s responsibility to ensure the air exchange system

installed in any location where a propane burnisher is being operated is of

sufficient capacity and quality to support the use of such a machine.

OSHA/WCB and other county, state, federal or provincial agencies publish

guidelines on the subject that are usually found in the in the possession of

the respective owners and/or parent companies of any location or chain of

locations. Failure on the part of the owner/operator to ensure that a

propane grinder/polisher can be operated safely in a given location may

lead to sickness or even loss of life.

This Operator’s Manual has been prepared for instructional purposes

only. WerkMaster does not claim or assume any responsibility for the

operator’s action or safety.

To be completely aware of what local authorities require, contact the

OSHA or WCB agency in your community.

IMPORTANT

OPERATOR’S MANUAL

3

!

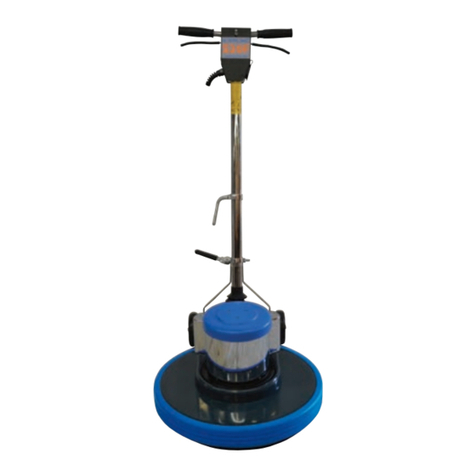

MACHINE DESCRIPTIONS

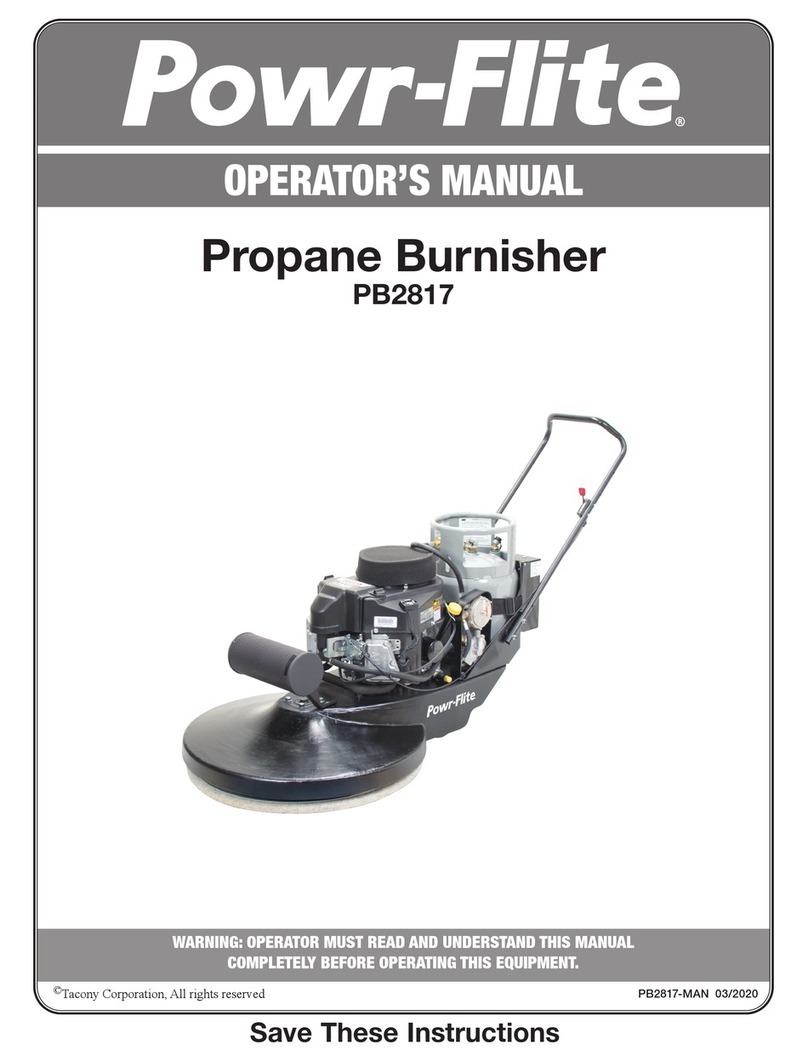

WerkMaster Propane Burnishers include the Stealth and the Spectre

models. The WerkMaster family of machines include the Scarab, Termite

XT, Viper XT, Raptor XT, TITAN XT and the COLOSSOS XT models. To

see the complete family of WerkMaster machines, informational videos,

tooling guide, chemicals and accessories visit our website at

www.werkmaster.com.

STEALTH

■Accu-Sense™ Emissions Monitoring System with ClearSKY

Technology

■Ergonomic design improves form and function

■Catalytic muffler exceeds EPAand OSHAminimum requirements

■Adjustable handle and soft tread wheels for optimal comfort and

results

■Easy access battery and oil reservoir for no fuss maintenance

■EZ Bak™ action allows for easy pad change

■Improved engine dust filter reduces filter cleaning by 50%

■Bail throttle with electric clutch for easy start-up and smooth

operation

■DustMizer™ centrifugal dust collection system

■American made aluminum castings with durable steel skirt

■Featuring an 18HP 603cc engine from Kawasaki with a 2 Year

Warranty

SPECTRE !

■Auto-Sense™ Emissions Monitoring System with ClearSKY

Technology

■Catalytic muffler exceeds EPAand OSHAminimum requirements

■Adjustable handle and soft tread wheels for optimal comfort and

results

■Easy access battery and oil reservoir for no fuss maintenance

■EZ Bak™ action allows for easy pad change

■American made aluminum castings with durable steel skirt

■Standard electric clutch

■Featuring an 18HP 603cc engine from Kawasaki with a 2 Year

Warranty

SPECIFICATIONS

MODEL

STEALTH

21”

STEALTH

28”

SPECTRE

21”

SPECTRE

28”

Dimensions

(l x w in)

(l x w cm)

58 x 24.5

148 x 62.25

65.6 x 31.5

167 x 80

56 x 24.5

142.25 x 62.25

61.5 x 31.5

156 x 80

Weight (lb/kg)

242 / 110

262 / 119

215 / 97

234 / 106

Pad Size (in/cm)

21 / 53

28 / 71

21 / 53

28 / 71

Pad Speed (RPM)

2000

1700

2000

1700

OPERATOR’S MANUAL

4

!

SAFETY PRECAUTIONS

Failure to read this manual and all safety precautions before attempting

operate your WerkMaster machines may result in severe personal injury

or death.

This machine is manufactured for commercial use only.

This machine is designed and manufactured for indoor use in burnishing

hard floor surfaces. WerkMaster does not recommend use of this machine

in any environment other than an indoor environment. The machine is

designed to burnish most modern types of flooring including composition

tile, stone, marble, terrazzo, and resilient floor covering, and some coated

wood floors. Even though NFPA 11.13.2.3 (b) says,”the use of floor

maintenance machines in buildings frequented by the public, including the

times when such buildings are occupied by the public, shall require the

approval of the authority having jurisdiction” WerkMaster suggests usage

when occupancy of a given work area is minimal.

DO NOT use:

•In occupied nursing homes, hospitals, daycare centers, etc.

•By unqualified or untrained personnel

•Unless properly maintained and adjusted

•On areas with obstructions such as thresholds, floor outlet boxes,

etc.

•In areas where loose debris or other objects are present

•In rooms and areas without proper ventilation

DANGER indicates severe bodily injury or death may occur to you or

other persons if safety precautions are ignored or not adhered to.

Read and observe all DANGER statements found in the Operator’s

Manual and on the machine.

‣Operate this machine in a well-ventilated area. It is the responsibility of

the machine operator, machine owner, and the site manager to ensure

that the air exchange system where the machine is to be used is in

compliance with local building codes and is operated properly. Failure to

operate the machine in a well-ventilated area could lead to sickness,

injury, or death from carbon monoxide (CO) exposure

‣This machine emits CO, a colorless, odorless, non-irritating gas. The

first symptoms of CO exposure include headache, drowsiness,

dizziness, and nausea. If you should experience any of these symptoms

while operating this machine, shut off the machine and move to a well-

ventilated area. Have the machine tested for CO emissions by a

qualified service technician before using it again.

IMPORTANT

DANGER

OPERATOR’S MANUAL

5

!

‣Prolonged or high exposure to CO may result in vomiting, confusion,

and collapse in addition to loss of consciousness and muscle

weakness. If such symptoms occur, call 911 for emergency medical

attention. If you have experienced these symptoms DO NOT operate

this machine or any other propane machine until cleared by a physician.

Excessive exposure to CO may result in death.

‣Propane is highly flammable. If you smell propane, immediately shut the

machine off and take it outside the building.

DO NOT:

• Use the machines again until a qualified service technician

has corrected the propane leak.

• Use an ignition source such as a cigarette lighter near the

propane machine.

• Smoke near the propane machine.

• Vent a propane tank inside a building.

• Store propane tanks inside a building.

‣The machine has parts, including the pad assemblies, that can cause

severe injury if touched while they are moving.

DO NOT:

•Allow any part of the body or clothing to come into

contact with the machine while parts are moving

•Try to change attachments while the machine is running

•Allow other people to come near the machine while it is in

operation

•Allow the machine to run attended

•Leave the machine in a place where unauthorized or

untrained personnel could use the machine

•Run the machine with the pad center damaged or missing

•Operate the machine if the machine has loose parts

•Run the machine with unsecured guards or shields

‣Federal law and California State law prohibits the following acts or the

causing thereof:

1) the removal or rendering inoperative by any person other than

for purposes of maintenance, repair, or replacement of any

device or element of design incorporated into any new engine for

the purpose of emission control prior to its sale or delivery to the

ultimate purchaser or while it is in use, or

2) the use of the engine after such device or element of design

has been removed or rendered inoperative by any person.

Among the acts presumed to constitute tampering involve the

parts/systems listed below:

•Throttle body and internal parts

•Spark plugs

•Magneto or electronic ignition system

•Air cleaner elements

•Crankcase

•Cylinder heads

•Breather chamber and internal parts

•Intake pipe and tube

•Regulator

•Fuel lock-off

•Carburetor and internal parts

•Fuel filter element

NOT an all-inclusive list.

OPERATOR’S MANUAL

6

!

DO NOT tamper with the original emission related parts.

Tampering with the Emission Control System is prohibited and will

VOID THE WARRANTY.

WARNING indicates injury may occur to you or other persons if

safety precautions are ignored or are not adhered to. Read and

observe all WARNING statements found in the Operator’s manual

and on the machine.

‣Modifications or alterations to the machine can lead to personal

injury or damage to the machine. DO NOT make unauthorized

modifications or alterations to the machine; this VOIDS ALL

WARRANTIES.

‣The muffler and engine become hot while in operation and remain

hot long after the machine is shut off; this can cause severe burns.

DO NOT touch these parts of the machine until they have

cooled.

‣To avoid injury safety goggles, safety shoes and safety clothing are

recommended while operating the machine.

‣Continuous exposure to high noise levels can cause hearing loss.

Hearing protection is recommended while the machine is in operation.

‣Machine vibration may cause tingling or numbness in the fingers or

hands. Gloves are recommended to reduce machine vibration. If tingling

or numbness persists, shut off the machine. If the vibration is caused by

loose parts, adjust or tighten these parts before using the machine

again.

CAUTION indicates damage may occur to the machine or to other

property if safety precautions are ignored or are not adhered to. Read and

observe all CAUTION statements found in the Operator’s manual and on

the machine.

‣NEVER overfill the propane tank. ONLY fill to 80%. Overfilling the

propane tank is the number one cause of problems with a propane

machine. Overfilling may cause the engine to run poorly or not at all.

‣A dirty engine filter can cause overheating. Check and replace following

recommended maintenance schedule page .

‣Overheating can be caused by dirty or insufficient or low levels of oil.

Check oil before each use, and fill or change as needed.

WARNING

CAUTION

OPERATOR’S MANUAL

7

!

‣NEVER overfill the engine with oil. Overfilling can cause irreparable

damage to the engine.

‣DO NOT engage starter for more than 5 seconds. Allow a 10 section

cool down for second failed start-up attempt.

‣Perform all recommended scheduled maintenance. Regular

maintenance of your propane powered floor machine is necessary to

keep it safe working condition.

‣Before starting machine ensure all safety devices are in place and

functioning properly. Before starting machine do a maintenance and

safety check. See page .

‣When using machine, go slowly on inclines and slippery surfaces. Use

care when operating machine in reverse.

‣When servicing machine, stay clear of moving parts. DO NOT wear

loose clothing when working on machine. Block machine wheels before

raising or jacking up machine. Use hoist stands that will support the

weight of the machine. Wear eye and ear protection when using

pressurized air or water. Disconnect battery connections before

servicing machine. Only use replacement parts supplied by WerkMaster

or a WerkMasterAuthorized Distributor or Service Center.

DO NOT operate this machine before carefully reading and understanding

the operation manual.

The operator is responsible for performing the recommended daily

maintenance and checkups of the machine to keep it in good working

condition. The operator must inform the service mechanic or supervisor

when recommended maintenance procedures are required as described

in the MAINTENANCE section of this manual.

We recommend taking advantage of a service contract from your

WerkMasterAuthorized Distributor or Service Center. Order parts and

supplies only from an Authorized WerkMaster Distributor.

During and after operation, perform the recommended daily and hourly

procedures outlined in the Maintenance Chart.

OPERATOR’S MANUAL

8

!

Operator

Responsibilities

PROPANE SAFETY INFORMATION

As a fuel, propane gas is unmatched for both safety and dependability. It

has been used a a domestic household fuel for over half a century, and for

over thirty years as an internal combustion engine fuel.

Propane is a highly flammable fuel that is contained under pressure as a

liquid. Vaporized gas has a similar explosive force to gasoline and

mixtures as low as 2% LP gas to air may be ignited in a closed

environment. Care should be exercised to avoid escaping vapor as it can

freeze skin and cause frost bite. Vaporized fuel is heavier than air and will

collect in the lowest confined space available.

Propane tanks are constructed according to ASME or Federal DOT

#4ET20 pressure safety codes. Including the tank, all valves and fittings

are UL listed. Propane gas is noncorrosive and will not rust the inside of a

tank. Should the tank exterior become damaged or rusted, discontinue

use. DO NOT tamper with the tank gauges or safety relief valves. NEVER

use a tank not intended for use with a propane burnisher. DO NOT

substitute tanks that are used with a barbecue grill, etc. WerkMaster

recommends having propane tanks tested once a year by an authorized

National LP GasAssociation propane dealer.

The fuel tank is supplied directly from the manufacturer and is void of fuel.

The tank must be purged at the time of the first fill. Local propane fuel

vendors should be familiar with this operation and will provide this service.

DO NOT attempt to repair the tank. Return the tank to your propane if

necessary.

!!!!!

New containers may contain vapor, air, or other contaminants. It is

essential that these be removed before filling the container and putting it

into service. Air in the container will cause abnormally high pressure, with

the result that the pressure relief valve may open. Air in the system is also

likely to cause a lean mixture, making ignition difficult. If a tank is

suspected of being depressurized or open to the atmosphere for a period

of time, it must be re-purged.

See an authorized propane dealer for proper purging of your new tank.

Symptoms of a non-purged propane tank:

•Relief valve opens due to over-pressurized propane tank creating

hazardous situation

•Moisture in the propane tank

•Burnisher operates initially but shuts down when the fuel mixture

becomes too lean.

WARNING

OPERATOR’S MANUAL

9

!

Facts About

Liquid Propane

Gas (LPG)

Facts About

Propane Tanks

Recommended

Purge Procedures

ALWAYS have an authorized propane dealer fill your tank.

NEVER OVERFILL THE PROPANE TANK. ONLY FILL TO 80%.

OVERFILLING PROPANE TANKS IS HAZARDOUS. EXPANSION

MUST BE ALLOWED FOR.

FILL THROUGH THE SERVICE VALVE ONLY.

These machines use a 20 lb (9.1 kg) capacity aluminum or steel cylinder,

which meets the DOT4E240 standards. These standards are also listed

by UL. In addition, the steel cylinder meets meets European TPED

specifications and is CE compliant.

The engine and the fuel system on your WerkMaster machine are

designed to run on vapor propane NOT liquid propane. Liquid propane

and vapor propane are NOT interchangeable. Interchanging the fuel will

VOID THE WARRANTY.

Use a vapor withdraw cylinder NOT a liquid withdraw cylinder on this

machine. The use of a liquid withdraw cylinder on a vapor withdraw

system could freeze the regulator and create a fire hazard.

If the regulator freezes, stop the burnisher and take the tank outside and

inspect. Use gloves or pliers to open the bleeder valve and purge the tank

until only vapor is escaping.

Pressure Liquid Level

Relief Gauge Sight Gauge

Bleeder Service Valve Service Valve

Valve

ONLY authorized, trained personnel should have access to propane tanks

and machines.

WARNING

OPERATOR’S MANUAL

10

!

Filling Propane

Tanks

Propane tanks should NOT be stores in buildings used by employees, the

public or frequented by anyone passing through.

When not in use tanks should always be stored outside in an upright position

in a secure, tamper-proof, steel mesh storage cabinet. The cabinet may be

located next to the building, but with at least five (5) feet (1.5 m) of space

between the cabinet and the nearest building opening (door or window).

NEVER store spare propane tanks in an enclosed van or trailer, or near

an open flame or heat-producing device..

PROPANE TANKS SHOULD ALWAYS BE INSTALLED, USED.

TRANSPORTED AND STORED IN AN UPRIGHT POSITION.

The National Fire Protection Association (NFPA) Standard for Storage and

Handling of LP Gas is the appropriate authority for safe propane use.A

copy of this publication is available through the National Fire Protection

Association (1.800.344.3555) or www.NFPA.org.

Store the machine in a dry location, temperature not to exceed 120º F

(50º C), away from objects that may fall and damage it, and away from

open flames or heat-producing devices.

NEVER store machine with propane tanks installed.

Make sure the machine is properly cleaned before storing.

When transporting a propane-powered machine with the propane tank

installed, the tank should be securely fastened and the service valve

closed. Any propane tanks not installed should be upright and securely

fastened to avoid movement and damage.

Check the propane tanks for over-filling BEFORE transporting; If over-

filled, use the bleeder valve to vent the excess propane outside in a safe

area.

When loading onto or unloading off of a truck or trailer, turn the machine

OFF.

ONLY use a truck or trailer that will support the weight of the machine.

Block the wheels and tie the machine securely to the truck or trailer.

OPERATOR’S MANUAL

11

!

Transporting

Machine

Storing Machine

Storing Propane

Tanks

ENGINE EMISSIONS AND CARBON MONOXIDE SAFETY

All engines powered by by LPG (Liquid Propane Gas), including this engine,

Carbon Monoxide (CO). it is a FATAL POSION gas that is colorless, odorless,

tasteless, and non-irritating. It is produced by incomplete combustion of

carbonaceous material such as LPG.

Failure to provide for proper venting of CO produced during the operation

of combustion powered engines may result in SERIOUS INJURY OR

DEATH to the operator and those in the contaminated area.

The effects of CO can experienced at different exposure levels,

depending on the health of the individual. Conditions that affect the

tolerance of the individual are smoking, age, temperature, humidity, and

other conditions.

Symptoms include lightheadedness, confusion, headaches, vertigo,

drowsiness, dizziness and nausea.

If the operator experiences any of these symptoms STOP USING THE

MACHINE IMMEDIATELY. Move to a well-ventilated area. If symptoms

persist, get medical attention.

Prolonged or high exposure to CO may result in vomiting, confusion, and

collapse in addition to loss of consciousness and muscle weakness; call

911 for emergency medical attention. If you have experienced these

symptoms DO NOT operate the machine or any other propane machine

until cleared by a doctor. Excessive exposure to CO may result in death.

All distributors, owners, and operators should be aware of the potential

effects of CO and the methods used to prevent over-exposure.

Please refer to OSHA, WCB or local workplace industry guidelines for CO

exposure limits.

Air Exchange and CO Diffusion

CO does not mix with air on its own. Air currents can “stir” the CO and

dilute the concentration values by mixing it with the available air. Stirring

can occur by walking around and with the use of fans and ventilation

systems.

Application Considerations

Consider the operation you are performing and the size of the area to be

worked. A low movement operation in a smaller area will increase the

build-up of the CO, while a much quicker operation over the same area

may not have the same potential for CO build-up.

Stirring or CO mixing MUST be forced by the use of fans in order to

reduce the high concentration of CO when activity is concentrated to a

smaller area while performing a low movement operation.

DANGER

OPERATOR’S MANUAL

12

!

Methods to Reduce

the Risks of CO

Poisoning

CO Exposure

Limits

Air Quality Monitoring

Use of a monitor/detector is essential for the safe operation of any

equipment that has the potential to produce CO. See local regulations for

the approved monitors/detectors and their correct methods of use.

Room Size and Time Estimations

The concentration and volume of CO production, the size of the area, and

the amount of air exchange are factors involved with determining safe

time limits for operation in a specific room size.

The smaller the work area and the slower the movement, the greater the

build-up of CO. Fans MUST be used to stir the air and reduce the

concentration of CO.

Maintenance of Equipment

LPG engines are dependent on engine tune-ups and air filter

replacements. CO concentration (production) increases when the air to

fuel ration becomes fuel rich. Follow the recommended Maintenance

SChedule for the engine.

CO Safety Equipment Available

WerkMaster propane machines are equipped with a catalytic muffler and

an ACCU-Sense monitoring system on the Stealth and an AUTO-Sense

monitoring system on the Spectre to reduce the CO emissions and

promote a safer work environment.

MACHINE COMPONENTS

For the STEALTH:

Bail Throttle Hour Meter Key Switch

Handle Pivot Knob ACCU-Sense Light Display

For the SPECTRE:

AUTO-Sense

Emissions

Monitoring

System

!!!!!!! Engine

Throttle

!

OPERATOR’S MANUAL

13

!

Controls and

Instruments

The STEALTH and SPECTRE feature a key switch ignition.

For the STEALTH:

•START: Turn the key clockwise to START to engage the engine starter

motor. Once the engine starts release the key. ALWAYS start the

machine with the bail throttle in the SLOW IDLE position.

•RUN: This is the position of the key when the engine is running.

•OFF: Turn the ignition key to the OFF position to stop the engine.

ALWAYS close the propane tank valve to stop the engine, then turn

the ignition switch OFF.

DO NOT try to start machine with the bail throttle in the operating position.

After the engine has started, pull the bail throttle to the operating position.

The clutch will engage automatically and the engine will throttle to the

right speed. DO NOT pull the bail throttle with the burnishing head to the

floor.

Release the bail throttle; the clutch will automatically disengage and the

engine speed will return to idle.

WARNING

OPERATOR’S MANUAL

14

!

Engine Ignition

Switch

For the SPECTRE:

•START: Turn the key clockwise to START to engage the engine starter

motor. Once the engine starts release the key. ALWAYS start the

machine with the engine throttle in the SLOW idle position.

•RUN: This is the position of the key when the engine is running.

•OFF: Turn the ignition key to the OFF position to stop the engine.

ALWAYS close the propane tank valve to stop the engine, then turn

the ignition switch OFF.

The engine throttle controls the engine speed. To increase the engine

speed, move the hand lever forward. For the idle position pull the lever

back.

The Stealth ACCU-Sense is an emissions monitoring device that monitors

the exhaust emissions and will shut the engine down if the emission levels

are too low or too high.

After engine starts, the YELLOW alert light will flash for a 3 minute warm-

up cycle of the ACCU-Sense system. The machine may be operated

during the warm-up period. After the warm-up cycle, the alert light will go

out. None of the ACCU-Sense lights will be illuminated as long as the

machine is running safely.

Any light that is on when the engine stops will remain illuminated for 20

seconds to indicate the reason for the machine shut down.

OPERATOR’S MANUAL

15

!

STEALTH

ACCU-Sense

Emissions

Monitoring System

OIL: The light will come on when there is low oil pressure. If the engine

looses oil pressure, the engine shuts down until the condition is corrected.

The light comes on each time the engine is stopped.

TILT/IDLE: The light will come on when the machine is tilted to the pad

change position and the engine shuts down. If the machine is allowed to

idle for more than 4 minutes, the light flashes for 1 minute, then the

engine shuts down.

RED ACCU-SENSE SERVICE: If carbon monoxide levels exceed a pre-

set level, the light will flash. The machine will shut down after the light

flashes continuously for 1 minute. If the machine does not operate

normally after the engine air filter is checked and cleaned, it must be

serviced by a qualified technician.

YELLOW ACCU-SENSE ALERT: If the light comes on during normal

operation, check and clean the engine air filter. Check the carburetor air

filter for holes, tears, or punctures and replace if damaged. If the light still

remains on, the machine must be serviced by a qualified technician.

OXYGEN SENSOR: If light comes on during normal operation, check the

oxygen sensor wire for a snug fit into the harness and for a snug fit of the

harness into the ACCU-Sense board. If the light still remains on, the

machine must be serviced by a qualified technician.

TURN GAS OFF: Light comes on to remind the operator to turn off the

gas after the engine shuts down.

BATTERY: The light comes on when the battery voltage is low indicating

the need to service the charging system.

The oxygen sensor must reach operating temperature before it will start to

send signals to the ACCU-Sense module. This warm-up period is

approximately 3 minutes. After the initial 3 minutes, the module will start

evaluating the signal from the oxygen sensor. If the module receives an

abnormal reading for a period of 1 minute, the unit will shut down.

If the machine is also allowed to idle for more than 4 minutes, an indicator

light will flash for 1 minute and then the engine will shut down. If this

happens, turn the key to the OFF position for several seconds to clear the

ACCU-Sense module and restart the machine.

Once the engine has started, advance the bail throttle to operating

position and start the operation. With the engine at full throttle, under load,

the signal from the oxygen sensor should be within the normal operating

ranges for safe operation.

If the engine’s air intake filter needs to be serviced, or an over-filled

propane tank has been installed by mistake, or there is a problem with the

fuel system that causes the oxygen sensor’s signal to be out of range,

ACCU-Sense will shut the unit down after 1 minute. The unit can be re-

started after clearing the module by turning the key switch OFF. If

corrections have not been made to the unit, ACCU-Sense will continue to

shut the unit down until the problem is corrected.

OPERATOR’S MANUAL

16

!

Engines tend to go to a lean burn if allowed to idle for even short periods.

Even at high idle speeds most engines will continue to lean downward. it

is always best to shut the engine off when it is not being used to do work.

Remember, the engine is always creating emissions as long as it is

running.

The best manner to operate a unit equipped with ACCU-Sense is as

follows:

•With the bail throttle in the idle position, turn the key switch to the

START position. Once the engine starts, advance the bail throttle to

the operating position.

•When ready to stop operation, release the bail throttle. If the unit will not

be used within 45 seconds, turn the key switch to the OFF position, or

if the unit will not be returned to service within a few minutes it is best

to turn the gas valve on the tank off first and let the engine consume

all fuel that is in the lines. Once the engine dies, turn the key switch to

the OFF position.

•When ready to restart, open the gas valve on the tank and turn the key

switch to the START position. Once the engine has started, move the

bail throttle to the operating position and return to operation.

The Spectre AUTO-Sense is an emissions monitoring device that

monitors the exhaust emissions and will shut the engine down if

the emission levels are too low or too high.

The monitor must receive a signal from the oxygen sensor in order to

function. The oxygen sensor must reach operating temperature before

it will start to send signals to the AUTO-Sense module. This warm-up

period is approximately 3 minutes. After the initial 3 minutes, the

module will start evaluating the signal from the oxygen sensor. If the

module receives an abnormal reading for a period of 1 minute, the

unit will shut down.

If the machine is also allowed to idle for more than 4 minutes, an indicator

light will flash for 1 minute and then the engine will shut down. If this

happens, turn the key to the OFF position for several seconds to clear the

AUTO-Sense module and restart the machine.

OPERATOR’S MANUAL

17

!

SPECTRE

AUTO-Sense

Emissions

Monitoring System

Once the engine has started, advance the bail throttle to operating

position and start the operation. With the engine at full throttle, under load,

the signal from the oxygen sensor should be within the normal operating

ranges for safe operation.

If the engine’s air intake filter needs to be serviced, or an over-filled

propane tank has been installed by mistake, or there is a problem with the

fuel system that causes the oxygen sensor’s signal to be out of range,

AUTO-Sense will shut the unit down after 1 minute. The unit can be re-

started after clearing the module by turning the key switch. If corrections

have not been made to the unit, AUTO-Sense will continue to shut the unit

down until the problem is corrected.

Engines tend to go to a lean burn if allowed to idle for even short periods.

Even at high idle speeds most engines will continue to lean downward. it

is always best to shut the engine off when it is not being used to do work.

Remember, the engine is always creating emissions as long as it is

running.

The best manner to operate the machine is:

With the engine throttle in the SLOW position, turn the key switch to the

START position. Once the engine starts, advance the throttle to full

throttle FAST.

When ready to stop the machine, move the engine throttle to the SLOW

position. If the machine will not be used within 45 seconds, turn the key

switch to the OFF position, or if the machine will not be used within a few

minutes, it is best to turn the gas valve off first and let the engine consume

all fuel that is in the lines. Once the engine dies, turn the key switch to the

OFF position.

When ready to restart, open the gas valve on the tank, put the engine

throttle in the SLOW position and turn the key switch to the START

position. Once the engine has started, move the engine throttle to the

FULL position and return to operation.

The hour meter/tachometer records the number of hours the machine has

been powered ON. The hour meter reading is used to mark the

recommended maintenance intervals. It also displays the engine speed.

The meter displays hours when the machine is turned OFF and the

engine speed when the machine is turned ON.

STEALTH SPECTRE

OPERATOR’S MANUAL

18

!

Hour Meter/

Tachometer

The handle on both the STEALTH and the SPECTRE is designed to be

positioned upright to allow for the machine to be tilted back.

STEALTH SPECTRE

For the STEALTH:

1. Close the valve on the propane tank. Allow the engine to stop and turn

the machine OFF.

2. Remove the propane tank.

3. Loosen the handle pivot knobs so that the handle can slide.

4. Pull the handle out until it stops.

OPERATOR’S MANUAL

19

!

EZ Bak Tilt

Operation

This manual suits for next models

1

Table of contents

Other WerkMaster Floor Machine manuals

Popular Floor Machine manuals by other brands

HOS

HOS Orbot Operation manual

Alto

Alto Clarke Vision 17E Operator's manual

DiamaPro Systems

DiamaPro Systems SVX3-M owner's manual

Minuteman

Minuteman MR1500 Series Parts and instruction manual

Wetrok

Wetrok DISCOMATIC SAMBA XT operating instructions

Nobles

Nobles Speed Scrub 2001 612946 Operator and parts manual