is allowed, in order to restore forward start, disconnect STOP and COM terminal, and then

disconnect FW and COM terminal, reconnect them and forward start is restored. And so on for

backward brake.

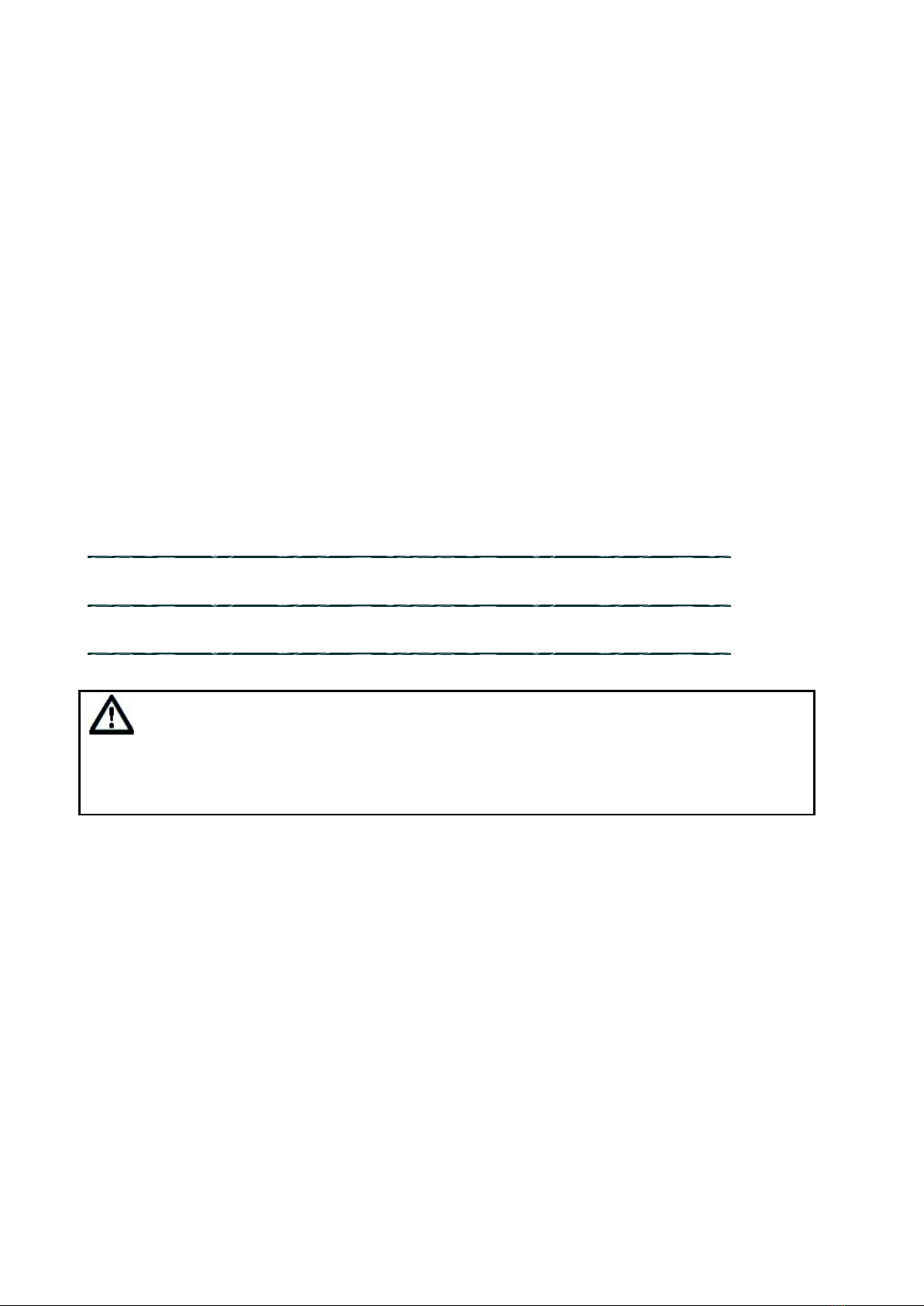

XIII. Motor forward and backward limit:

Forward limit Backward limit

Forward limit: LIMIT FW and COM shall be shorted connected, i.e. forward limit.

Backward limit: LIMIT BW and COM shall be shorted connected, i.e. backward limit.

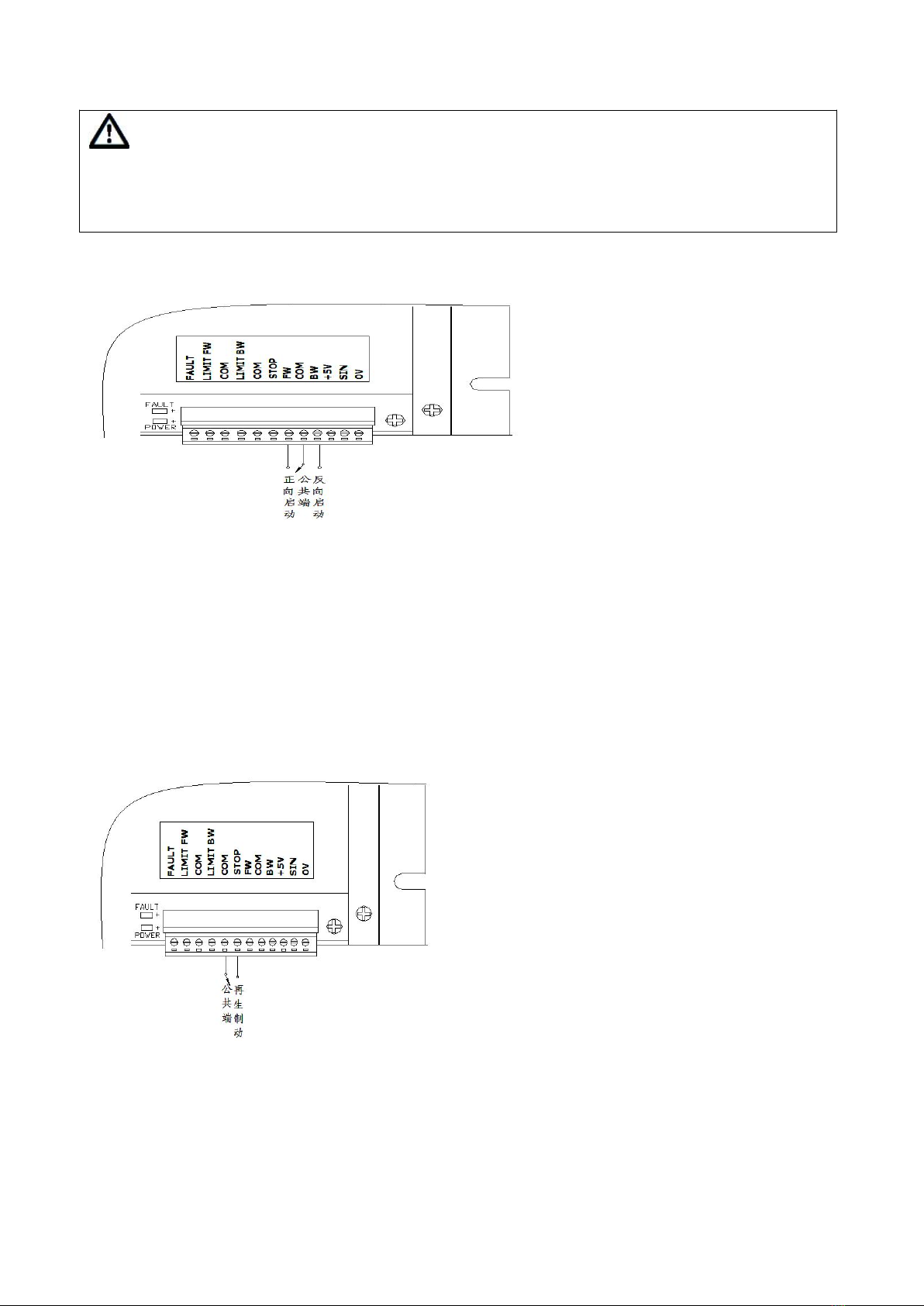

Note: in case of using limit function, need to know the details of logical relationship between

forward & backward start and forward& backward limit.

Control logic:

Firstly, confirm that COM terminal is not shorted connected with LIMIT FW or LIMIT BW, if

required by switch functions, limit direction which is opposite to moving direction shall be selected

for shorted connection.

Back and forth movement of motor:

Supposing that initial position will move forward, firstly, disconnect forward limit and connect

backward limit, and then connect forward start, motor is in direct motion; when it move forward to

certain position, disconnect backward limit, connect forward limit, motor will be immediately

stopped; after this, disconnect forward start, connect backward start, motor is in opposite running,

when it move backward to certain position, disconnect forward limit, connect backward limit, motor

will be immediately stopped. After the completion of above-mentioned actions, a cycle of control

logics has been finished, if repetition is required, above-mentioned control logic need to be

circulated.

XIV. Fault alarm: