Guide & Manual for ROSTOK 3D Printer

Content

1. Product manual................................................................................................................................1

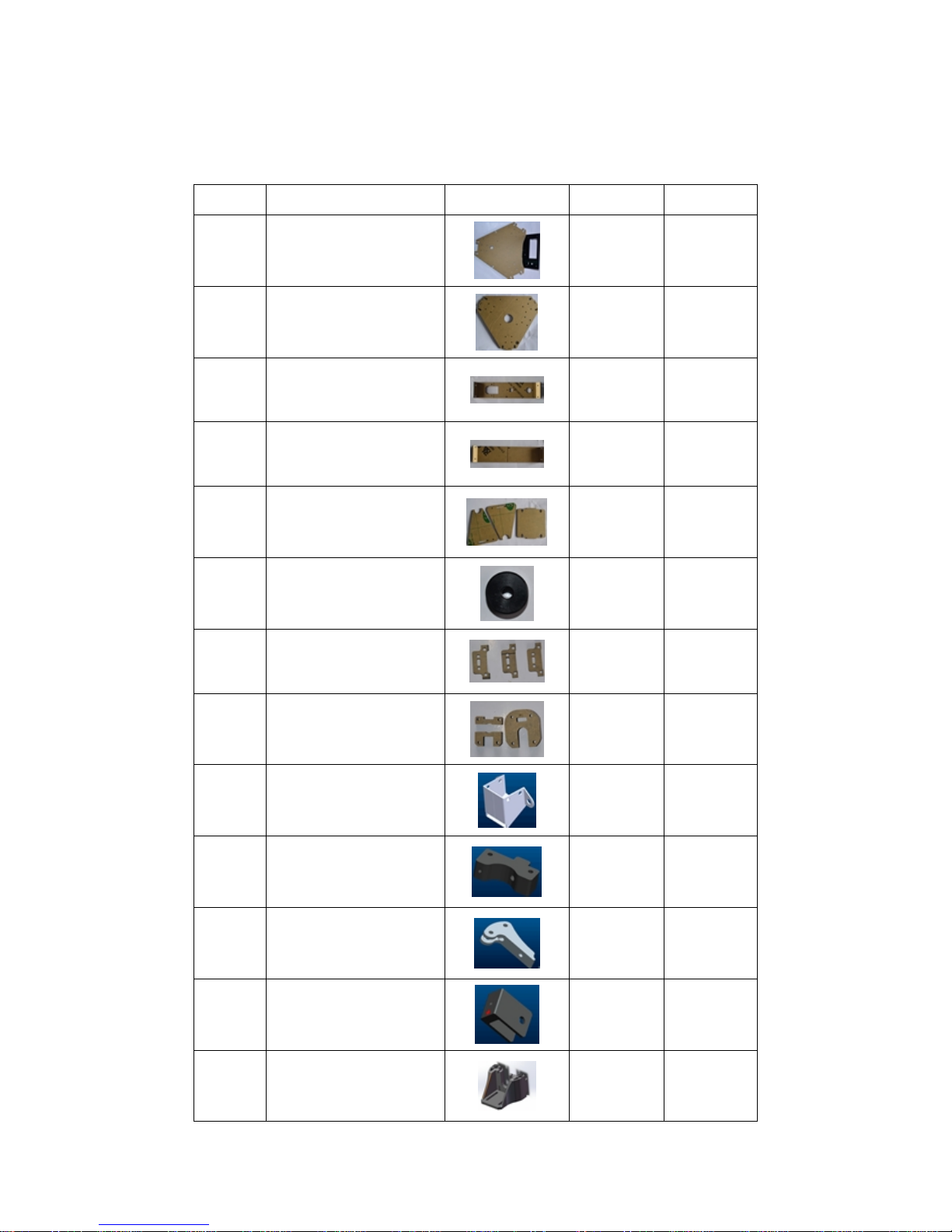

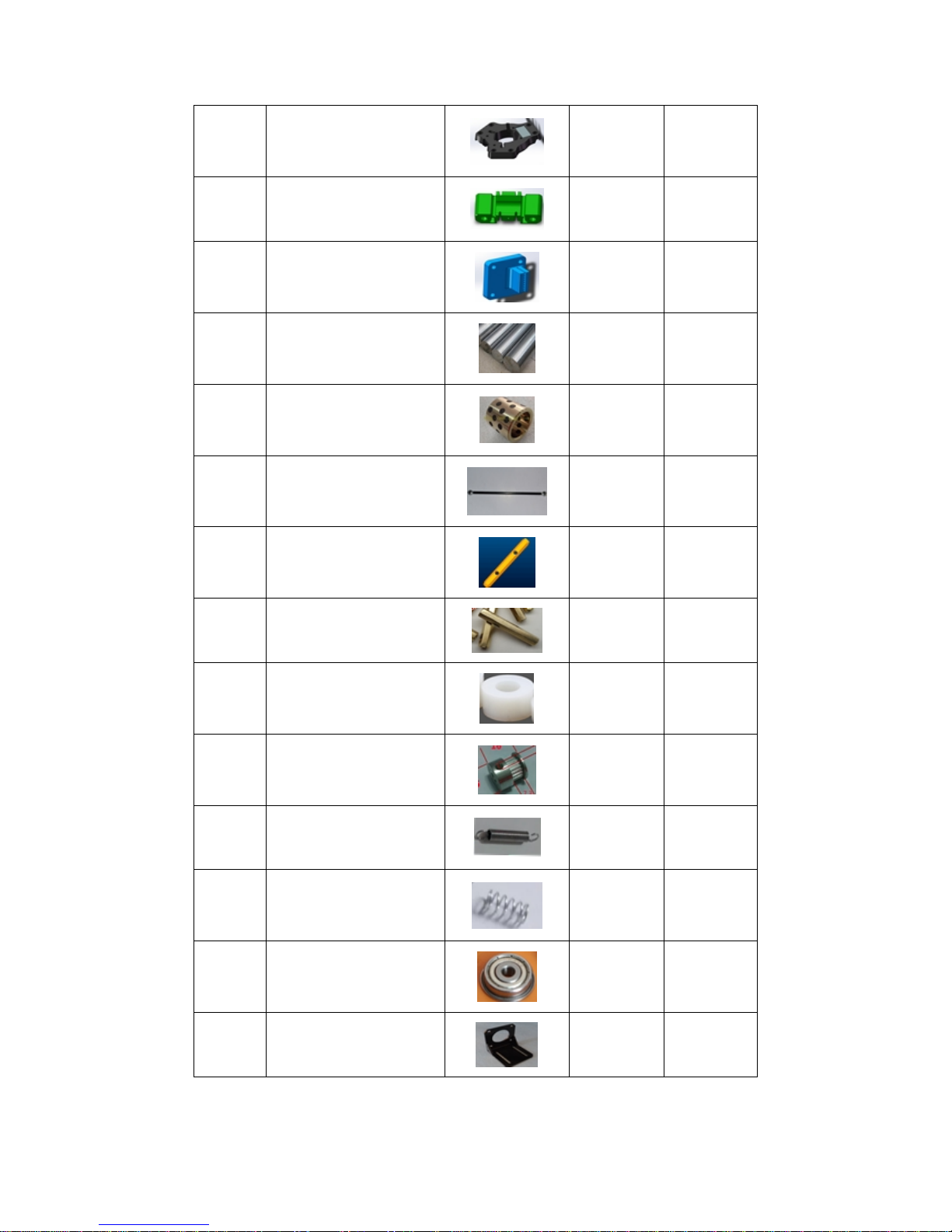

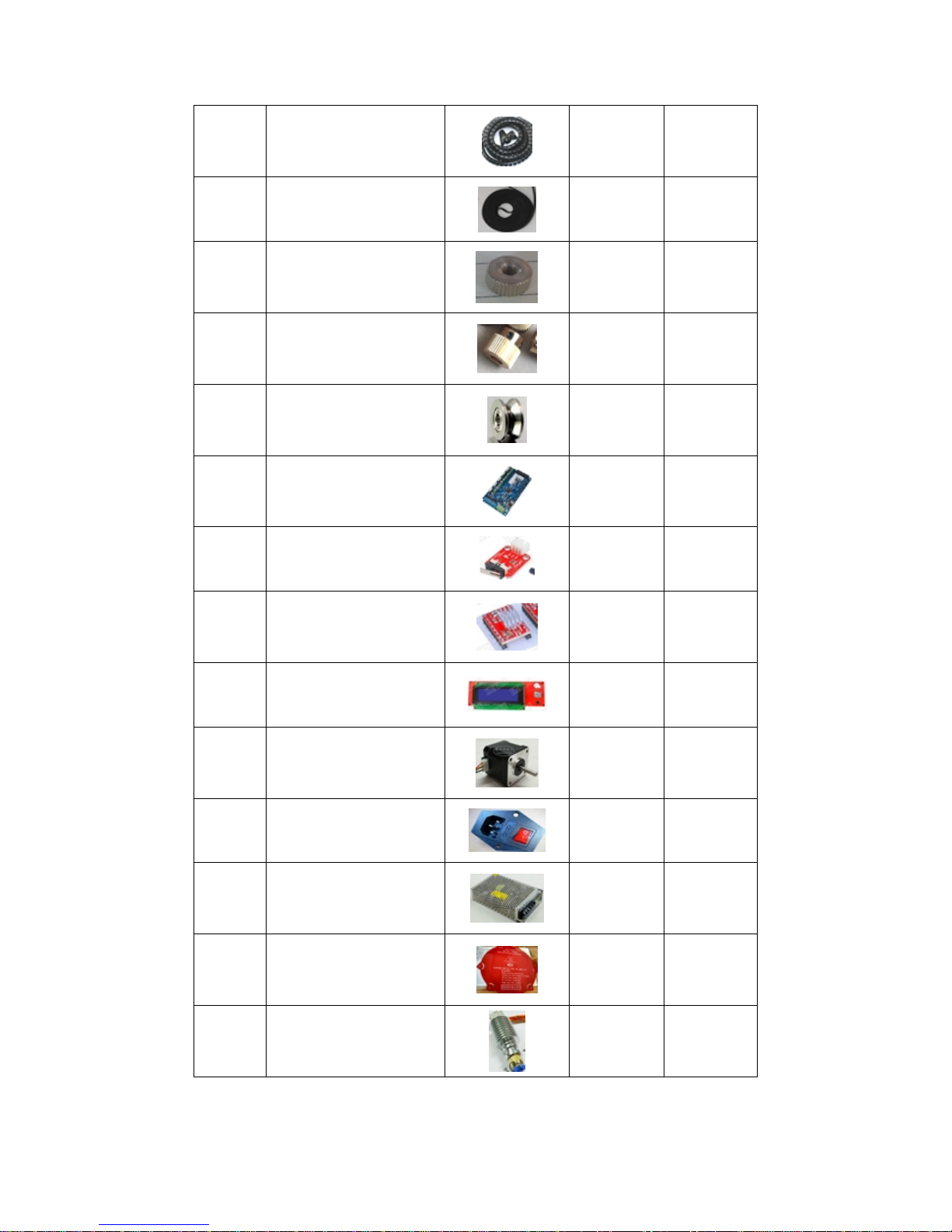

2. BOM................................................................................................................................................4

3. Technical Manual for Installation................................................................................................... 9

I. Installation procedures.............................................................................................................9

1. Installing bottom bracket................................................................................................ 9

2. Installing bottom fixed plate of the frame.................................................................... 10

3. Installing motor............................................................................................................. 12

4. Installing sliding block..................................................................................................14

5. Installing top fixed plate of the frame...........................................................................15

6. Installing power supply.................................................................................................18

7. Installing 3D V1.2 mainboard.......................................................................................19

8. Installing 2004 display.................................................................................................. 21

9. Installing nozzle............................................................................................................ 22

10. Installing hotbed..........................................................................................................23

11. Installing side shield....................................................................................................25

12. Connecting nozzle with sliding block.........................................................................26

13. Installing collision board.............................................................................................27

14. Installing synchronous belt and its regulator.............................................................. 29

15. Installing extruder....................................................................................................... 30

16. Installing material rack................................................................................................32

II. Connecting components:...................................................................................................... 34

4. Connection diagram...................................................................................................................... 37

5. ROSTOK Manual Leveling.......................................................................................................... 37

6. Height adjustment for 3D printer nozzle and hotbed....................................................................46

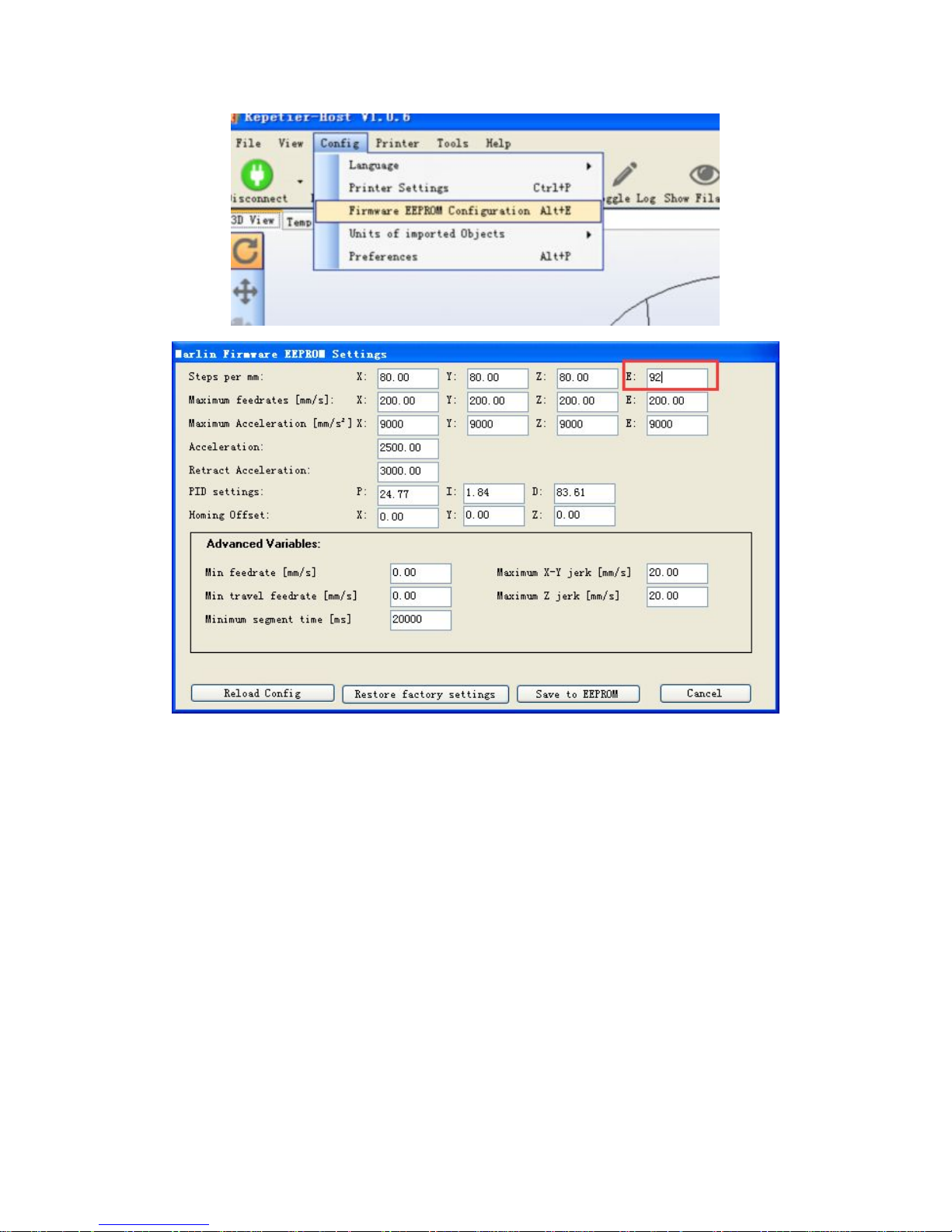

7. Easy use of Repetier-Host software.............................................................................................. 49

1. Repetier-Host overview........................................................................................................ 49

2. slicing.................................................................................................................................... 56

1)parameter setup for Slic3r...........................................................................................56

2)CuraEngine Settings....................................................................................................66

8. G-code........................................................................................................................................... 72

Content...................................................................................................................................... 73

Introduction............................................................................................................................... 77

RepRap G-code fields............................................................................................................... 78

Comments..................................................................................................................................79

9. LCD Menu details....................................................................................................................... 101