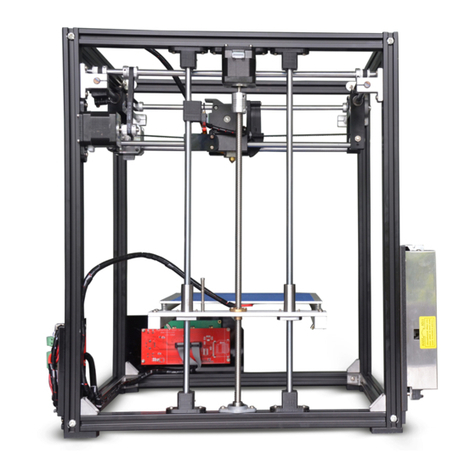

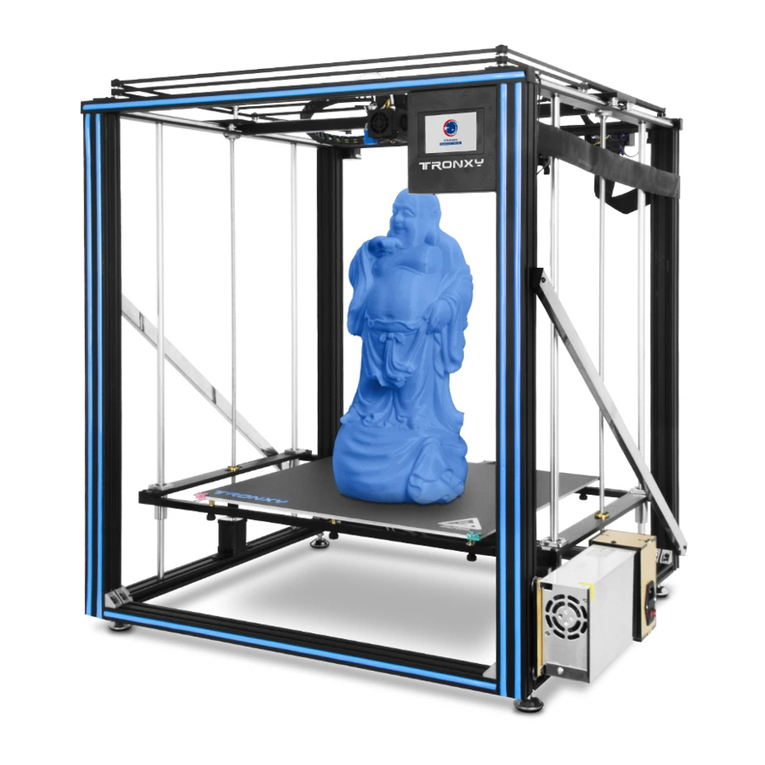

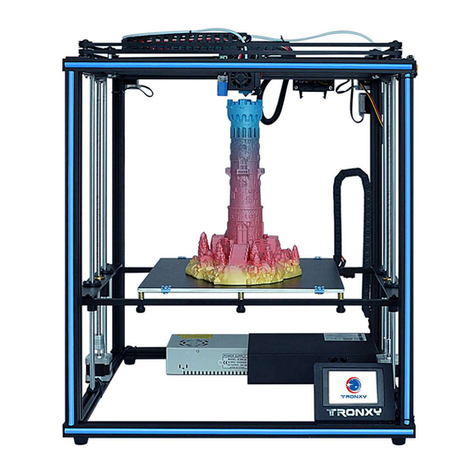

TRONXY X5SA-400-2E User manual

Table of contents

Other TRONXY 3D Printer manuals

TRONXY

TRONXY P802M User manual

TRONXY

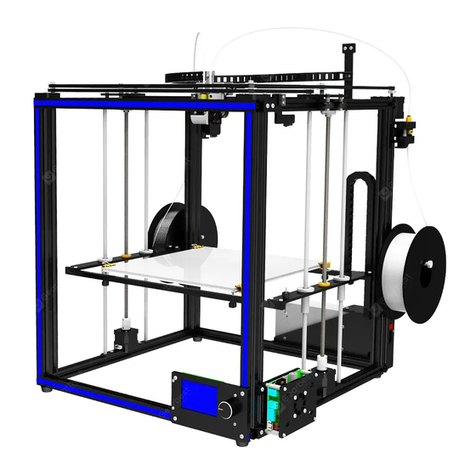

TRONXY X5 User manual

TRONXY

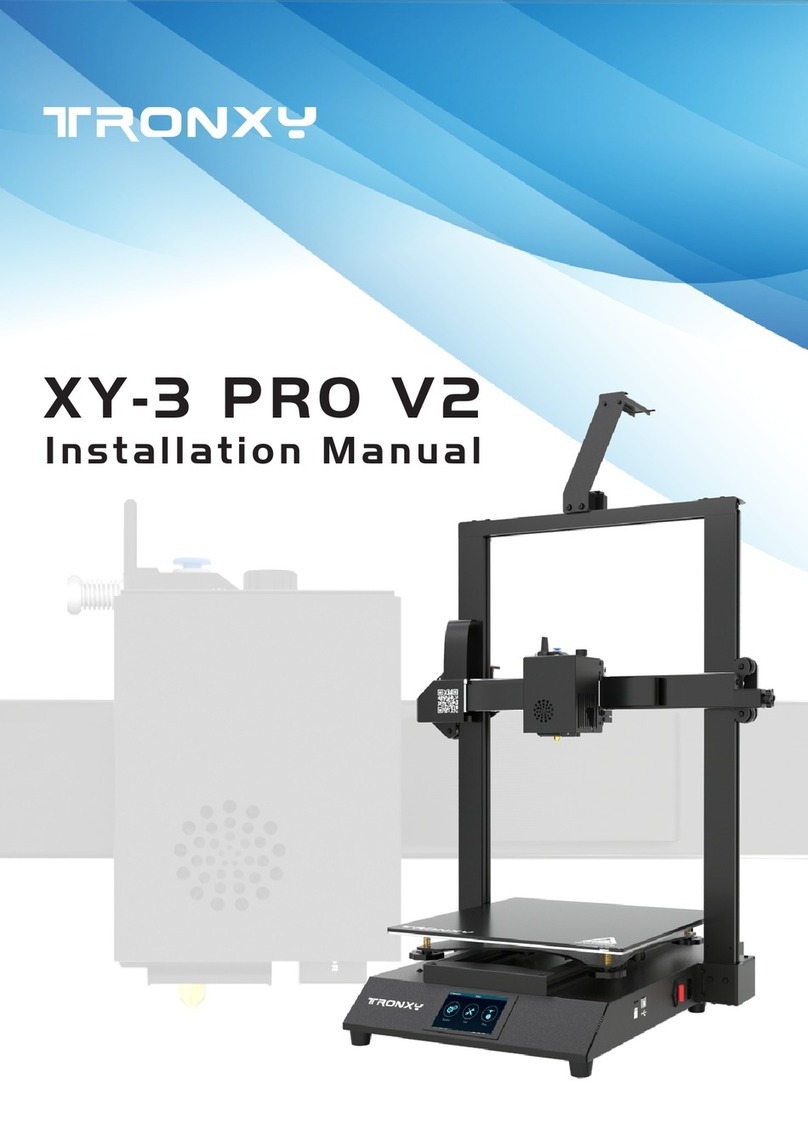

TRONXY XY-3 PRO V2 User manual

TRONXY

TRONXY XY-2 PRO User manual

TRONXY

TRONXY X5SA-400-PRO User manual

TRONXY

TRONXY X5S 2E User manual

TRONXY

TRONXY X5S User manual

TRONXY

TRONXY XY-2 User manual

TRONXY

TRONXY VEHO600 User manual

TRONXY

TRONXY VEHO 600-2E User manual

TRONXY

TRONXY XY-2 PRO User manual

TRONXY

TRONXY X3A User manual

TRONXY

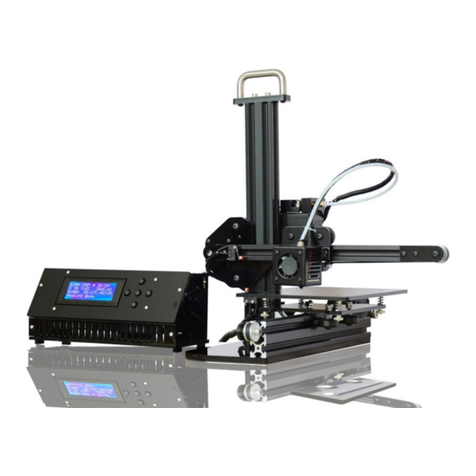

TRONXY X1 User manual

TRONXY

TRONXY X5SA-500-PRO User manual

TRONXY

TRONXY X5SA User manual

TRONXY

TRONXY X6-2E User manual

TRONXY

TRONXY X3A User manual

TRONXY

TRONXY Ultrabot User manual

TRONXY

TRONXY D01 User manual

TRONXY

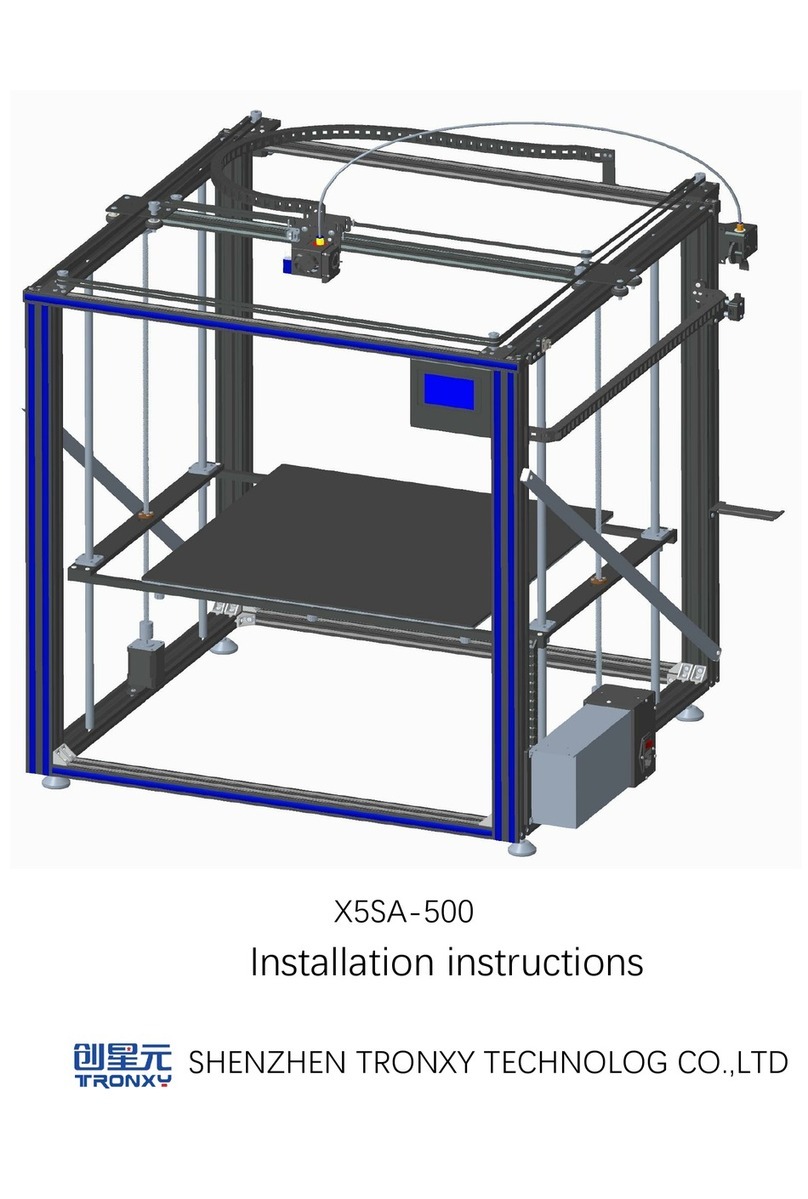

TRONXY X5SA-500 User manual

Popular 3D Printer manuals by other brands

Ultimaker

Ultimaker Ultimaker S5 Pro Bundle Installation and user manual

Ouring

Ouring 3DTALK Future user manual

Elegoo

Elegoo NEPTUNE 4 PRO user manual

Axis Technology

Axis Technology PackshotCreator 3D user guide

WhittleCNC

WhittleCNC WhittleCNC Assembly instructions

WANHAO

WANHAO DUPLICATOR 9 instruction manual