Keysight Technologies PD1500A User guide

Keysight PD1500A

Double-Pulse Test Rack and

Safety Enclosure

Provides detailed information to install the Double-

Pulse Test Rack and Safety Enclosure at a customer

site. The Rack and Safety Enclosure is used with the

PD1500A Dynamic Power Device Analyzer/Double-

Pulse Tester.

System Installation

Guide

Notices

© Keysight Technologies, Inc. 2020-2022

No part of this manual may be repro-

duced in any form or by any means

(including electronic storage and retrieval

or translation into a foreign language)

without prior agreement and written con-

sent from Keysight Technologies, Inc. as

governed by United States and interna-

tional copyright laws.

Manual Part Number

PD1500-90002

Edition

Fourth Edition, March 2022

Published by

Keysight Technologies, Inc.

900 S. Taft Ave.

Loveland, CO 80537 USA

Sales and Technical Support

To contact Keysight for sales and techni-

cal support, refer to the support links on

the following Keysight websites:

www.keysight.com/find/PD1500A

(product-specific information and sup-

port, software and documentation

updates)

www.keysight.com/find/assist (world-

wide contact information for repair and

service)

Declaration of Conformity

Declarations of Conformity for this prod-

uct and for other Keysight products may

be downloaded from the Web. Go to

http://keysight.com/go/conformity and

click on “Declarations of Conformity.” You

can then search by product number to

find the latest Declaration of Conformity.

Technology Licenses

The hardware and/or software described

in this document are furnished under a

license and may be used or copied only in

accordance with the terms of such

license.

Warranty

THE MATERIAL CONTAINED IN THIS

DOCUMENT IS PROVIDED “AS IS,” AND

IS SUBJECT TO BEING CHANGED,

WITHOUT NOTICE, IN FUTURE EDI-

TIONS. FURTHER, TO THE MAXIMUM

EXTENT PERMITTED BY APPLICABLE

LAW, KEYSIGHT DISCLAIMS ALL WAR-

RANTIES, EITHER EXPRESS OR IMPLIED,

WITH REGARD TO THIS MANUAL AND

ANY INFORMATION CONTAINED

HEREIN, INCLUDING BUT NOT LIMITED

TO THE IMPLIED WARRANTIES OF MER-

CHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. KEYSIGHT

SHALL NOT BE LIABLE FOR ERRORS OR

FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES IN CONNECTION WITH THE

FURNISHING, USE, OR PERFORMANCE

OF THIS DOCUMENT OR OF ANY INFOR-

MATION CONTAINED HEREIN. SHOULD

KEYSIGHT AND THE USER HAVE A SEP-

ARATE WRITTEN AGREEMENT WITH

WARRANTY TERMS COVERING THE

MATERIAL IN THIS DOCUMENT THAT

CONFLICT WITH THESE TERMS, THE

WARRANTY TERMS IN THE SEPARATE

AGREEMENT SHALL CONTROL.

Keysight Technologies does not warrant

third-party system-level (combination of

chassis, controllers, modules, etc.) per-

formance, safety, or regulatory compli-

ance unless specifically stated.

DFARS/Restricted Rights

Notices

If software is for use in the performance

of a U.S. Government prime contract or

subcontract, Software is delivered and

licensed as “Commercial computer soft-

ware” as defined in DFAR 252.227-7014

(June 1995), or as a “commercial item” as

defined in FAR 2.101(a) or as “Restricted

computer software” as defined in FAR

52.227-19 (June 1987) or any equivalent

agency regulation or contract clause.

Use, duplication or disclosure of Software

is subject to Keysight Technologies’ stan-

dard commercial license terms, and non-

DOD Departments and Agencies of the

U.S. Government will receive no greater

than Restricted Rights as defined in FAR

52.227-19(c)(1-2) (June 1987). U.S. Gov-

ernment users will receive no greater

than Limited Rights as defined in FAR

52.227-14 (June 1987) or DFAR 252.227-

7015 (b)(2) (November 1995), as applica-

ble in any technical data.

Safety Information

The following general safety precau-

tions must be observed during all

phases of operation of these instru-

ments. Failure to comply with these

precautions or with specific warnings

or operating instructions in the product

manuals violates safety standards of

design, manufacture, and intended use

of the instruments. Keysight Technolo-

gies assumes no liability for the cus-

tomer's failure to comply with these

requirements.

General

Do not use these instruments in any manner

not specified by the manufacturer. The pro-

tective features of these instruments must

not be impaired if it is used in a manner

specified in the operation instructions.

Before Applying Power

Verify that all safety precautions are taken.

Make all connections to the instruments

before applying power. Note the external

markings described under “Safety Symbols”.

Ground the Instrument

Keysight instruments are provided with

a grounding-type power plug. The

instruments must be connected to an

electrical ground to minimize shock

hazard. The ground pin must be firmly

connected to an electrical ground

(safety ground) terminal at the power

outlet. Any interruption of the protec-

tive (grounding) conductor or discon-

nection of the protective earth terminal

will cause a potential shock hazard

that could result in personal injury.

Unless otherwise noted in the specifi-

cations, these instruments or system is

intended for indoor use in an installa-

tion category II, pollution degree 2

environment per IEC 61010-1 and 664

respectively. They are designed to

operate at a maximum relative humid-

ity of 50% to 80% at 30 °C or less (non-

condensing). These instruments or sys-

tem are designed to operate at alti-

tudes up to 3000 meters, and at

temperatures between 20 and 30 °C.

Do Not Operate in an Explosive Atmo-

sphere Do not operate in the presence

of flammable gases or fumes.

Do Not Operate Near Flammable

Liquids

Do not operate the instruments in the

presence of flammable liquids or near

containers of such liquids.

Cleaning

Clean the outside of the Keysight

instruments with a soft, lint-free,

slightly dampened cloth. Do not use

detergent or chemical solvents.

Do Not Remove Instrument Cover

Only qualified, service-trained person-

nel who are aware of the hazards

involved should remove instrument

covers. Always disconnect the power

cable and any external circuits before

removing the instrument cover.

Keep away from live circuits

Operating personnel must not remove

equipment covers or shields. Proce-

dures involving the removal of covers

and shields are for use by service-

trained personnel only. Under certain

conditions, dangerous voltages may

exist even with the equipment

switched off. To avoid dangerous elec-

trical shock, DO NOT perform proce-

dures involving cover or shield removal

unless you are qualified to do so.

DO NOT operate damaged

equipment

Whenever it is possible that the safety

protection features built into these

instruments have been impaired, either

through physical damage, excessive

moisture, or any other reason,

REMOVE POWER and do not use the

instrument until safe operation can be

verified by service-trained personnel. If

necessary, return the product to a Key-

sight Technologies Sales and Service

Office for service and repair to ensure

the safety features are maintained.

DO NOT block the primary

disconnect

The primary disconnect device is the

appliance connector/power cord when

an instrument used by itself, but when

installed into a rack or system the dis-

connect may be impaired and must be

considered part of the installation.

Do Not Modify the Instrument

Do not install substitute parts or per-

form any unauthorized modification to

the product. Return the product to a

Keysight Sales and Service Office to

ensure that safety features are main-

tained.

In Case of Damage

Instruments that appear damaged or

defective should be made inoperative

and secured against unintended oper-

ation until they can be repaired by

qualified service personnel.

Measurement Limits

The Truevolt Series DMMs provide pro-

tection circuitry to prevent damage to

the instrument and to protect against

the danger of electric shock, provided

the Measurement Limits are not

exceeded. To ensure safe operation of

the instrument, do not exceed the

Measurement Limits shown on the

front and rear panel.

The DMMs comply with EN/IEC 61326-

2-1, for sensitive test and measure-

ment equipment.

When subjected to transient radiated

and/or conducted electromagnetic

phenomena, the DMMs may have tem-

porary loss of function or performance

which is self-recovering. Recovery may

take longer than 10 seconds.

When subjected to continuously pres-

ent electromagnetic phenomena, some

degradation of performance may

occur.

ii

Safety and Regulatory Symbols

A CAUTION denotes a hazard. It

calls attention to an operating pro-

cedure or practice that, if not cor-

rectly performed or adhered to,

could result in damage to the

product or loss of important data.

Do not proceed beyond a CAUTION

notice until the indicated condi-

tions are fully understood and met.

A WARNING denotes a hazard. It

calls attention to an operating pro-

cedure or practice, that, if not cor-

rectly performed or adhered to,

could result in personal injury or

death. Do not proceed beyond a

WARNING notice until the indi-

cated conditions are fully under-

stood and met.

Products display the following:

The CE marking is a registered trade-

mark of the European Community (if

accompanied by a year, it is the year

when the design was proven). It indi-

cates that the product complies with

all relevant EU directives.

The Regulatory Compliance Mark

(RCM) is a registered trademark of the

Australian Communications and Media

Authority.

The CSA mark is a registered trade-

mark of the Canadian Standards Asso-

ciation and indicates compliance to

the standards laid out by them. Refer

to the product Declaration of Confor-

mity for details.

This symbol represents the time period

during which no hazardous or toxic

substance elements are expected to

leak or deteriorate during normal use.

Forty years is the expected useful life

of this product.

Universal recycling symbol. This sym-

bol indicates compliance with the

China standard GB 18455-2001 as

required by the China RoHS regula-

tions for paper/fiberboard packaging.

South Korean Certification (KC) mark.

It includes the marking’s identifier

code.

Refer to manual for

additional safety

information.

Earth Ground.

Chassis Ground.

Alternating Current (AC).

Direct Current (DC).

Standby Power. Unit is not

completely disconnected

from AC mains when power

switch is in standby position

Indicates that antistatic

precautions should be

taken.

DANGER:

High Voltage

Hot Surface; DO NOT

Touch!

R-R-Kst-SP19629

iii

Waste Electrical and

Electronic

Equipment (WEEE)

The crossed-out wheeled bin symbol

indicates that separate collection for

Waste Electric And Electronic Equip-

ment (WEEE) is required, as obligated

by the EU DIRECTIVE and other

National legislation.

Please refer to keysight.com/go/take-

back to understand your trade-in

options with Keysight in addition to

takeback instructions.

Traditional Chinese

根據歐盟指令和其他國家的法律規定,

帶有X標誌的帶輪垃圾桶圖案,表示

該產品屬於需要進行單獨回收的電子

電器產品。

請參考 keysight.com/go/takeback ,

了解產品回收說明以及Keysight的以

舊換新方式。

Simplified Chinese

根据欧盟指令和其他国家的法律规定,

带有X标志的带轮垃圾桶图案,表示

该产品属于需要进行单独回收的电子

电器产品。

请参考 keysight.com/go/takeback ,

了解产品回收说明以及Keysight的以

旧换新方式。

Japanese

車輪付きゴミ箱に×マークは、EU

DIRECTIVEやその他の国の法律で義

務付けられている廃電気・電子機器

(WEEE)の分別回収が必要であるこ

とを示しています。

keysight.com/go/takeback では、製

品のテイクバック方法に加えて、

Keysight の下取りオプションに

ついてもご紹介しています。

Korean

바퀴달린 쓰레기통의 X 표시는 EU 지

침 및 기타 국가 법률에 따라 전기 및

전자 장비 폐기물(WEEE)에 대한 별도

수거가 필요함을 나타냅니다.

제품 회수 지침과 함께 Keysight를 통

한 보상 판매 옵션을 이해하려면 key-

sight.com/go/takeback 을 참조하십시

오.

German

Das Symbol der durchgestrichenen

Mülltonne auf Rädern weist darauf hin,

dass eine getrennte Sammlung von

Elektro- und Elektronik-Altgeräten

(WEEE) gemäß der EU-RICHTLINIE

und anderer nationaler Gesetze

erforderlich ist.

Bitte informieren Sie sich unter key-

sight.com/go/takeback über Ihre

Rücknahmeoptionen bei Keysight

sowie über die Anweisungen zur Pro-

duktrücknahme.

French

Le pictogramme de la poubelle barrée

indique que la collecte séparée des

déchets d'équipements électriques et

électroniques (DEEE) est requise,

comme l'obligent la directive

européenne et d'autres législations

nationales.

Veuillez vous référer à keysight.com/

go/takeback pour obtenir les options

d’échange Keysight en plus des

instructions de reprise de produit.

Italian

Il simbolo del bidone barrato indica

che è richiesta la raccolta separata dei

rifiuti di apparecchiature elettriche ed

elettroniche (RAEE), come previsto

dalla DIRETTIVA UE e da altre leg-

islazioni nazionali.

Si prega di fare riferimento al sito key-

sight.com/go/takeback per compren-

dere le opzioni di Commercializzazione

con Keysight oltre alle istruzioni per il

ritiro del prodotto.

Spanish

El símbolo del contenedor de basura

tachado indica la obligación de rec-

ogida selectiva de los residuos de

aparatos eléctricos y electrónicos

(RAEE), tal y como lo establece la

DIRECTIVA de la UE y otras legisla-

ciones nacionales.

Acceda a nuestra página key-

sight.com/go/takeback para obtener

información sobre las opciones de

recuperación que ofrece Keysight, y

las instrucciones de recuperación del

producto.

Portuguese

O símbolo da lata de lixo riscada indica

que a necessidade da coleta seletiva

dos resíduos de equipamentos eléctri-

cos e electrónicos (REEE) é obrigatória,

em consonância com a DIRETIVA da

União Europeia (WEEE) e outras legis-

lações nacionais.

Consulte keysight.com/go/takeback

para verificar suas opções de “trade in”

com o escritório Keysight local, ou

para receber as instruções de recicla-

gem do produto.

Russian

Символ перечеркнутого мусорного

контейнера на колесиках указывает

на необходимость раздельного

сбора отходов электрического и

электронного оборудования

(WEEE) в соответствии с

требованиями ДИРЕКТИВЫ ЕС и

других национальных

законодательств.

Пожалуйста, обратитесь к сайту

keysight.com/go/takeback , чтобы

узнать о возможностях торговли с

компанией Keysight, а также об

инструкциях по возврату

продукции.

iv

v

WARNING

HIGH VOLTAGE

is used in the operation of this equipment.

LETHAL VOLTAGE on CONTACT

may be present at measurement terminals if you fail to implement all safety precautions.

• When the RED light on the light tower is on inside the Double-Pulse Test Rack and Safety

Enclosure, lethal voltage (±1000 V dc/pulse) may appear at measurement terminals.

• Never attempt to defeat the safety interlock function of the Safety Hood.

• Do not operate the system unless another person is around the work space who is familiar with

system operation and hazards or administering first aid.

• Potential voltages less than ±500 V may cause death under certain conditions. Therefore,

adequate preventive measures must be taken at all times!

Safety Summary

The following general safety precautions must be observed during all phases of operation, service, and

repair of this system. Failure to comply with these precautions or with specific warnings elsewhere in

this manual may impair the protections provided by the system. In addition, it violates safety standards

of design, manufacture, and intended use of the system. Keysight Technologies assumes no liability for

customer’s failure to comply with these requirements.

Product manuals are available on the Web. Go to www.keysight.com/find/PD1500A for all

documentation.

Hazardous voltage: System maximum output voltage may appear at the

measurement terminals inside the Safety Hood. Never attempt to bypass the safety

interlock and features of the PD1500A Double-Pulse Test System Rack and Safety

Enclosure. To avoid contact with extremely high voltages, the rack cabinet must be

operated with all side, front, and rear panels in place and the Safety Hood must

remain closed. There are no user-serviceable parts inside.

Do not intentionally modify the interlock function of the Safety Hood. While

the high voltage indicator is lit, dangerous voltage or residual charge may

appear on the measurement terminals.

Some of the material in the safety enclosure can generate static electricity. Take

care if you are using ESD sensitive devices in its vicinity.

vi

DANGEROUS PROCEDURE WARNINGS

• Warnings shall be complied. Procedures throughout in this manual prevent you from potential

hazardous situations. The instructions contained in the warnings must be followed.

BEFORE APPLYING POWER

• Verify that all safety precautions are taken. Make all connections to the system before applying

power. Note the system's external markings described under “Safety and Regulatory Symbols”.

GROUND THE RACK

• This is Safety Class I system. To minimize shock hazard, the Rack and Safety Enclosure must be

connected to an electrical ground. The power terminal and the power cable must meet

International Electrotechnical Commission (IEC) safety standards.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

• Do not operate the system in the presence of flammable gases or fumes. Operation of any

electrical instrument in such an environment constitutes a definite safety hazard.

DO NOT REMOVE COVERS

• No operator serviceable parts inside. Refer servicing to qualified personnel. To prevent

electrical shock do not remove covers.

IN CASE OF DAMAGE

• Instruments, probes or cables that appear damaged or defective should be made inoperative

and secured against unintended operation until they can be repaired by qualified service

personnel. Return the product to a Keysight Technologies sales or service office for service and

repair to ensure that safety features are maintained.

USE ONLY THE SPECIFIC ACCESSORIES

• Specified accessories satisfy the requirements for specific characteristics for using the

instruments and the Rack and Safety Enclosure.

CLEANING

• Disconnect the power from the rack before cleaning the Rack and Safety Enclosure. Use only a

damp cloth to clean the surfaces of the Rack and Safety Enclosure.

Do not use this system in any manner not specified by the manufacturer. The

protective features of this system may be impaired if it is used in a manner not

specified in the operation instructions. This system is an INDOOR USE product only.

This system complies with INSTALLATION CATEGORY II for mains input and

INSTALLATION CATEGORY I for measurement input terminals, and POLLUTION

DEGREE 2 defined in IEC 61010-1.

If an system is marked CAT I (IEC Measurement Category I), or it is not marked with a

measurement category, its measurement terminals must not be connected to line-

voltage mains.

Safety of any system incorporating the equipment is the responsibility of the

assembler of the system.

Keysight Double-Pulse Test System Installation Guide vii

1 Site Preparation

Customer Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Rack and Safety Enclosure Dimensions and Weight . . . . . . . . . . . . . . . . . . 16

Tools Supplied for Installation and Instrument Removal . . . . . . . . . . . . . . . 16

Double-Pulse Test Rack and Safety Enclosure Location . . . . . . . . . . . . . . . . . 17

Electrical and Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Connect the DPT Rack and Safety Enclosure to AC Mains . . . . . . . . . . . . . 18

AC Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Mains Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Optional Safety Ground Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Receiving The Rack and Safety Enclosure and Test Instruments . . . . . . . . . . . 20

Moving the Rack and Safety Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Inventory the Shipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Host Computer System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Static-safe Handling Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Simplified System Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2 Uncrate the Rack and Safety Enclosure

Uncrate the Rack and Safety Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Moving the Rack and Safety Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

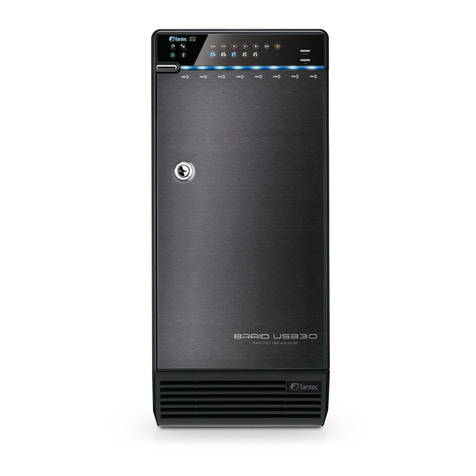

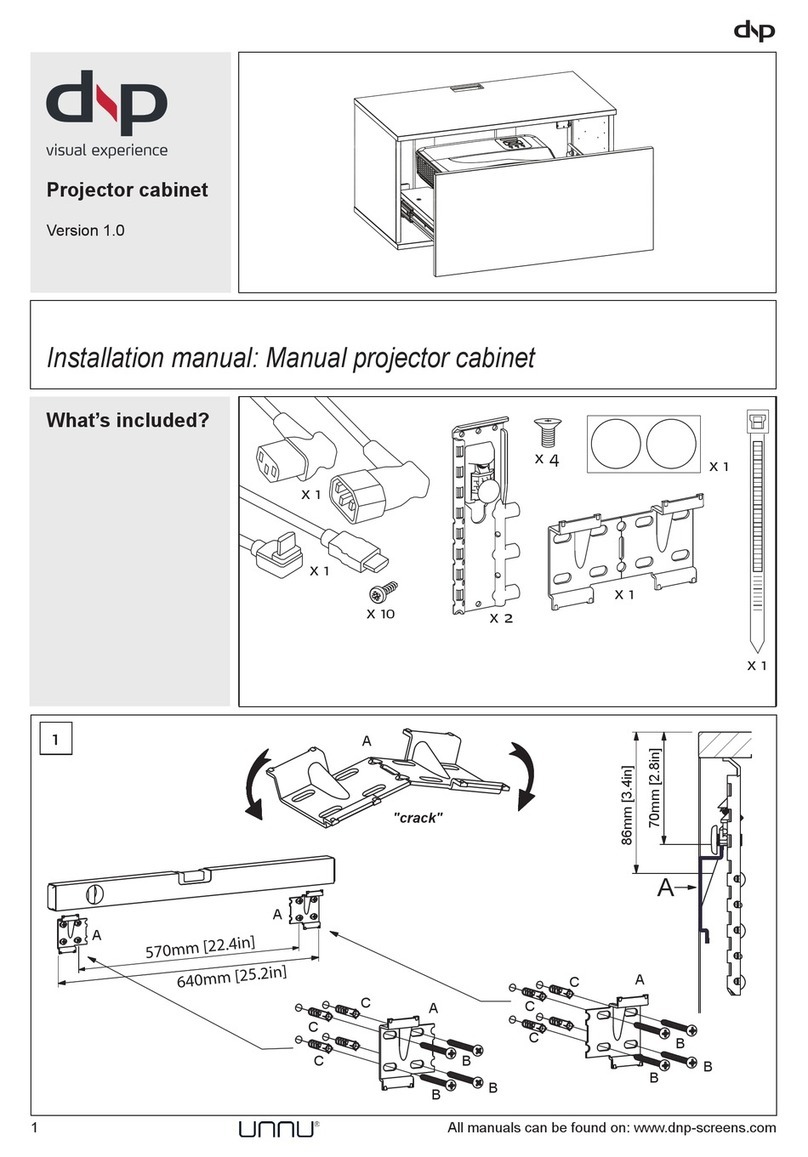

Rack and Safety Enclosure System Hardware Components. . . . . . . . . . . . . . . 30

Re-crating the Rack and Safety Enclosure for Shipping. . . . . . . . . . . . . . . . . . 31

3 Install Oscilloscope in Safety Enclosure Hood

Prepare the Rack and Safety Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Install Oscilloscope Inside the Safety Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Connect LAN, Power, and Trigger Cables to the Oscilloscope. . . . . . . . . . . . . 35

Connect Probes to DSOS104A or MXR108A Oscilloscope . . . . . . . . . . . . . . . . 37

Connect Probes to the Double-Pulse Test Modules. . . . . . . . . . . . . . . . . . . 40

Contents

viii Keysight Double-Pulse Test System Installation Guide

Using the N2787A 3D Probe Positioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4 Install Test Fixture in the Safety Enclosure Hood

Placing the Test Fixture in the Safety Enclosure Hood . . . . . . . . . . . . . . . . . . . 46

Connections on Back of Test Fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Connections on Front of Test Fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Connect the Waveform Generator to the DPT Test Fixture . . . . . . . . . . . . . 48

Optional Low-Side Device Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Second Thermocouple Jack on Test Fixture . . . . . . . . . . . . . . . . . . . . . . 49

Using the Low-Side Device Heater and Thermocouple. . . . . . . . . . . . . . . . 49

Adding Kapton (polyimide) Tape to TO-247-3 and -4 Devices . . . . . . . . . . 51

Device Heater Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Configuring Temperature Control Settings (Hardware Configuration) . 53

Mounting the Coaxial Shunt Resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Identify Test Fixture Firmware Version. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5 Turn-on and Software Installation

Step 1: Connect LAN and Power Cable to Rack . . . . . . . . . . . . . . . . . . . . . . . . 60

Double-Pulse Test System Turn-On and Turn-Off . . . . . . . . . . . . . . . . . . . . 60

Turning the System Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Light Tower Inside the Safety Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Emergency Off Functionality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Step 2: Install System Software on Host PC . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Install IO Libraries Suite on Host PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Download PD1000A System Control Software . . . . . . . . . . . . . . . . . . . . . . 62

Software Licensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Step 3: Set Oscilloscope VISA Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Instrument Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Set AC Line Frequency and Date/Time on the B2902 SMU . . . . . . . . . . . . 65

More about IP Addresses and Dot Notation. . . . . . . . . . . . . . . . . . . . . . . . . 65

Step 4: Obtain and Install Coaxial Shunt Resistor De-Embedding File . . . . . . 66

Verify D9020ASIA License on the Oscilloscope . . . . . . . . . . . . . . . . . . . . . . 66

Annual Characterization of the Coaxial Shunt . . . . . . . . . . . . . . . . . . . . . . . 67

Obtain the Shunt De-embedding file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Install the De-Embedding Transfer File on the Oscilloscope. . . . . . . . . . . . 68

6 PD1500A Double-Pulse Test Si/SiC AutoCalibration

Initiate Calibration & Compensation Procedures . . . . . . . . . . . . . . . . . . . . . 70

Oscilloscope Probe Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Keysight Double-Pulse Test System Installation Guide ix

Low Frequency Compensation for the 10076C and N2873A Probes . . . . . 71

Offset Compensation for the N2819A Differential Probe. . . . . . . . . . . . . . . 72

Si/SiC System Calibration Procedure (Autocal) . . . . . . . . . . . . . . . . . . . . . . . . 74

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

±28 V Gate Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Module Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Gate Voltage Calibration – VGS/VGE Probe: Standard Gate Drive Modules 76

Gate Voltage Calibration – VGS/VGE Probe: ±28 V Gate Drive Modules . . . 77

Gate Voltage Source Calibration – VGS/VGE Output: Standard Gate Drive

Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Gate Voltage Source Calibration – VGS/VGE Output: ±28 V Gate Drive

Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Gate Current Calibration – IG Probe: Standard Gate Drive Modules. . . . . . 80

Gate Current Calibration – IG Probe: ±28 V Gate Drive Modules . . . . . . . . 81

Gate On-Resistance Calibration – RG Value: Standard Gate Drive Modules82

Gate On-Resistance Calibration – RG Value: ±28 V Gate Drive Modules . . 83

Gate Off-Resistance Calibration – RG Value: ±28 V Gate Drive Modules

(Split-Path RG,OFF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

High Voltage Probe Calibration – VDS/VCE Probe . . . . . . . . . . . . . . . . . . . . 85

Clamp Circuit Probe Calibration – VCLAMP Probe . . . . . . . . . . . . . . . . . . . . 86

PD1000-60002 Protection Probe Calibration – ID/IC from Shunt . . . . . . . . 87

Oscilloscope Probe Deskew . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Connect Probes to Deskew Fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Initializing PD1000-66848 and -66849 Modules for Calibration . . . . . . . . 90

Initialize New Data EEPROMs for Split-Path Gate Drive Module. . . . . . 91

EEPROM Values for Split-Path Gate Drive Modules . . . . . . . . . . . . . . . . . . 94

Coaxial Shunt Resistor Characterization . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Install the De-Embedding Transfer File on the DSOS104 Oscilloscope 95

A Simplified System Diagrams and Schematics

Connect Probes to DSOS104A or MXR108A Oscilloscope. . . . . . . . . . . . . . . 100

Simplified DPT Test Schematics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

B SMA Connectors

Final Connection Using a Torque Wrench . . . . . . . . . . . . . . . . . . . . . . . . . 106

Separating Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Inspect and Clean Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Connector Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

x Keysight Double-Pulse Test System Installation Guide

Double-Pulse Test System

Installation Guide

15

1Site Preparation

IMPORTANT

Keysight recommends that a trained Keysight Application Engineer install and

setup the Double-Pulse Test Rack and Safety Enclosure. The instructions in this

guide are written for the trained Application Engineer.

End users should have the installation site prepared before beginning

installation. See “Customer Responsibilities” on page 16.

This System Installation Guide provides step-by-step instructions to assemble

and install the PD1500A Dynamic Power Device Analyzer/Double-Pulse Tester.

Note that the PD1500A is part of the overall PD1000A Power Device

Measurement System for Advanced Modeling.

In this chapter:

Customer Responsibilities page 16

Rack and Safety Enclosure Dimensions and Weight page

16

Tools Supplied for Installation and Instrument

Removal page 16

Electrical and Environmental Requirements page 18

Mains Disconnect page 19

Optional Safety Ground Connection page 19

Receiving The Rack and Safety Enclosure and Test

Instruments page 20

Moving the Rack and Safety Enclosure page 20

Inventory the Shipment page 21

Static-safe Handling Procedures page 23

Simplified System Diagrams page 25

16 Keysight Double-Pulse Test System Installation Guide

Site Preparation Customer Responsibilities

Customer Responsibilities

This System Installation Guide provides instructions for a Keysight-trained

Application Engineer to install the Keysight PD1500A DPT System Rack and

Safety Enclosure.

Rack and Safety Enclosure Dimensions and Weight

Tools Supplied for Installation and Instrument Removal

-T30 Torx screwdriver to remove/attach test rack rear panels

-3 mm L-shaped hex key wrench

-T25 L-shaped Torx key wrench

-T9 Torx screwdriver to attach Heater/Thermocouple assembly to DUT

-Large, 6 mm flat blade screwdriver to remove/attach test rack side panels

-Small flat blade screwdriver to attach N1294A GPIO-BNC adapter

-#2 PoziDrive screwdriver to install rack mounting kits

-Side cutters to remove cable ties

Receive the Double-Pulse Test System (multiple shipping containers). See page 20

Ensure the operating environment (space, noise, etc.) is suitable. See page 18.

Electrical and environmental requirements are met. See page 18

Provide a qualified electrician to do one of the following. See page 18

•permanently hard wire the free end to the AC power source

or

•attach an IEC 60309 AC power plug (L+N+P 6h is recommended) to the AC power cable

(a matching IEC 60309 AC Power receptacle must also be installed). IEC 60309

connectors are not included with the PD1500A system.

Host Computer requirements.

Additional supplies (host computer, LAN cable, etc.) are not included.

Weight Height Depth Width

Shipping Crate (with DPT Rack and

Safety Enclosure)

300 kg

(660 lbs)

167 cm

(65.75 in)

92 cm

(36.25 in)

120 cm

(47.25 in)

Rack and Safety Enclosure alone

(no test equipment installed)

150kg

(330.7lbs) 160 cm

(63 in.)

70 cm

(27.6 in.)

100 cm

(39.4 in.)

Rack and Safety Enclosure

(all test equipment and fixtures

installed)

162.5 kg

(358 lbs

for removing Work Surface. Your system

will have only one type of screw head.

}

Keysight Double-Pulse Test System Installation Guide 17

Double-Pulse Test Rack and Safety Enclosure Location Site Preparation

Double-Pulse Test Rack and Safety Enclosure Location

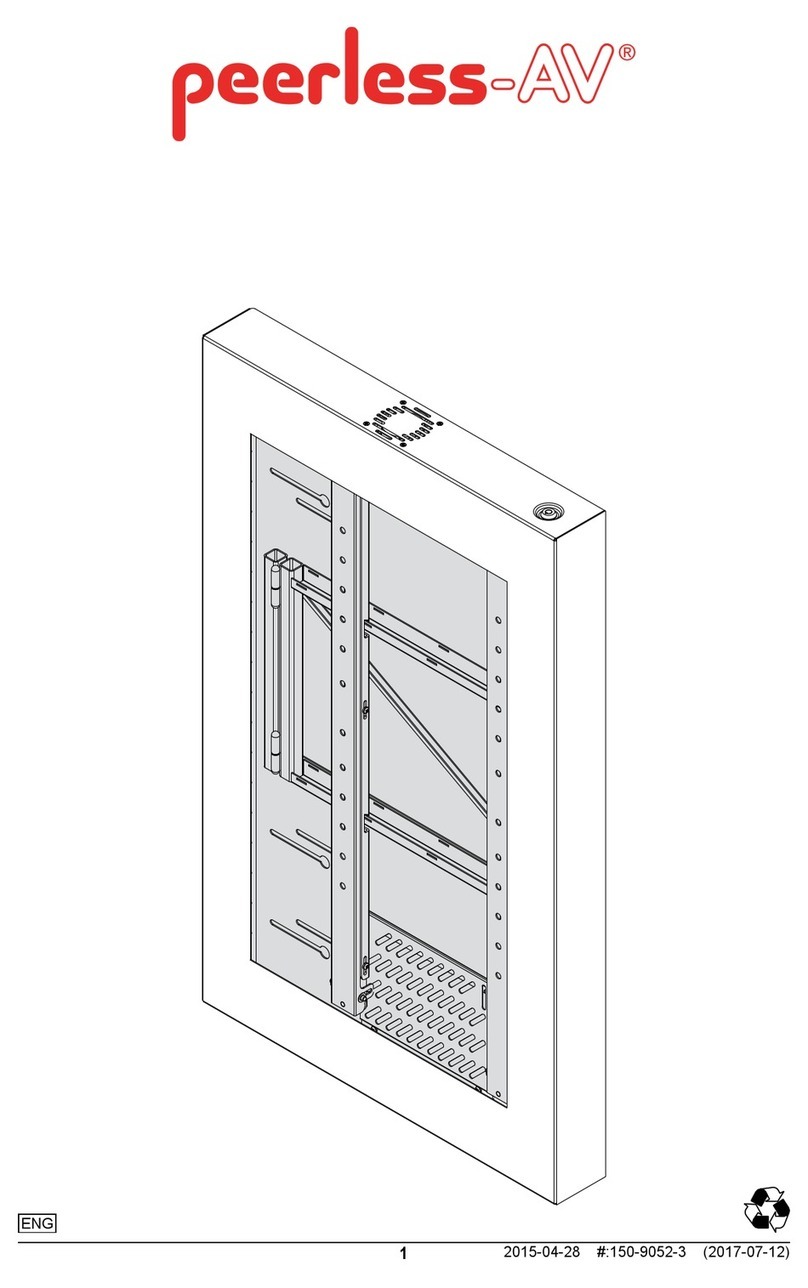

The DPT Rack and Safety Enclosure is a free-standing rack with test instruments

installed and a Safety Hood on top. It is the customer’s responsibility to consider

the anticipated location and requirements to ensure safety and optimize access

to test and control instrumentation.

The following figure shows a typical layout for the Rack and Safety Enclosure.

You should allow a minimum one meter of space in front of the rack for operator

access, one meter of space behind the system for service and 61 cm on either

side of the rack for sufficient air flow for cooling and ventilation.

Allow a minimum of one meter above the Rack and Safety Enclosure for opening

the Safety Enclosure hood.

Operator Area

(for example purposes only.

The operator does not have to

be in front of the test system.)

Instrument and

Service Access Area

(minimum required for

ventilation)

100 cm (39.4 in)

50 cm

(20 in)

50 cm

(20 in)

Rack Front

Keysight

Double Pulse Rack

and Safety Enclosure

(top view)

The Air Intake fans on the rack sides are temperature controlled.

They turn on only when the temperature in the lower portion of

the rack exceeds approximately 30 °C.

18 Keysight Double-Pulse Test System Installation Guide

Site Preparation Electrical and Environmental Requirements

Electrical and Environmental Requirements

Connect the DPT Rack and Safety Enclosure to AC Mains

AC Power Cord

A mains power cord, (8121-3445 for N. America and Japan, or 8121-3356 for all

other countries) 2.5 m long, Type A, IEC-60320 C19 to Type B Free End) is

supplied with the PD1500A. A qualified electrician must either:

–permanently hard wire the free end to the AC power source

or

–attach an IEC 60309 AC power plug (recommended) to the cable (a

matching IEC 60309 AC Power receptacle must also be installed). IEC

60309 connectors are not included with the PD1500A system.

Input Voltage Operating

Temperature

Operating Humidity Operating

Environment

200-240 VAC, 10 %,

Maximum Power rating 13A,

Typical 600 VA, 50/60 Hz

20 °C to +30 °C 50% to 80% RH,

Non-condensing

Indoor location only

The Double-Pulse Test Rack and Safety Enclosure is designed to

operate on 200 to 240 VAC single phase. Do not attempt to

operate the DPT Rack and Safety Enclosure on 120 VAC.

AC wiring and the Mains Disconnect are subject to local

and regional electrical codes. A licensed electrician must

determine and install the appropriate Mains Disconnect.

Copper wire must be used in the power drop. A licensed

electrician must determine the wire size for the power drop

according to local and regional electrical codes. The wires

must be sized to ensure that the voltage at the system does

not drop below 90% of the nominal voltage.

Keysight Double-Pulse Test System Installation Guide 19

Electrical and Environmental Requirements Site Preparation

Mains Disconnect

A mains disconnect - providing over-current and short circuit protection - must

be provided. It disconnects the mains circuits from the mains supply. It may be a

switch disconnect or a circuit breaker. The DPT Rack and Safety Enclosure front

panel switch is only a standby switch and is not a LINE switch (disconnecting

device). The disconnect must:

–Open all line conductors and neutral conductors where local code applies,

but do not open the protective earth conductor.

–Be marked “System Mains Disconnect” or the equivalent in your language.

–Be marked with a “|” for the “On” position or a “O” for “Off.”

–Be capable of being locked in the “Off” position but not in the “On”

position.

–Be installed within three meters of the DPT Rack, where it can be easily

reached by the system operator without requiring the system to be moved

to access the disconnect.

Convenience outlets should be installed near the system for external equipment

such as computers and monitors, etc. Locate the outlets within one meter (three

feet) of the rear of the system.

Optional Safety Ground Connection

This DPT Rack and Safety Enclosure must be grounded properly for proper

operation and safety. Because the rack is connected to the AC mains by a

plug/socket connection, Keysight recommends a redundant permanent earth

ground connection to reduce the risk of electric shock.

LEAKAGE CURRENT! Due to the types of instruments installed in

this cabinet, there is a risk of leakage current (> 3.5 mA). Reliable

ground circuit continuity is required for safe operation of this

product. To reduce the risk of electrical shock, an earth (ground)

connection is essential before connecting the AC power mains.

Never operate the system with the ground connector

disconnected. Use a permanent safety ground connection

(recommended) or a plug meeting the IEC 60309 (CEE plug)

requirements.

A Safety Ground wire is not supplied with the DPT Rack and Safety

Enclosure and must be installed by a qualified electrician familiar

with local electrical codes.

20 Keysight Double-Pulse Test System Installation Guide

Site Preparation Receiving The Rack and Safety Enclosure and Test Instruments

Receiving The Rack and Safety Enclosure and Test Instruments

Your DPT Rack and Safety Enclosure shipment arrives in multiple shipping

containers. Before uncrating the Rack and Safety Enclosure or unpacking any

test instrument, carefully inspect the shipping containers for any damage that

may have occurred during shipment such as:

–dents

–scratches

–cuts

–water damage

Report any damage to the shipping agent immediately, as such damage is not

covered by the Keysight warranty.

Make sure that all doors, elevators, and passageways in route to the site are

large enough to accommodate the rack and are capable of carrying the weight.

The packaged physical specifications for the racks are listed in the “Rack and

Safety Enclosure Dimensions and Weight” on page 16. Floor elevators and lifting

equipment must be of sufficient capacity. If the rack or other instrument shipping

crate is damaged upon receipt, request that the carrier's agent be present when

the protective covering is removed. Inspect the rack and instruments for damage

(scratches, dents, bent pieces, etc.). If the rack or any instrument is damaged,

notify the carrier and the nearest Keysight Technologies Sales and Service office

immediately.

Moving the Rack and Safety Enclosure

On initial receipt, the Rack and Safety Enclosure exceeds 150 kg (330 lbs). This

does not include the weight and size of the shipping crate.Use a mechanical lift

to lift the shipping crate. The rack has casters for moving it around on a level

floor.

When transporting the Rack and Safety Enclosure for long distances or outside

of a building always make sure that the environmental conditions like humidity,

temperature and air pollution never exceed the related instrument specification.

The temperature should not exceed -20 °C to +60 °C.

Keysight Double-Pulse Test System Installation Guide 21

Receiving The Rack and Safety Enclosure and Test Instruments Site Preparation

Inventory the Shipment

–The DPT Rack and Safety Enclosure comes in multiple shipping containers.

Use the packing list that comes with your system to ensure you received all

pieces of the system. DPT Rack and Safety Enclosure (includes 2.5 m C19

power cord, unlocking tool, etc). The rack has the following instruments

preinstalled:

-- Keysight 33512B Waveform Generator with ARB (installed in the back

of the rack)

-- Keysight B2902B Precision Source/Measurement Unit

-- Heinzinger EVO High Voltage Power Supply

–The following items are shipped separately:

-- Depending on availability, either the:

Keysight DSOS104 4-Channel Oscilloscope with PD1500A orders

prior to February 2022

or

Keysight MXR108 8-Channel Oscilloscope with PD1500A orders

after February 2022. This oscilloscope can be used when upgrading

the PD1500A.

-- PD1000-68701 DPT Test Fixture

-- Oscilloscope Probes

--N2873A 10:1 Oscilloscope Probe (qty. 4 supplied with oscilloscope)

--10076C 100:1 High Voltage Oscilloscope Probe (10076-60003)

--N2819A Differential Oscilloscope Probe, 10:1, 800 MHz

--PD1000-60002 Oscilloscope Protection Probe (uses 8121-2816 BNC

to SMA cable to go from Probe to Coaxial Shunt)

-- 8121-2816 BNC to SMA Cable 1 M (quantity 1) (to go from Oscilloscope

Protection Probe to Coaxial Shunt)

-- 1855-2942 SCT2080 N-Channel, SiC Power MOSFETs. For performing

sample DPT tests (quantity 2)

-- 8710-1582, 0.56 N-m (5 lb-in) 5/16 in Break-over torque wrench for

SMA connections

-- PD1000-00004 Set of hand tools

-- One roll Polyimide (Kapton) tape. 0.75” wide, 33 M Long, 2.7 MIL thick

22 Keysight Double-Pulse Test System Installation Guide

Site Preparation Receiving The Rack and Safety Enclosure and Test Instruments

The following cables and adapters are used only for the AutoCal procedure:

-- 1251-2277 Banana to BNC Adapter, quantity 1

-- 8121-2816 BNC to SMA Cable, 1 m, 50 , quantity 1

-- U1168B Standard Probe Kit, quantity 2

-- 1258-0225, 2.54 mm jumpers, quantity 10

Optional Si/SiC Device Test Modules (at least one set is required1):

-- PD1000-60901 DUT module (Power Loop) for TO-247, 3-pin devices

-- PD1000-60902 DUT module (Power Loop) for TO-247, 4-pin devices

-- PD1000-62401 DUT module (Power Loop) for D2PAK7 device package

-- PD1000-61901 Characterized 10 m

-- PD1000-61902 Characterized 100 m Coaxial Shunt

-- Gate Drive Modules for Si/SiC devices

-- PD1000-66505 PCA Clamp Circuit module

-- PD1000-62001 Device Heater kit with integrated Type K Thermocouple

1 Note: a minimum of one DUT module, one Gate Drive pair, and one Coaxial Current Shunt are required for the

PD1500A. The Clamp Circuit module and the Device Heater Kit are not required.

Low-Side Gate Drive Modules

PD1000-66540 No installed Gate Resistor

PD1000-66542 0 (2x 0 Gate Resistor

PD1000-66544 10 (2x 4.99 Gate Resistor

PD1000-66546 100 (2x 50 Gate Resistor

PD1000-66848 ±28 V, No Gate Resistor installed

PD1000-66850 ±28 V, 0 Gate Resistor installed

PD1000-66852 ±28 V, 4.4 Gate Resistor installed

PD1000-66854 ±28 V, 9.4 Gate Resistor installed

PD1000-66856 ±28 V, 20 Gate Resistor installed

PD1000-66858 ±28 V, 44 Gate Resistor installed

PD1000-66860 ±28 V, 200 Gate Resistor installed

Using these optional

±28 V gate drive

modules requires

PD1000A control

software version

2022.321 or later

High-Side Gate Drive Modules

PD1000-66541 No installed Gate Resistor

PD1000-66543 0 (2x 0 Gate Resistor

PD1000-66545 10 (2x 4.99 Gate Resistor

PD1000-66547 100 (2x 50 Gate Resistor

PD1000-66849 ±28 V, No Gate Resistor installed

PD1000-66851 ±28 V, 0 Gate Resistor installed

PD1000-66853 ±28 V, 4.4 Gate Resistor installed

PD1000-66855 ±28 V, 9.4 Gate Resistor installed

PD1000-66857 ±28 V, 20 Gate Resistor installed

PD1000-66859 ±28 V, 44 Gate Resistor installed

PD1000-66861 ±28 V, 200 Gate Resistor installed

Using these optional

±28 V gate drive

modules requires

PD1000A control

software version

2022.321 or later

Other manuals for PD1500A

2

Table of contents