2007 > 2.7L V6 GASOLINE >

TROUBLESHOOTING

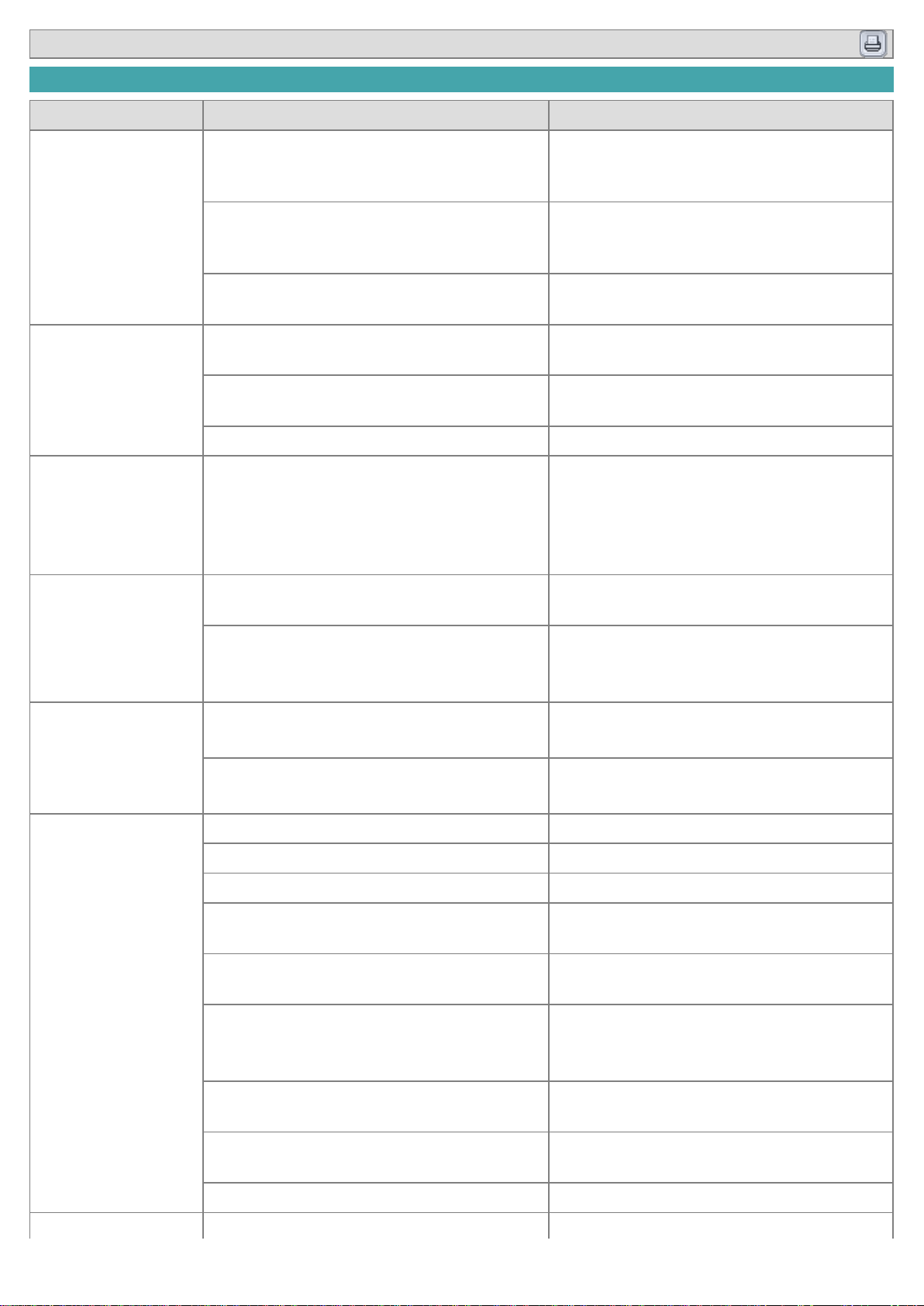

Symptom Suspect area Remedy

Engine misfire with

abnormal internal

lower engine noises.

Worn crankshaft bearings.

Loose or impropes engine drive plate. Replace the crankshaft and bearings as

required.

Repair or replace the drive plate as required.

Worn piston rings.

(Oil consumption may or may not cause the

engine to misfire.)

Inspect the cylinder for a loss of compression.

Repair or replace as required.

Worn crankshaft thrust bearings Replace the crankshaft and bearings as

required.

Engine misfire with

abnormal valve train

noise.

Stuck valves.

(Carbon buildup on the valve stem) Repair or replace as required.

Excessive worn or mis-aligned timing chain. Replace the timing chain and sprocket as

required.

Worn camshaft lobes. Replace the camshaft and valve lifters.

Engine misfire with

coolant consumption. a. Faulty cylinder head gasket and/or

cranking or other damage to the cylinder

head and engine block cooling system.

b. Coolant consumption may or may not

cause the engine to overheat.

a. Inspect the cylinder head and engine

block for damage to the coolant passages

and/or a faulty head gasket.

b. Repair or replace as required.

Engine misfire with

excessive oil

consumption.

Worn valves, guides and/or valve stem oil

seals. Repair or replace as required.

Worn piston rings.

(Oil consumption may or may not cause the

engine to misfire)

a. Inspect the cylinder for a loss of

compression.

b. Repair or replace as required.

Engine noise on start-

up, but only lasting a

few seconds.

Incorrect oil viscosity. a. Drain the oil.

b. Install the correct viscosity oil.

Worn crankshaft thrust bearing. a. Inspect the thrust bearing and crankshaft.

b. Repair or replace as required.

Upper engine

noise,regardless of

engine speed.

Low oil pressure. Repair or replace as required.

Broken valve spring. Replace the valve spring.

Worn or dirty valve lifters. Replace the valve lifters.

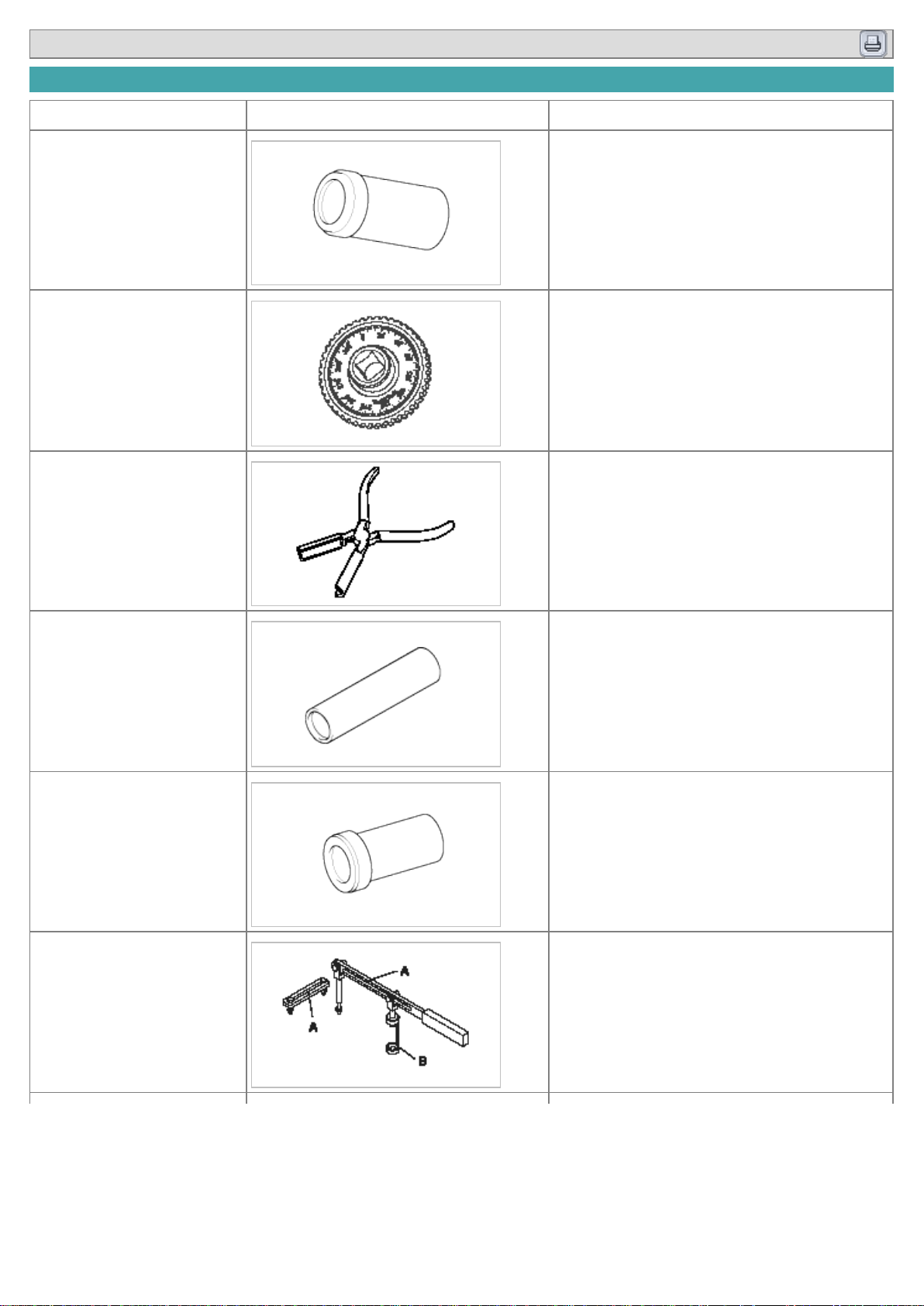

Stretched or broken timing chain and/or

damaged sprocket teeth. Replace the timing chain and sprockets.

Worn timing chain tensioner, if applicable. Replace the timing chain tensioner as

required.

Worn camshaft lobes. a. Inspect the camshaft lobes.

b. Replace the timing camshaft and valve

lifters as required.

Worn valve guides or valve stems. Inspect the valves and valve guides,then

repair as required.

Stuck valves. Carbon on the valve stem or

valve seat may cause the valve to stay open. Inspect the valves and valve guides, then

repair as required.

Worn drive belt, idler, tensioner and bearing. Replace as required.

Lower engine

noise,regardless of Low oil pressure. Repair as required.