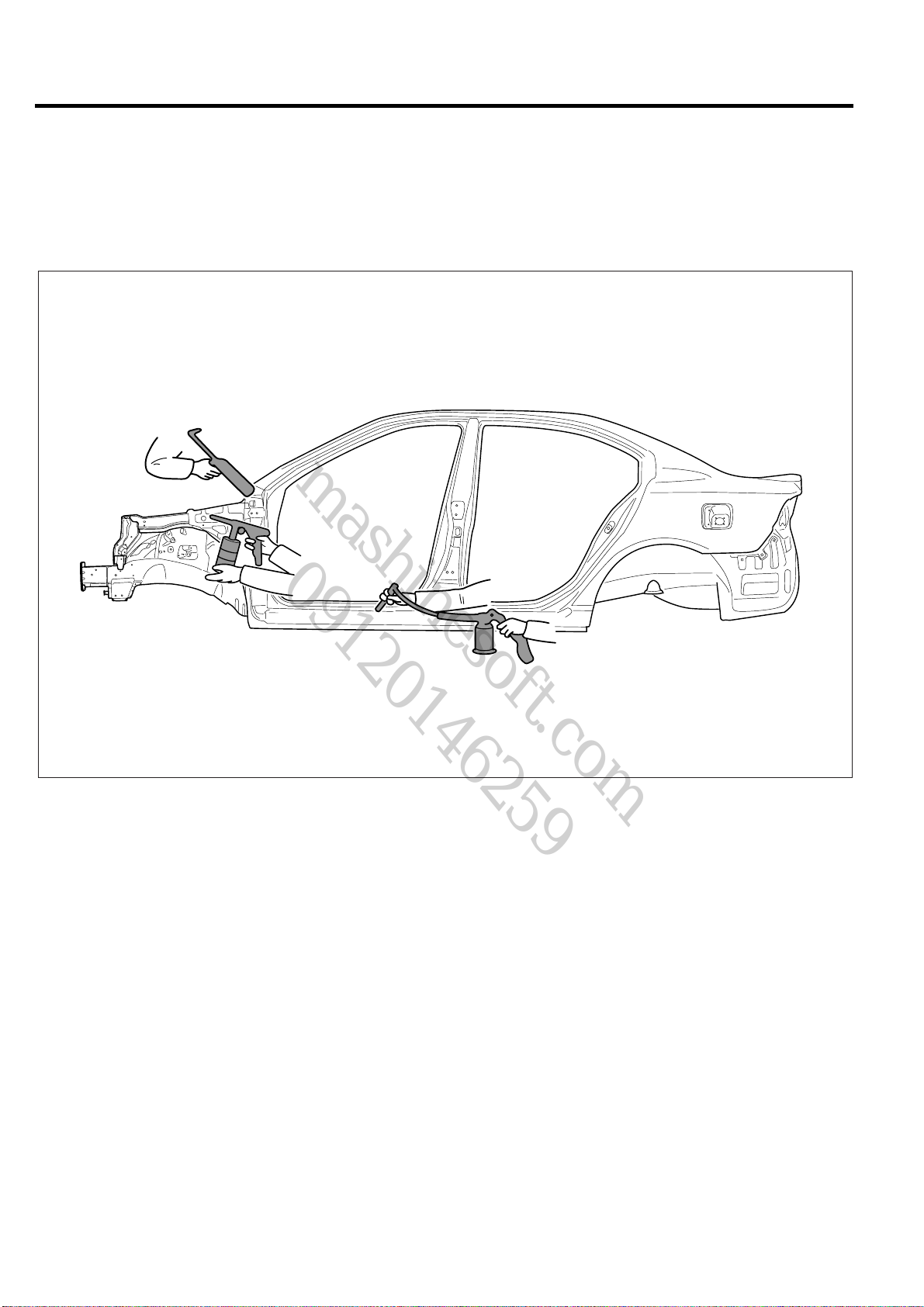

IN THIS MANUAL

Proper service methods and repair procedures are essential for safe, reliable operation of all

motor vehicles as well as personal safety of the operator. The service procedures and

descriptions in this shop manual provide general directions for a service and repair.

Procedure, techniques, tools, and parts for service including the skill of the technician vary.

It is impossible to provide advice or caution as to each case in this manual.

Accordingly, anyone who intends to use a replacement part, service procedure, or tool, which is

not recommended by the vehicle manufacturer, must first assure thoroughly that neither their

personal safety nor the safe operation of the vehicle will be first jeopardized by the replacement

part, service procedure, or tool they select.

The following list contains some general WARNINGS that you should follow while working on a

vehicle.

Always wear safety glasses for eye protection.

Use safety stands whenever a procedure requires you to be under the vehicle.

Make sure that the ignition switch is always in the OFF position, unless otherwise required by

the procedure.

Set the parking brake when working on the vehicle. If you have an automatic transaxle, set in

park unless instructed otherwise for a specific operation

Place supporters against the front and rear surfaces of the tires to help prevent the vehicle

from moving

Operate the engine only in a well-ventilated area to avoid the danger of carbon monoxide

poisoning.

Keep yourself and your clothing away from moving parts when the engine is running,

especially the drive belts.

To prevent serious burns, avoid contact with hot metal parts such as the radiator, exhaust

manifold, tail pipe, catalytic converter and muffler.

Do not smoke while working on a vehicle.

To avoid injury, always remove rings, watches, loose hanging jewelry, and loose clothing

before beginning to work on a vehicle.

When it is necessary to work under the hood, keep hands and other objects clear of the

radiator fan blades! Your vehicle may be equipped with a cooling fan that may turn on, even

though the ignition switch is in the OFF position. For this reason care should be taken to

ensure that the radiator fan electric motor is completely disconnected when working under the

hood and the engine is not running.

Remind you to be especially careful in those areas where carelessness can

cause personal injury.

To prevent you from making errors that could damage the vehicle as well as

personal injury.

Gives you added information that will help you complete a particular procedure.

WARNING :

CAUTION :

NOTE :

IMPORTANT SAFETY NOTICE

mashinesoft.com

09120146259