11

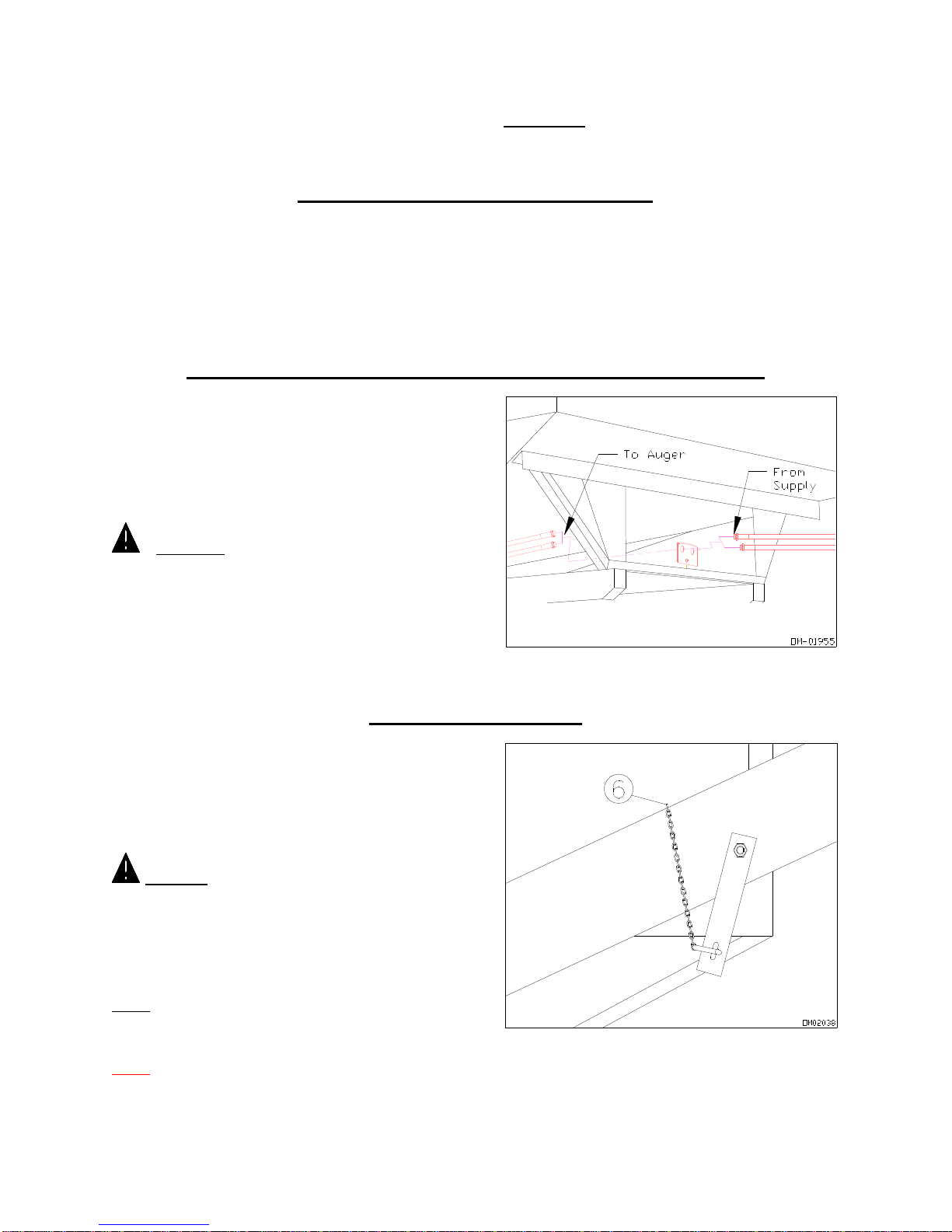

auger is not, switch incoming hydraulic lines or

refer to assembly instructions.

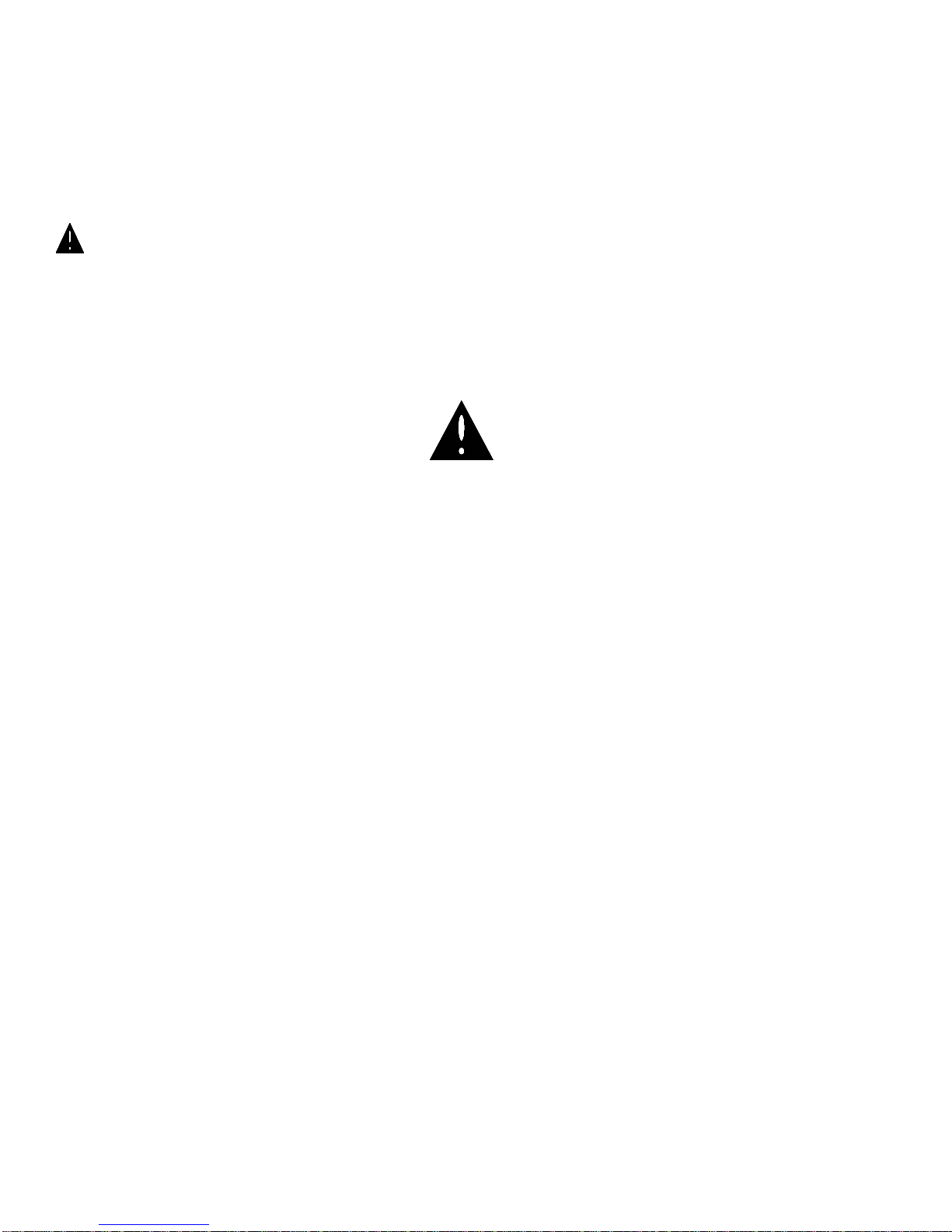

WARNING! BE SURE THAT ALL CLEAN-OUT

DOORS ARE CLOSED WHEN OPERATING. KEEP

HANDS, LOOSE CLOTHING, ETC. FROM MOVING

PARTS; FAILURE TO DO SO COULD RESULT IN

SERIOUS BODILY HARM.

8. Once the auger has begun to rotate, open

hopper door. Be sure to regulate flow from

gravity box into the hopper for optimum

performance.

NOTE: To achieve optimum performance, test by

placing auger at different angles. The position of the

auger depends on the type of material being handled.

NOTE: Use pressurized water to washout auger and

hopper after using fertilizer. See SERVICE section.

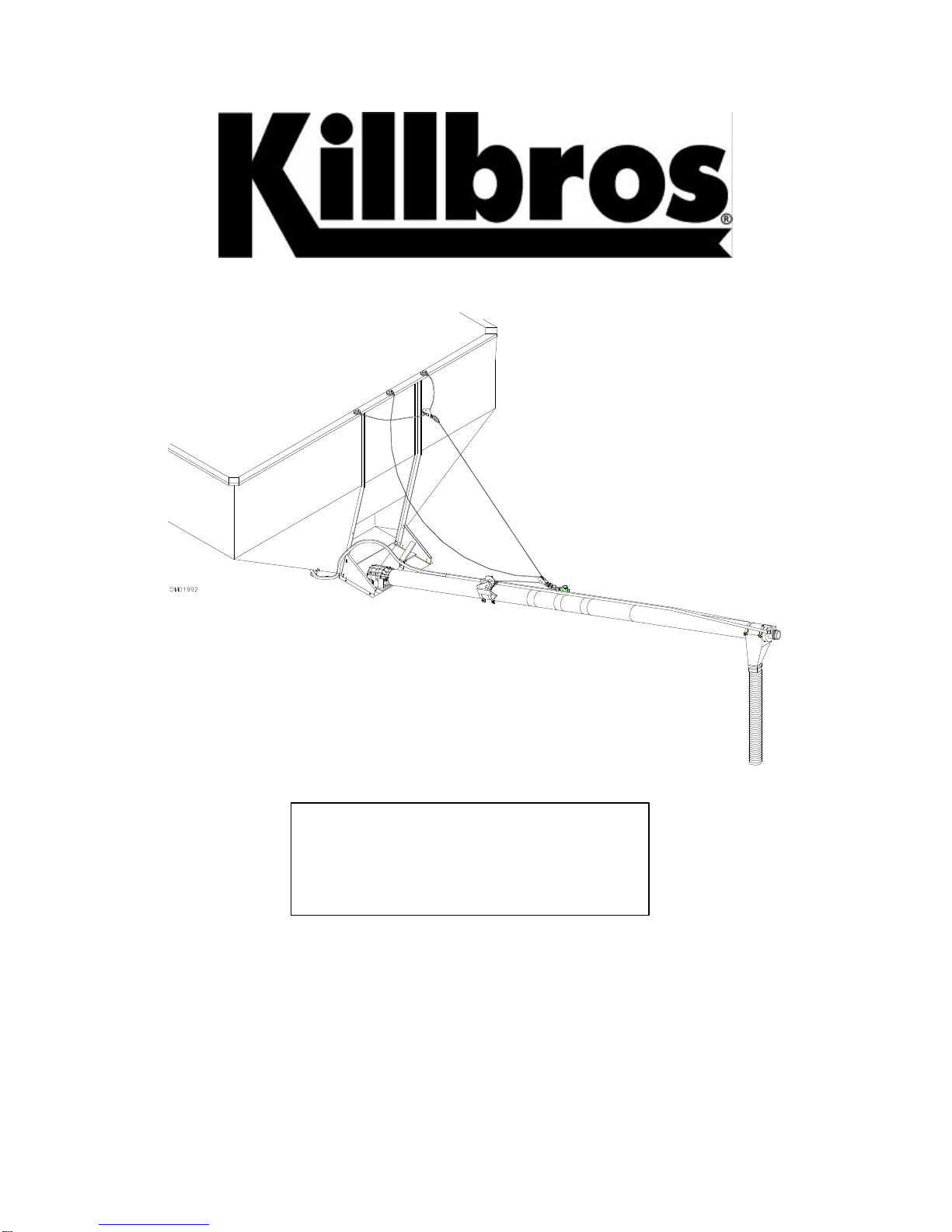

TRANSPORTING

BEFORE TRANSPORTING

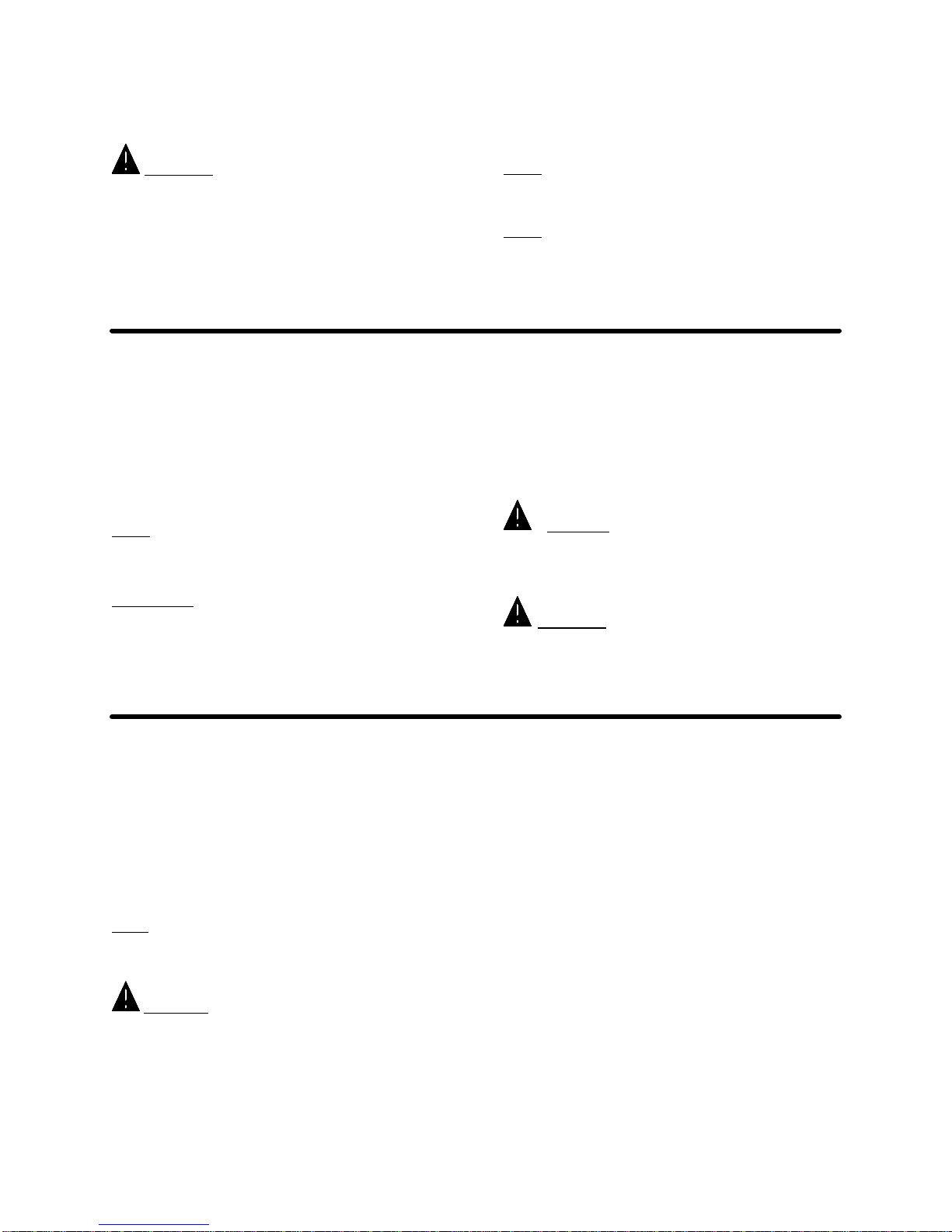

Be sure to completely empty auger by closing gravity

box door and allowing auger to run. Turn the auger

off and raise into position over transport bracket and

lower into position, while securely holding the winch

handle. Once in place, lock the winch and tighten

cable so that it is taut. Finally, reposition safety chain

around auger and secure.

NOTE: Auger must be empty before transporting,

failure to do so voids warranty.

DURING TRANSPORTING

IMPORTANT: Before transporting, be sure that auger

is securely mounted in transport bracket.

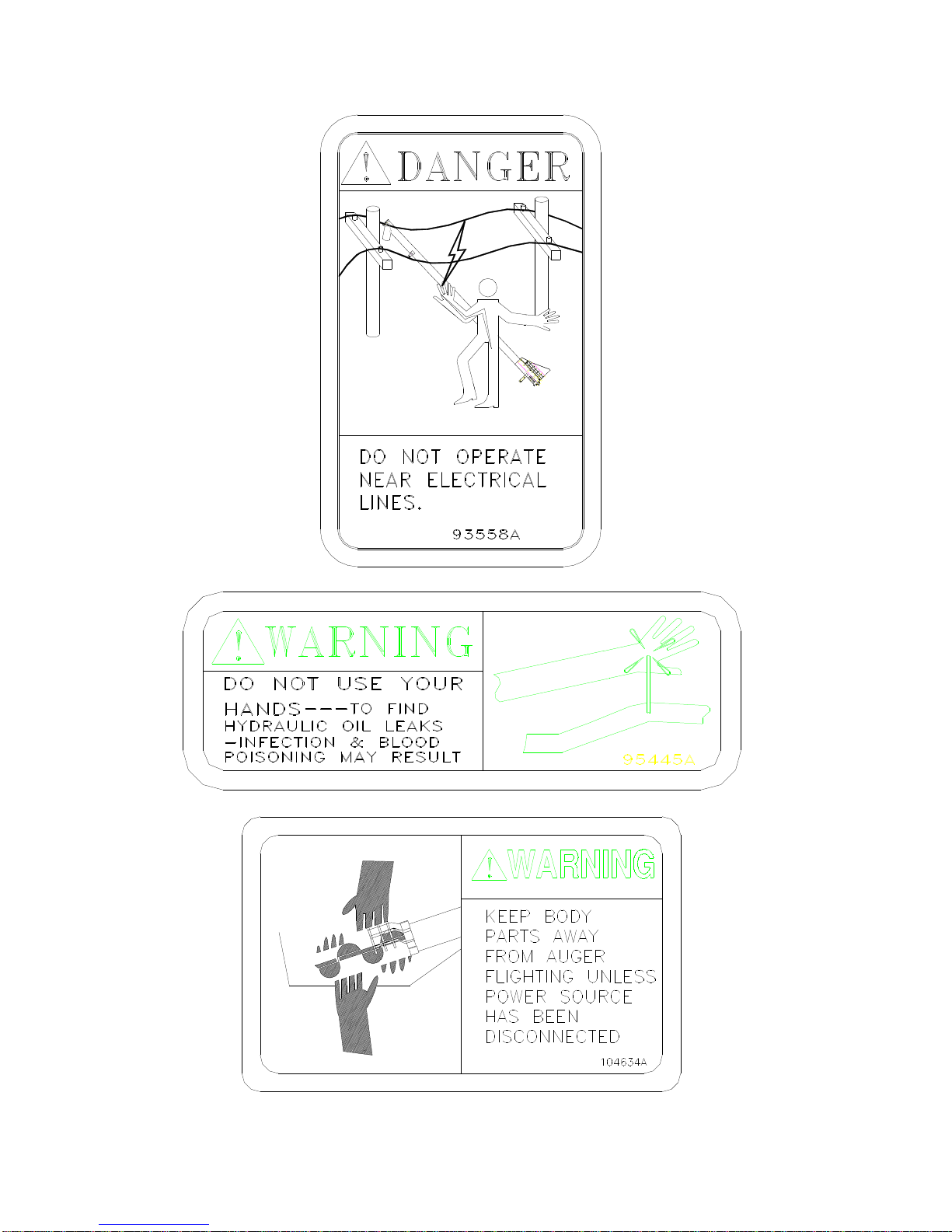

Use caution when traveling, do not attempt to

transport unit under low hanging tree branches

overhead telephone wires or electrical wires. Be

aware of transport height of unit or damage could

occur.

Comply with all state and local laws governing

highway safety and regulations when moving

equipment on public roads.

CAUTION! USE APPROVED LIGHTS,

REFLECTORS, AND DEVICES WHEN

TRANSPORTING AT NIGHT AND DURING

PERIODS OF POOR VISIBILITY.

WARNING! ALWAYS TRAVEL AT A SPEED

WHICH PERMITS COMPLETE CONTROL OF

EQUIPMENT.

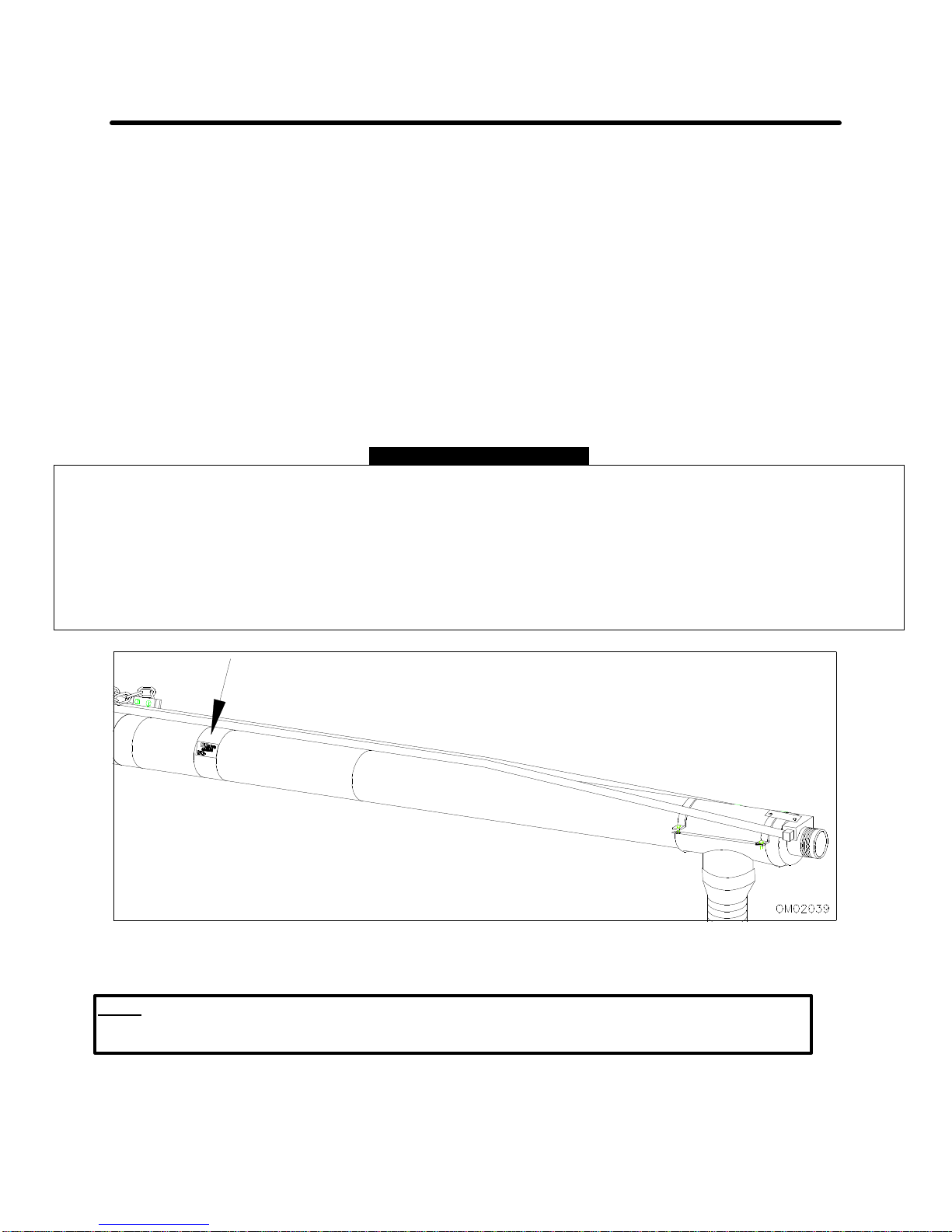

PERFORMANCE

MAXIMUM OPERATING PRESSURES:

•Continuous 1500 psi (min. 1000 psi).

•Peak (10% of Duty Cycle) 2250 psi.

•Back Pressure 1000 psi.

•Maximum Oil Flow 12 GPM (min. 10 GPM).

•Recommended Oil Viscosity Range 100-200 S.S.U.

•Maximum Operating Temperature 180 degrees.

•Recommended Filtration 10 micron or finer.

NOTE: For hydraulic systems that exceed the recommended peak pressure or have greater than 12 GPM oil flow, a flow

control valve is recommended to bring the system down to the peak performance of the auger. The control valve will extend the

otherwise short life of the seals and motor of the auger. Contact your Killbros dealer for more information.

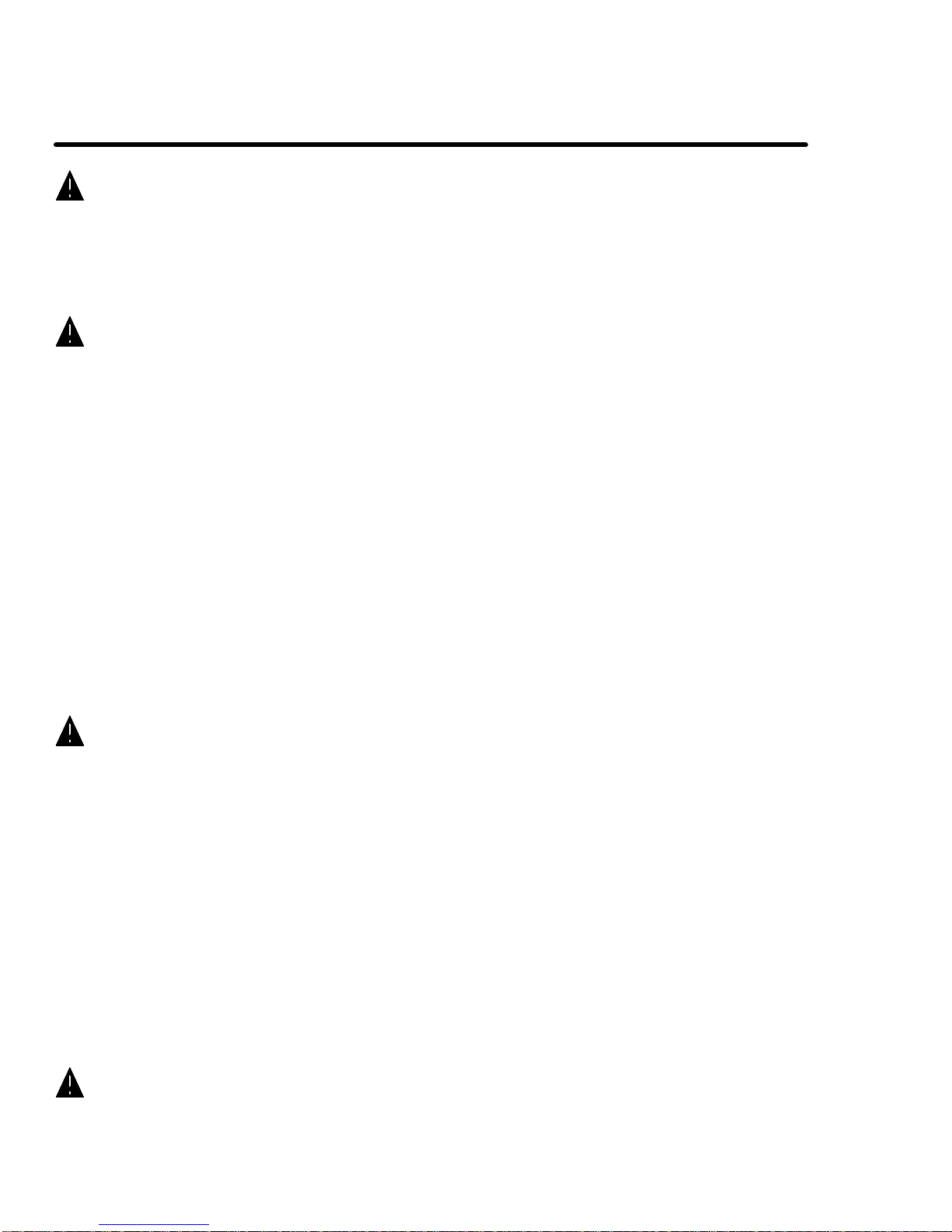

WARNING! BE SURE THAT THE OIL RESERVOIR OF THE HYDRAULIC SYSTEM IS REFILLED TO ITS PROPER

LEVEL AFTER AUGER IS PUT IN OPERATION.

AVOID:

•Large contamination particles in fluid such as machining chips or sand.

•Extreme high fluid temperatures that cause the motor to operate slowly and reduce the motor’s capability to lubricate

properly.