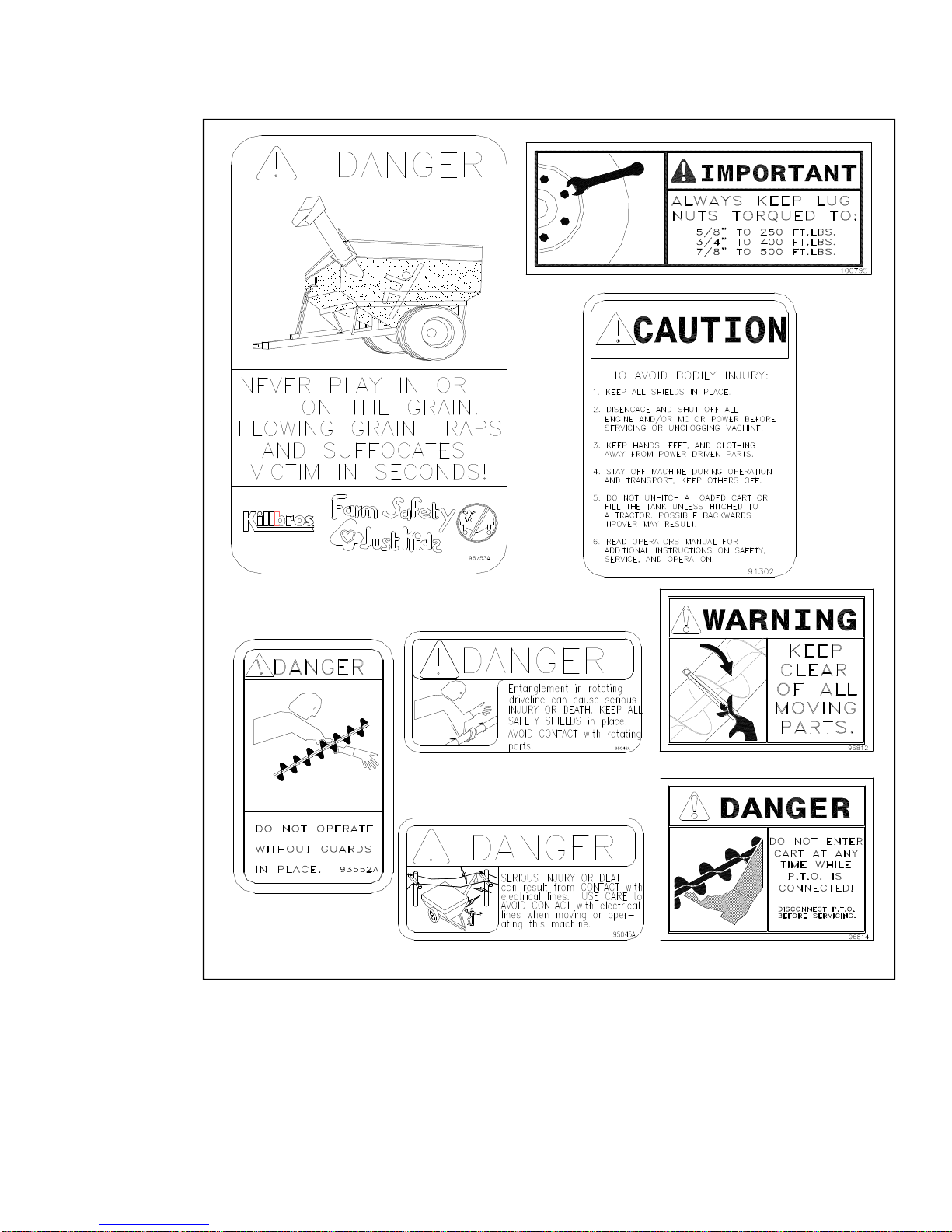

SAFETY

AVOID POSSIBLE INJURY

Always use safety precautions. Most acci-

dents are a result of failure to practice safety.

Accidents cause lost time and suffering. Do

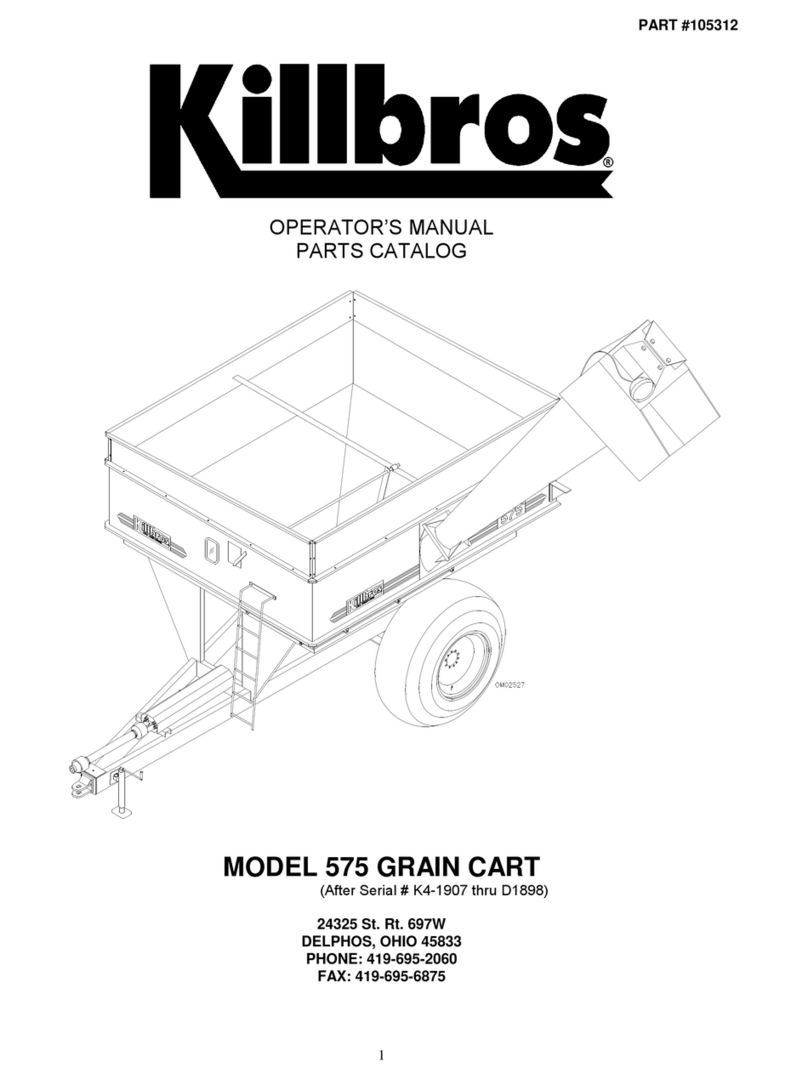

not operate the Grain Cart without reading

this manual thoroughly.

Follow all safety precautions as outlined in

this manual.

All machinery should be operated only by

those who are experienced and responsible

and have been delegated to do so.

BEFORE OPERATING

Be sure that all hardware is in place and

properly secured.

Keep safety signs clean and legible at all

times.

Check tire pressure so that it is at the rec-

ommended rating during operation.

Check box for any debris or excess grain

before each use.

Keep children and all unauthorized personnel

clear of work area.

Do not allow anyone to ride on the equip-

ment. Make sure everyone is clear before

operating the machine or tractor.

Always shut tractor engine off when working

on the unit.

Be sure that the clean-out doors are closed

and securely latched.

Keep body, hair, and clothing away from

moving parts.

DURING OPERATION

Keep children and all unauthorized personnel

clear of work area.

Never enter or climb on Grain Cart while the

auger is running.

Do not operate with safety shields removed or

clean-out door open.

Ensure that all personnel are clear before

moving the Cart.

Do not attempt to move any objects away

from moving parts.

Keep hands, feet, clothing, and objects away

from moving parts.

Do not grease equipment when in operation.

DO NOT allow ANYONE to enter the box at

any time, if entry is necessary, be sure chute

door is closed, P.T.O. is disengaged, and

tractor brakes are locked before entry.

BEFORE TRANSPORT

Make sure that all safety decals and reflec-

tors are clean and in place on the machine.

While attaching cart to tractor be sure you

can see the driver and the driver can see you

at all times to avoid being struck by the

tractor.

Comply with all state and local laws governing

highway safety when moving machinery.

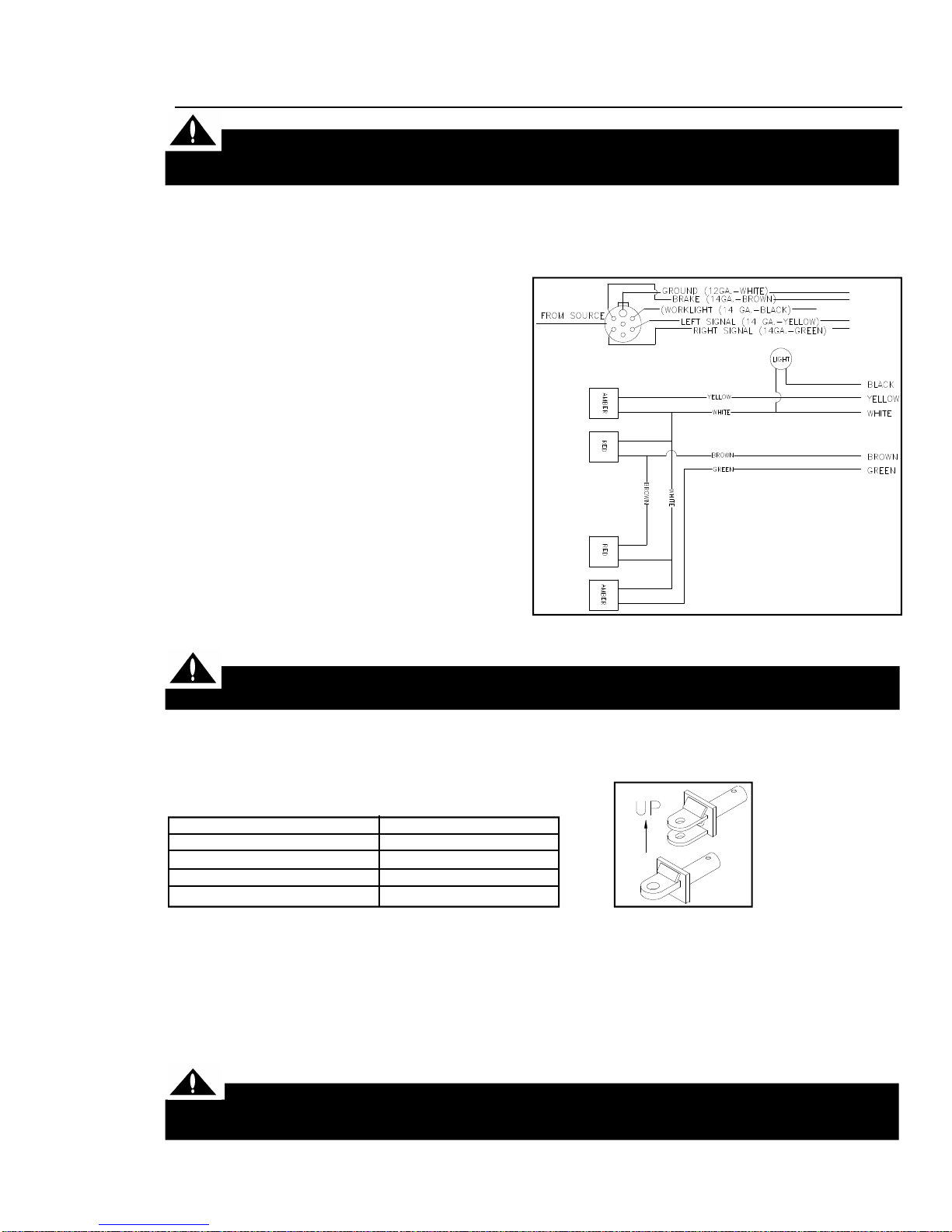

Use accessory lighting and warning lights when

transporting at night to adequately warn op-

erators of other vehicles.

When auger is not in use, be sure to fold to

rest position.

DURING TRANSPORT

Use good judgment when transporting imple-

ments on highways. Maintain complete control

at all times. Regulate speed to road condi-

tions.

Be careful when moving unit near electrical

lines with discharge auger up.

Drive at speeds slow enough to insure your

safety as well as others.

Regulate speed during off-road travel. Do not

travel faster than 8 M.P.H. loaded.

Due to the height and width of the implement,

use extra caution on highways, farm lanes,

and when approaching low and narrow clear-

ances.

Follow all regulations concerning weight limita-

tions on roadways, bridges, and overpasses.

Unit is to be towed at tractor speeds only. 20

M.P.H. maximum.

COMPLY WITH ALL SAFETY WARNINGS

AND CAUTIONS IN THIS MANUAL!