6TARGET ECO I FEEDING, rev.09

TARGET ECO I FEEDING

2SYSTEM’S OVERVIEW

2.1 Description of the controller

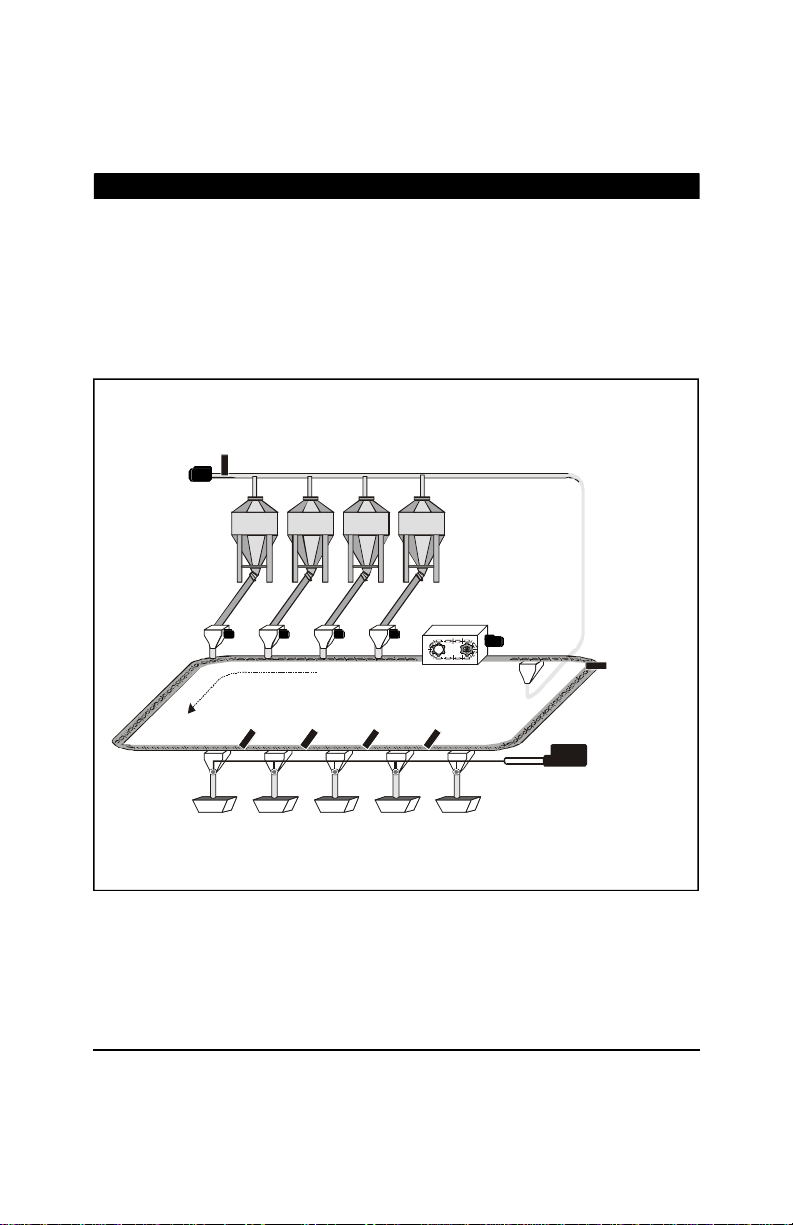

The ECOIFEEDING is an electronic device used to

distribute feed in hog barns. It is specially intended

for barns that are using a closed loop feeding system.

In all, the controller can distribute up to 8 different

types of rations. It can also adjust the composition

and the size of feed rations over time to suit the

animal’s needs.

The controller uses an external module called CDM-

1 to control the feeder motor and an external relay

panel to control the following outputs:

8ration augers;

96 drops;

1air compressor;

1actuator;

1cleanout auger;

9cleanout valves (1 master valve &

8 ration valves);

8timeclock outputs.

!

Refertothewiringdiagramenclosedat

the end of this manualtoconnectthe

variousdevices.

2.2 Main Features

Large LCD display

A large LCD screen offers an efficient interface for

displaying, monitoring and adjusting the parameters.

Individual control of 96 drops

Thecontroller can controlup to 96 independent feed

drops.

Actuator control for drops

The user can assign an actuator position to each

ration. This way, when a ration is delivered, the ac-

tuator open to the ration’s respective position, caus-

ing the opening of certain drops.

Ration curve

Ration curves provide an automatic adjustment of

the feeding periods and of the type of ration that is

distributed to the animals over time. It is thus pos-

sible to increase the number of feed cycles or to

switch rations as the animals grow up.

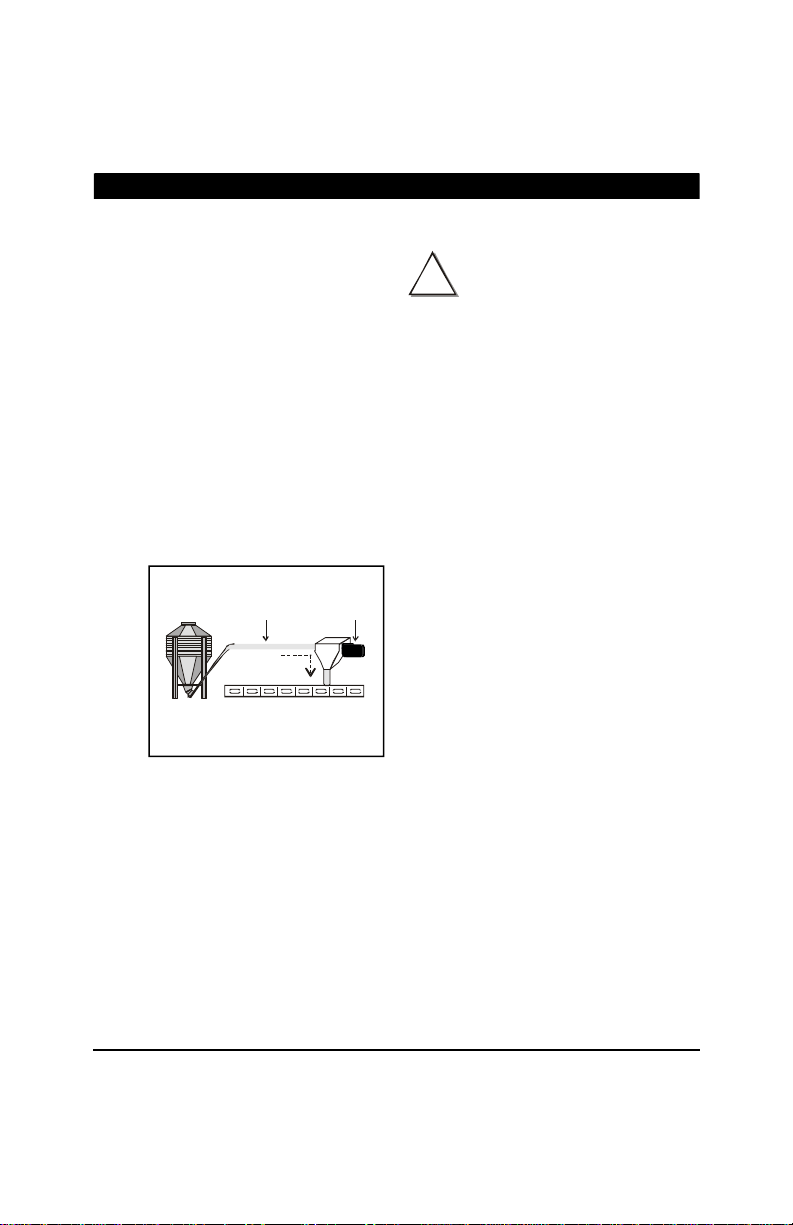

Cleanout

Cleanout periods allow evacuating feed leftovers

from the feed line. To evacuate the feed, the con-

troller restarts the feeder while the drops remain

opened. An optional cleanout auger can also be used

to send feed leftovers back to their original bin.

Animal inventory

The animal inventory function allows keeping track

of the number of animals in the barn. If drops are

controlled individually, the animal inventory is dis-

played separately for each one of them.

Fill auger run time

The controller has an history in which the run time

of each fill auger is recorded for the past 75 days.

8 clock outputs

The controller has 8 timers to control various de-

vices using the real-time clock.

Memory card

A memory card allows making a backup of the whole

controller configuration.

Alarm management

Weighing alarms are set off if a bin is empty and if any

kind of problem occurs on the distribution system.

Computer control

The controller can be connected to a computer, thus

making it possible to centralize the management of

information and diversify control strategies.