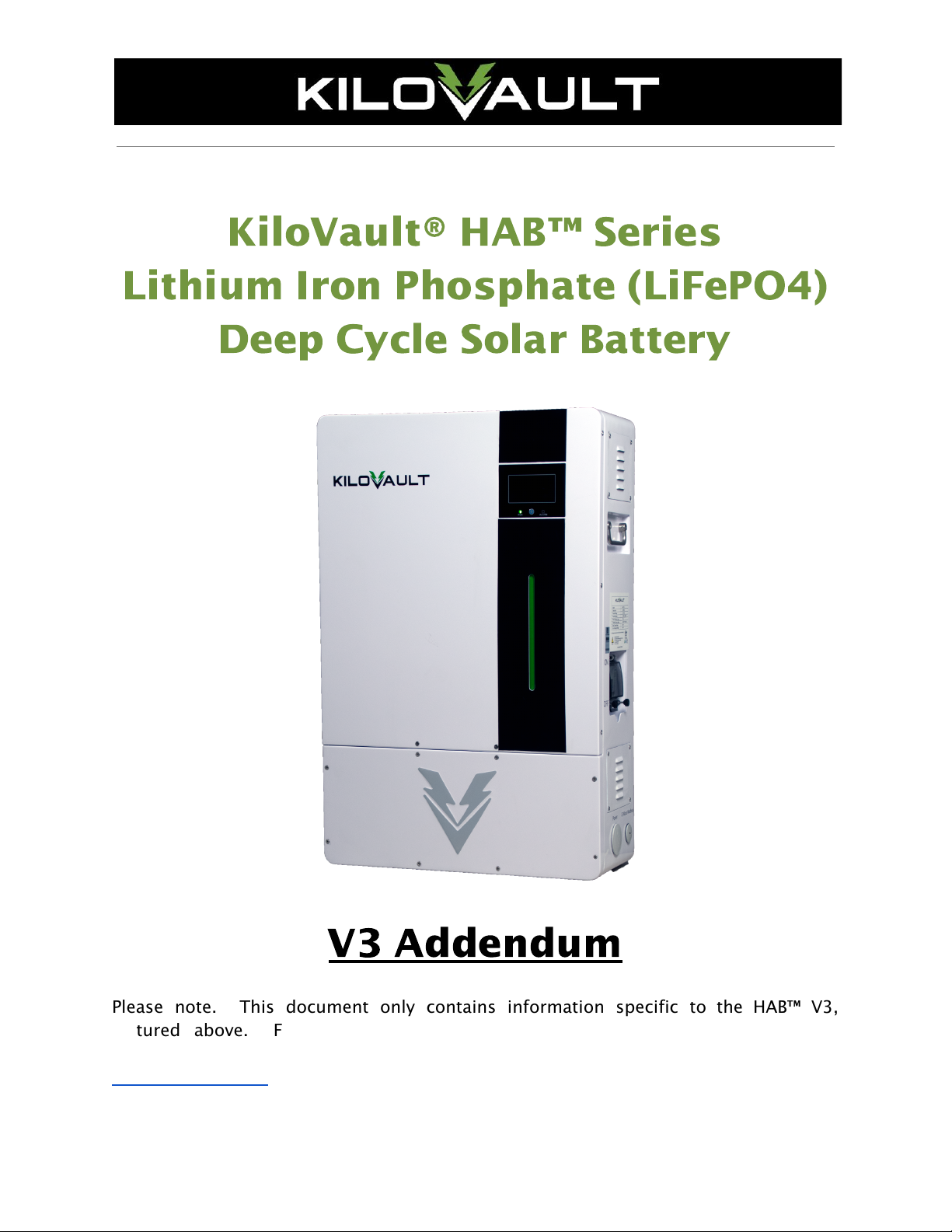

KiloVault HAB V3 Addendum User manual

Other KiloVault Camera Accessories manuals

KiloVault

KiloVault HAB 7.5 V4 Instruction Manual

KiloVault

KiloVault HAB Series User manual

KiloVault

KiloVault HLX Series User manual

KiloVault

KiloVault HLX+ User manual

KiloVault

KiloVault HAB Series User manual

KiloVault

KiloVault 2100 PLC User manual

KiloVault

KiloVault HLX Series User manual

KiloVault

KiloVault HAB Series User manual

Popular Camera Accessories manuals by other brands

Trojan

Trojan GC2 48V quick start guide

Calumet

Calumet 7100 Series CK7114 operating instructions

Ropox

Ropox 4Single Series User manual and installation instructions

Cambo

Cambo Wide DS Digital Series Main operating instructions

Samsung

Samsung SHG-120 Specification sheet

Ryobi

Ryobi BPL-1820 Owner's operating manual