2 of 28

Contents

1. Safety Information ............................................................................................................................. 5

1.1. Definitions .................................................................................................................................. 5

1.2. Important Safety Information .................................................................................................... 5

2. Overview............................................................................................................................................ 7

2.1. Product Technology .................................................................................................................... 7

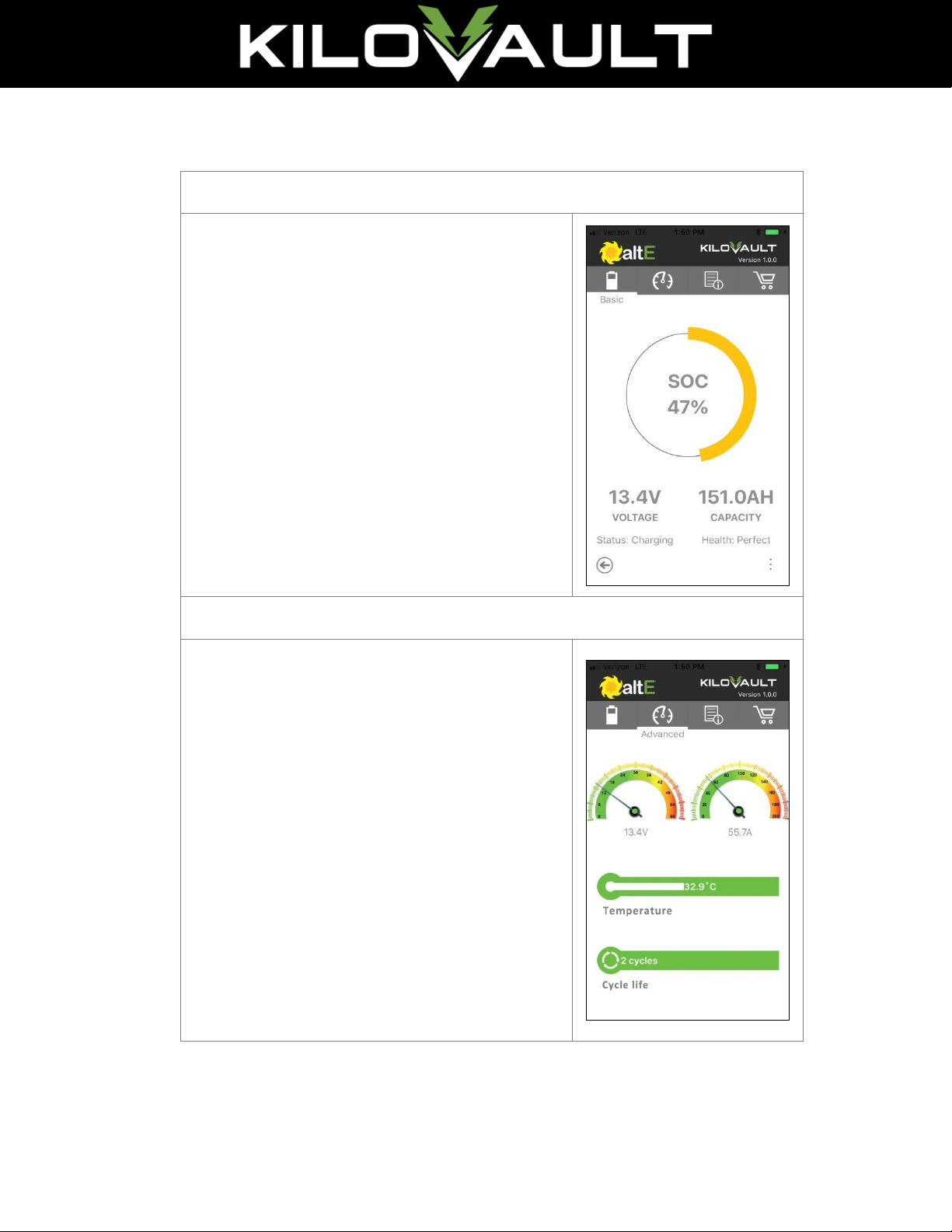

2.2. Bluetooth Monitoring Application ............................................................................................. 7

3. Installation Requirements ................................................................................................................. 9

3.1. Pre-Installation ........................................................................................................................... 9

3.1.1. All Batteries Must Be Fully Charged to the Same Voltage Prior to Use .............................. 9

3.1.2. Do Not Use DC Chargers Exceeding 150 Amps ................................................................. 10

3.1.3. Add Batteries of Exact Same Model Together .................................................................. 11

3.1.4. Disable Your Chargers Equalizing Cycle............................................................................. 11

3.1.5. Do Not Use a Battery Temperature Sensor (BTS).............................................................. 11

3.1.6. Temperature and Battery Physical Spacing....................................................................... 12

3.1.7. Insulating Battery Enclosure in Cold Temperatures.......................................................... 12

3.1.8. Battery Interconnect Cabling ............................................................................................ 12

3.1.9. Digital Voltmeters.............................................................................................................. 13

3.1.10. Environmental Conditions for Batteries ........................................................................ 13

3.2. Installation................................................................................................................................ 13

3.2.1. Configurations................................................................................................................... 13

3.2.2. Bolt Tightening .................................................................................................................. 14

4. Operation......................................................................................................................................... 15

4.1.1. Configuring Charge Controller & Inverter Voltage Set-points........................................... 15

4.1.2. Disable Equalization .......................................................................................................... 15

4.1.3. “Gel/Sealed Battery” Settings........................................................................................... 16

4.1.4. Energize Your Inverter First ............................................................................................... 16

4.1.5. Self-Protection Mode by the BMS..................................................................................... 16

4.1.6. Charge Rate ....................................................................................................................... 16

4.1.7. Temperature & BMS Self-Protection................................................................................. 16