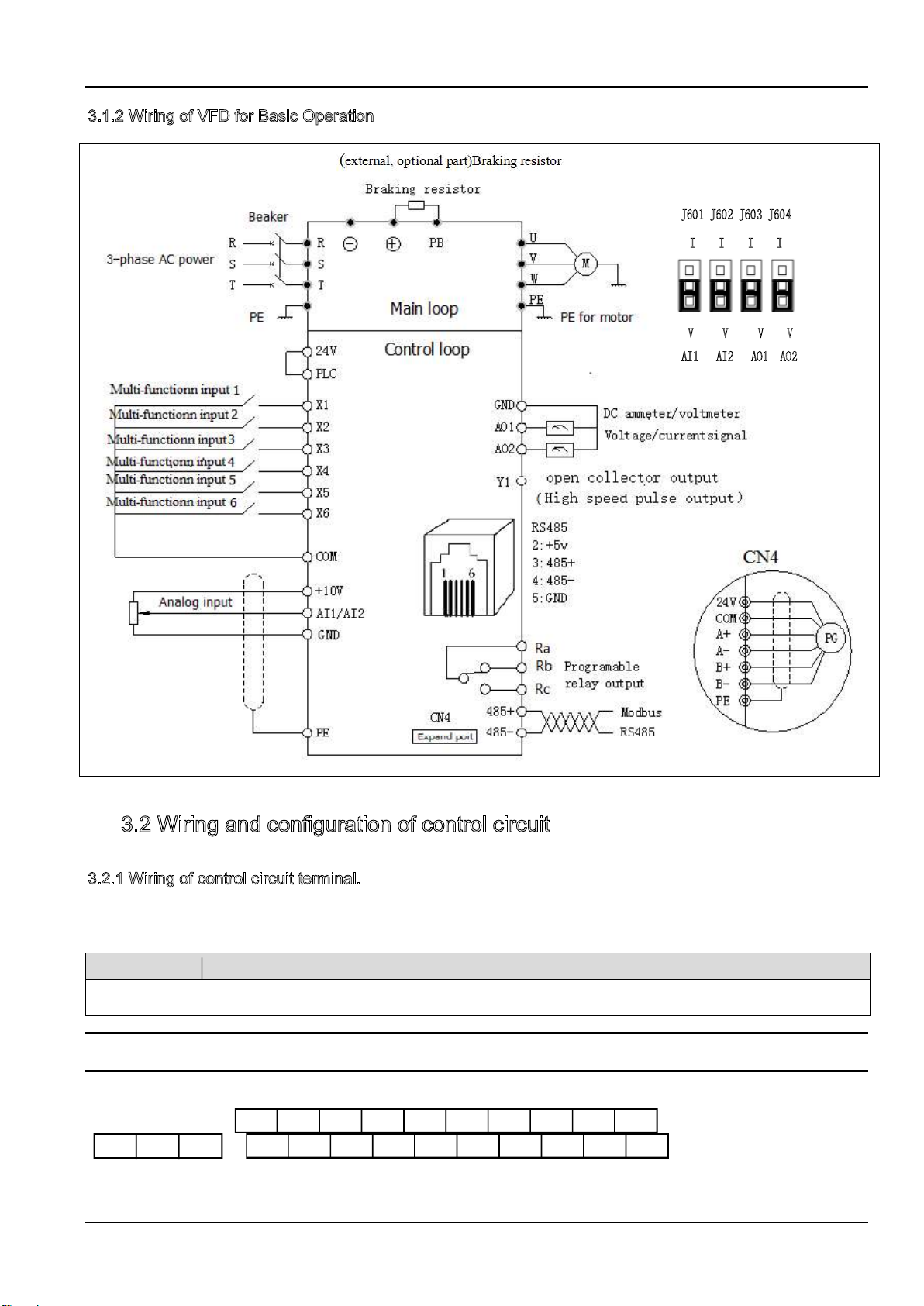

Chapter 3 Wiring Guide of VFD

47

Refer to table 3-3 for description of each terminal

Table 3-3 function list of each list

Category

Terminals

Name Function description Specification

Shield Shielded PE

PE terminal connected to shielding layer. 485

communication cable, Analog signal cable,

motor power cable shield can be connected to

this terminal here

Connected to PE terminal of main

loop inside

Power

supply

+10 +10V Power

supply Provide +10V power supply Maximum current output is5mA

GND +10V GND of

Power supply GND for analog signal and 10V power supply Isolated from COM and CME

inside

Analog

input

AI1 Signal-

input AI1

Can accept analog voltage or current input,

jumper AI1 can select voltage or current input

mode.(Reference ground. GND)

Input voltage range.-10V

10V(Input impedance

Input current range.0mA 20

mA,Resolution.1/2000(Need

jumper)

AI2 Signal-

input AI2

Can accept analog voltage or current input,

jumper AI2 can select voltage or current input

mode.(Reference ground. GND)

Analog

output

AO1 Analog

output 1

Providing analog voltage or current output, they

are selected by the jumper AO1. The default

setting is output voltage, refer to the function

code A6.28 for detail.(Reference ground. GND)

Voltage output range.0V 10V

Current output range.0/4 20mA

AO2 Analog

output 2

Providing analog voltage or current output, they

are selected by the jumper AO2. The default

setting is output voltage, refer to the function

code A6.29 for detail.(Reference ground.GND)

Voltage output range.0V

10VCurrent output range.0/4

20mA

Communi

-cation

RS485+ RS485

port

485+ StandardRS-485communication

port, please use twisted-

or shielded cable.

RS485- 485-

Multi-

function

input

terminal

X1 Multi-function

input terminal 1

Can be defined as multi-

terminal.

(Refer to the A6 group, form A6.00 to A6.06)

Optocoupler isolation input

Maximum frequency input of

X1 X5.200Hz

Maximum input frequency of

X6.100kHz

Input voltage range.2 30v

X2 Multi-function

input terminal 2

X3 Multi-function

input terminal 3

X4 Multi-function

input terminal 4

X5 Multi-function

input terminal 5

X6 Multi-function

input terminal 6

+24V

X1

PL

C

V

CO

M

24

V