OPERATING SUPPORT BAR

Preparing Work Area

Caution: Before using the Engine Leveller, it is important to prepare work area properly. Follow this procedure each time

the Leveller is used to help prevent property damage and or serious injury.

1. Thoroughly inspect Engine Leveller for damage or wear before each use. Briefly test operation of unloaded Leveller before

using to support any load. If Leveller is damaged or is malfunctioning DO NOT SUPPORT ANY LOAD until the problem is

corrected.

2. Consult vehicle owner’s manual for safety precautions, engine weight, and location of support areas on engine. The safe

working load limit of this Engine Leveller is between 680kg. NEVER EXCEED THE SAFE WORKING LOAD LIMIT

OF THE ENGINE LEVELLER.

3. Loads which are allowed to swing or move of centre can exert a force greater then the weight of the object lifted. Make

sure load is secured and not able to move from the vertical lifting line.

4. Clear children and others from work area before commencing work. Another adult should be nearby for extra safety and

assistance but must be clear of vehicle as it is worked on.

5. Clear obstructions from work area. Working in tight or cluttered work areas is dangerous.

6. Be sure vehicle is on solid, level ground such as paved or concrete driveway or garage floor. Uneven or sloped surfaces

create hazardous working conditions and dangerously impeded the function of the support bar.

7. With vehicle in proper position, set vehicle’s parking brake or emergency brake and put gearshift in park (manual

transmissions should be placed in lowest gear). TURN VEHICLE IGNITION OFF AND TO THE “LOCK” POSITION making

sure steering wheel locks.

8. Chock all wheels of vehicle to prevent vehicle rolling. Using wedge-shaped blocks that tyre cannot roll over, position one

chock tight against the tyre in both forward and reverse rolling paths.

Operation

Caution: Follow all instructions and precautions below and those of the lifting device.

1. NEVER work under an engine supported by a lifting device. Never place and part of you body under an engine

supported by am engine leveller.

2. With Engine Leveller properly assembled, place the Engine Leveller onto the lifting device making sure instruction from

both devices are adhered too.

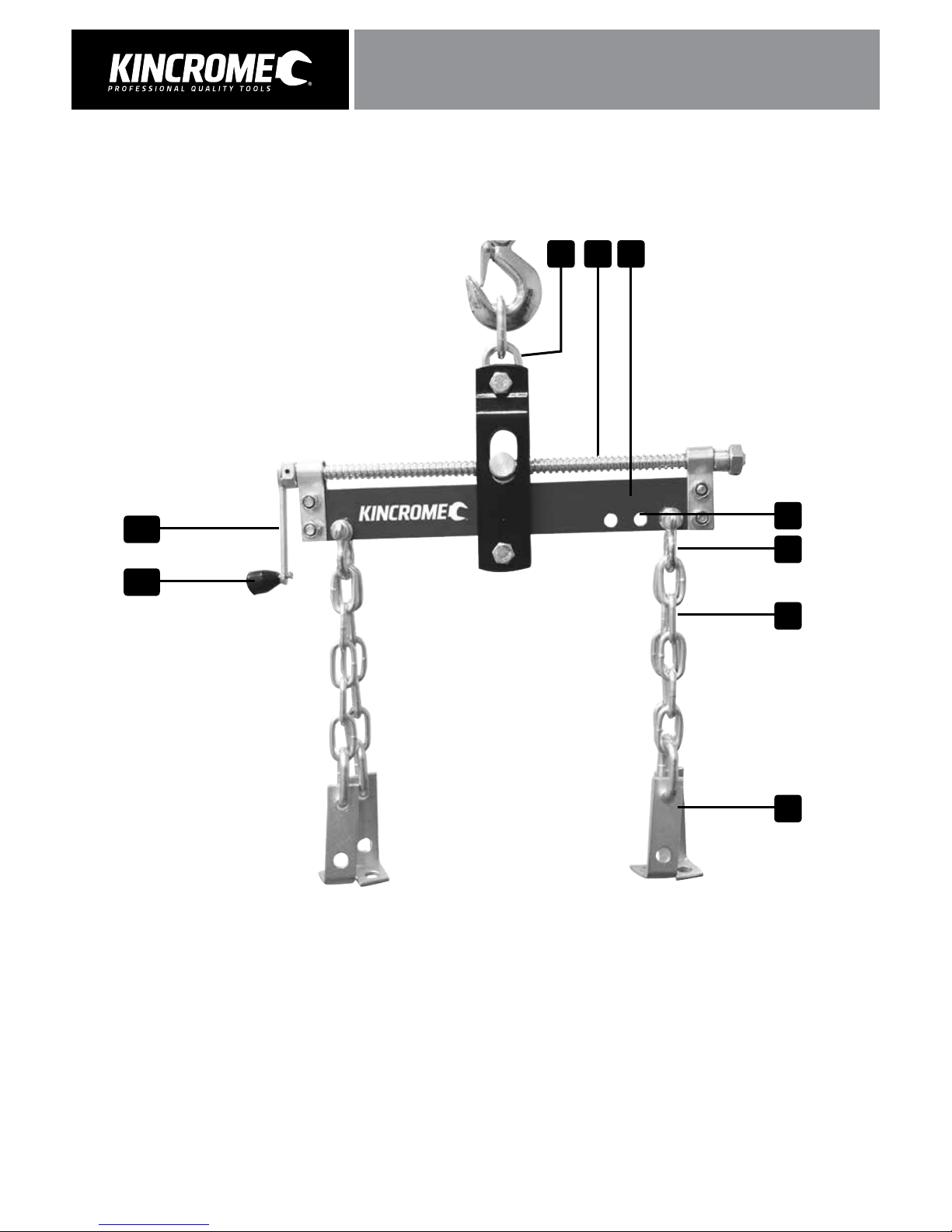

3. Attach Chains (6) (with or without Support Brackets (7) to the engine, making sure the device is securely attached to the

engine and is suitably rated to hold the weight.

4. Slowly lift load via lifting device until it just about to bear load, check the Engine Leveller is securely connect to the engine

and the Engine Leveller appears level.

5. Inspect engine securing device making sure it is properly attached to the engine.

6. Remove bolts from the engine mounts. Slight adjustment of the Engine Leveller may be required by cranking the Handle

(8) to maintain engine position after other fasteners are loosened or removed.

7. Never leave an engine suspended by an Engine Leveller and other lifting device – the product is intended for short term

use during repair. As soon as is practicable engine should be transfered to an Engine Stand and Engine Leveller removed.