TABLE OF CONTENTS

1.0 GENERAL INFORMATION

About this Manual................................................................................................................................. 3

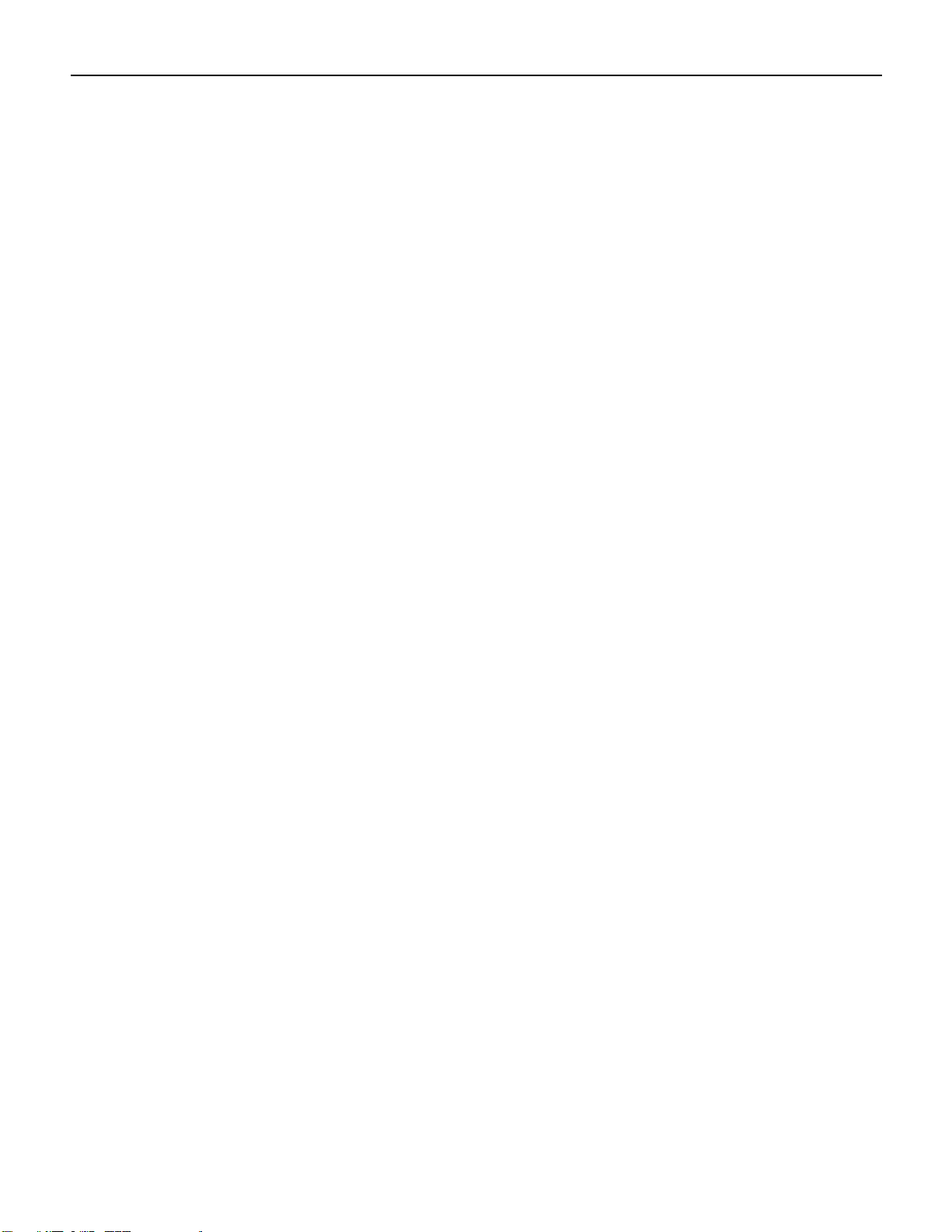

The Compact Commercial Softener ..................................................................................................... 5

System Sizing....................................................................................................................................... 5

Flow Rate Sizing................................................................................................................................... 6

Specifications ....................................................................................................................................... 7

2.0 OPERATING SPECIFICATIONS

System Operation................................................................................................................................. 8

Disc Selection....................................................................................................................................... 9

Kinetico Valve Operation.................................................................................................................... 10

Water Meter Disc ......................................................................................................................... 10

Regeneration Pawls..................................................................................................................... 10

Jet Regeneration.......................................................................................................................... 10

Control Disc.................................................................................................................................. 10

Control Disc Indicator................................................................................................................... 11

Lower Valving Sections................................................................................................................ 11

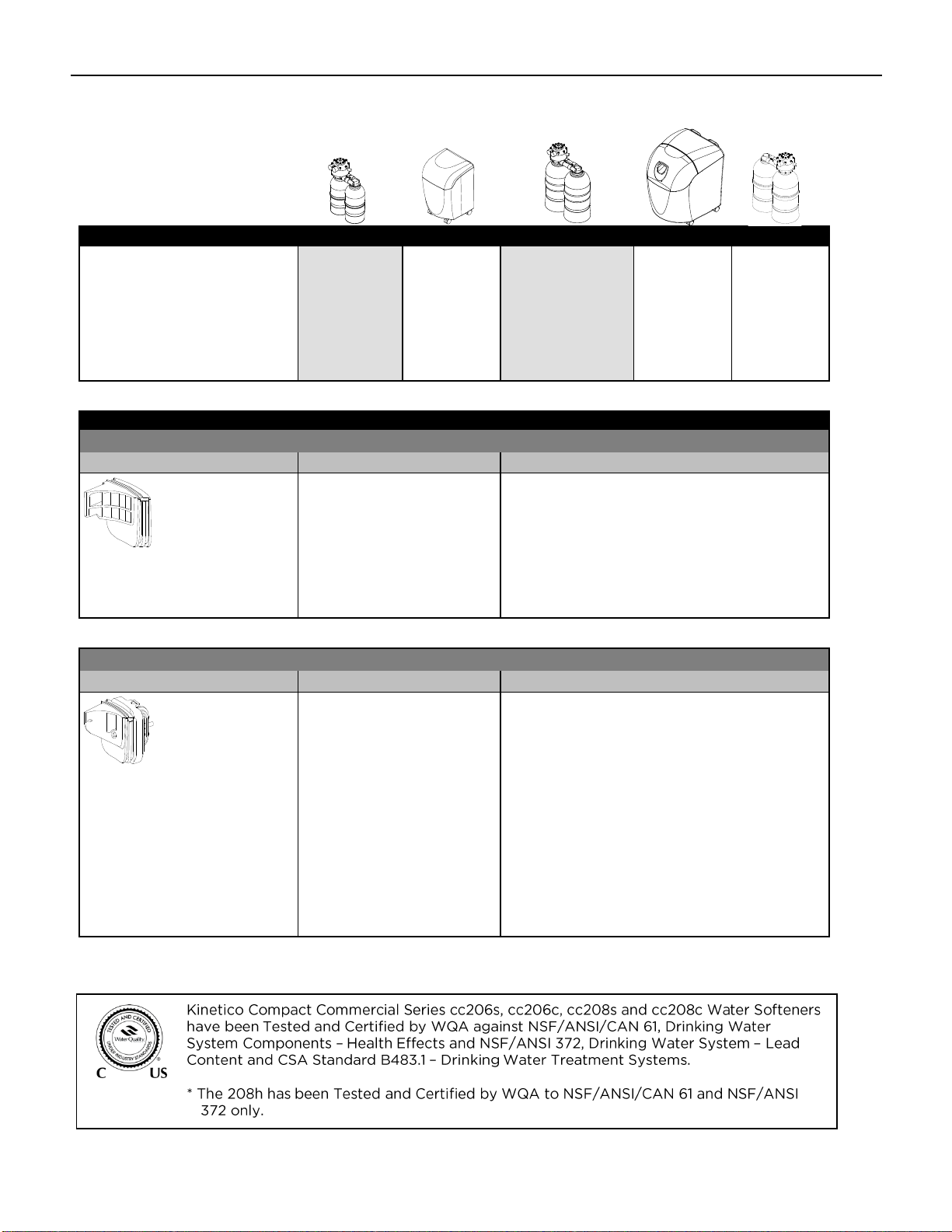

Tank Components.............................................................................................................................. 12

3.0 INSTALLATION

Getting Started ................................................................................................................................... 13

Pre-installation Review....................................................................................................................... 13

KineticoPRO Compact Commercial Softener Installation................................................................... 14

4.0 TROUBLESHOOTING

Ten Steps to Determine the Problem ................................................................................................. 17

Hard Water......................................................................................................................................... 19

Frequent Regeneration....................................................................................................................... 20

High Salt Consumption....................................................................................................................... 20

Leaks.................................................................................................................................................. 20

Salty Treated Water............................................................................................................................ 21

Taste, Color & Odor............................................................................................................................ 21

Iron Bleed-through.............................................................................................................................. 22

Water Running to Drain...................................................................................................................... 22

Pressure loss...................................................................................................................................... 23

Equipment Noise................................................................................................................................ 23

Units Stuck in Cycle............................................................................................................................ 23

5.0 PARTS................................................................................................................................................... 24