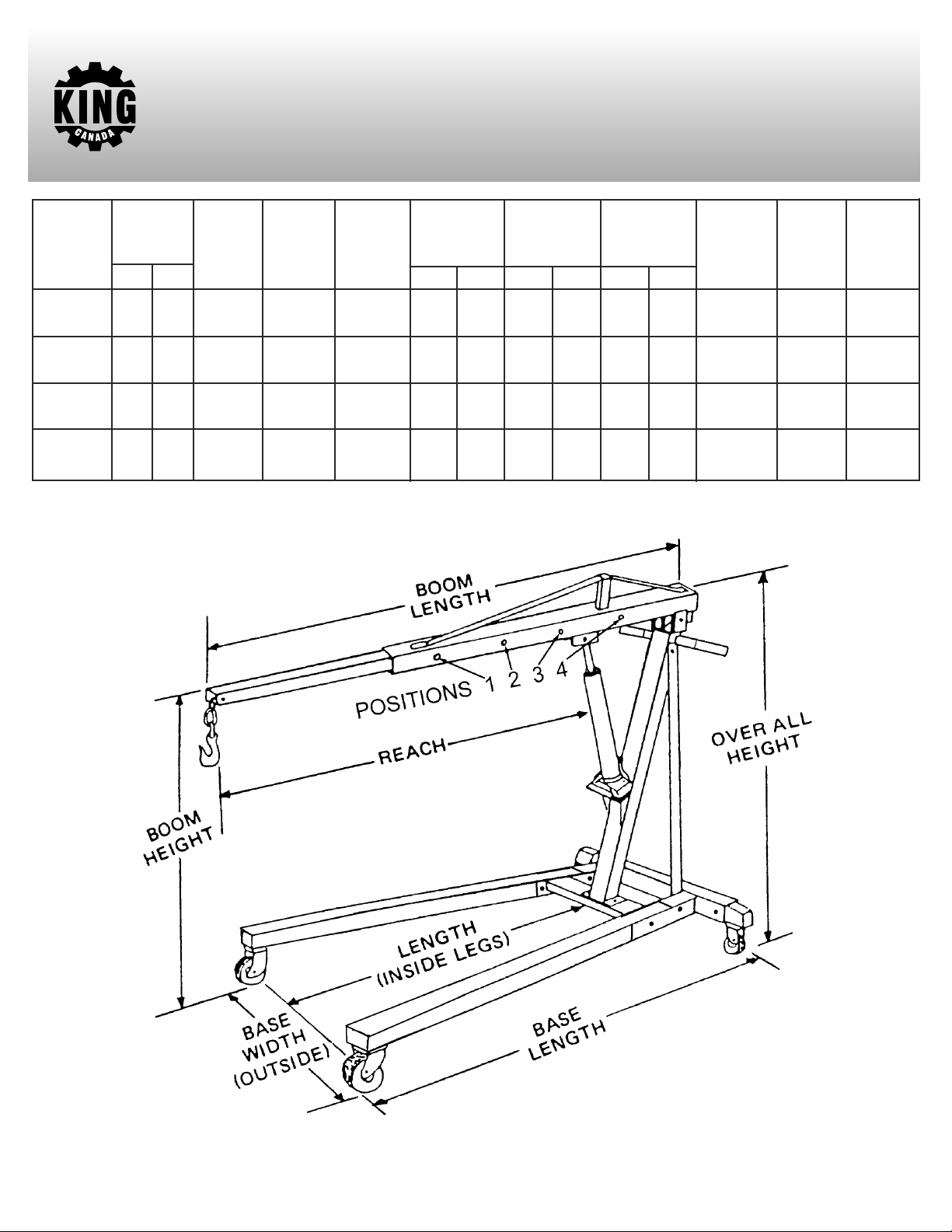

ASSEMBL

Note: Refer to parts diagram for index numbers found in parenthesis (#):

1. Install two large wheels (#1) to the front legs (#11) and two large wheels (#1) to the frame base (#4) using four hex. bolts (#3) and hex. nuts

(#2) for each wheel. Install two smaller wheels (#10) to the frame base (#4) using four countersunk head screws (#9) and hex. nuts (#2).

2. Attach front legs (#11) to the frame base (#4) using all four hitch pins (#7) and hitch pin clips (#8). n each leg, insert 1 pin through frame

base and front leg at rear hole. The hitch pin serves as a pivot pin and remains in the hole permanently. Insert a second hitch pin in the most

forward hole through the frame base and front leg. This locks the legs in the down position.

3. Insert hitch pin clips (#8) through hitch pins (#7) to secure in place.

4. Attach the main support post (#18) to the frame base (#4) using two M14 x 95 hex. bolts (#6) and hex. nuts (#5).

5. Attach both support braces (#16) to the top of the main support post (#18) using a M14 x 95 hex. bolt (#6) and hex. nut (#5).

6. Connect the support braces (#16) to the frame base (#4) using two M14 x 95 hex. bolts (#6) and hex. nuts (#5).

7. Connect the bottom of the hydraulic ram assembly (#15) to the main support post (#18) using a M16 x 85 hex. bolt (#13) and hex. nut (#17).

8. Connect the boom (#20) to the main support post (#18) using a M16 x 110 hex. bolt (#19) and hex. nut (#17).

9. While another person supports the boom (#20) up attach the top of the hydraulic ram assembly (#15) to the boom with a M16 x 85 hex. bolt

(#13) and hex. nut (#17).

10. Slide the boom extension (#21) into the boom (#20) with the slot for the hook and chain assembly (#23) facing down. Secure boom extension

with M14 x 85 hex. bolt (#27) and hex. nut (#5).

11. Install chain and hook assembly (#23) using a M14 x 75 hex. bolt (#22) and hex. nut (#5).

12. Install handle assembly (#24) to the rear of the support post (#18) using four hex. bolts (#25).

13. Install all five end caps (#26) using a rubber mallet.

14. Make sure all hardware is tight.

OPERATION

1. Load to be lifted must be securely attached with a sling or chain of adequate size and strength. Before lifting the load, be sure the load

cannot twist or fall.

2. Move crane into position. Legs must be in down position and locked into place. Never use crane with the legs in the upright position.

3. Close hydraulic valve at the base of ram by turning clockwise until tight.

4. Place sling or chain in center of hook.

5. Slowly raise the load to desired height by inserting ram handle and pumping handle.

6. Move load to desired location by rolling crane assembly. Use caution so that load does not swing or rotate.

7. Slowly lower load to desired location by inserting ram handle onto valve at base of the ram and slowly turning counterclockwise. Do not lower

too quickly.

MAINTENANCE

Important: Use only a good grade hydraulic jack oil. Avoid mixing different types of fluid and NEVER use brake fluid, turbine oil, transmission

fluid, motor oil or glycerin. Improper fluid can cause failure of the jack and the potential for sudden and immediate loss of load.

Adding oil

1. With jack fully lowered and handle sleeve fully depressed, remove oil filler plug.

2. Fill with hydraulic oil until just below the rim of the oil filler plug hole. Reinstall the oil filler plug.

Changing oil

For best performance and longest life, replace the complete hydraulic oil supply at least once per year.

1. With jack fully lowered and handle sleeve fully depressed, remove jack from crane. With jack in it’s upright, level position, remove oil filler plug.

2. Lay the jack on its side and drain the oil into a suitable container.

Note: Dispose of hydraulic oil in accordance with local regulations.

3. Set jack in its upright, level position.

4. Fill with hydraulic oil until just below the rim of the oil filler plug hole. Reinstall the oil filler plug.

Lubrication

A periodic coating of light lubricating oil to pivot points will help to prevent rust and assure that casters and other parts move freely.

Cleaning

Periodically check the pump ram for signs of rust or corrosion. Clean as needed and wipe with an oily cloth.

ASSEMBL , OPERATION

& MAINTENANCE