5

• Onlypersonswhohavebeeninstructedinthe

use of vertical ladder and fall protection systems

may use the H-50 fall protection system and the

SPL-50-PRO fall arrester. The user of the fall ar-

rest system must be physically and mentally ca-

pable of movement using the respective equip-

ment. Safety in normal or emergency conditions

must not be compromised.

• Thecontractororoperatorofaplantmustputin

place a plan which covers all possible emergen-

cies that might arise when using the fall arrest

system and outlines the measures required for

rescuing personnel.

• Theaccidentpreventionregulations

DGUV regulation 1 and

DGUV rules 112-198/199 (Germany)

must be respected.

Testing must adhere to the respective national

operating and testing regulations.

• Nochangesoradditionsmaybemadetothe

H-50 fall protection system without the pri-

or written consent of Hailo. Repairs may only be

carried out using original parts and in accor-

dance with Hailo‘s instructions.

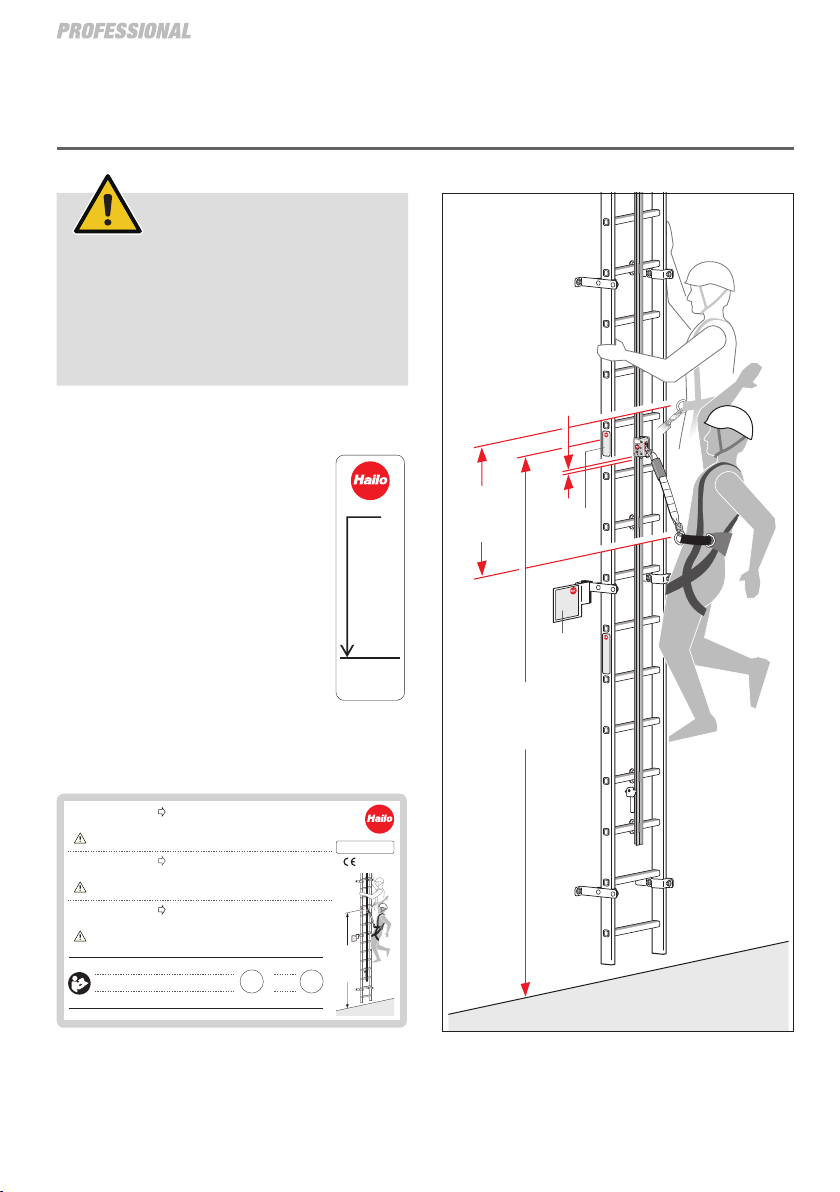

• TheSPL-50-PROfallarresterisdesignedforuse

in temperatures ranging from - 40°C to + 50°C.

The safe function of the fall arrester can be im-

paired e.g. by extreme climatic conditions, che-

micals, contamination or mechanical influences

(sharp edges, oil, ice, etc.). Use in this case is

prohibited.

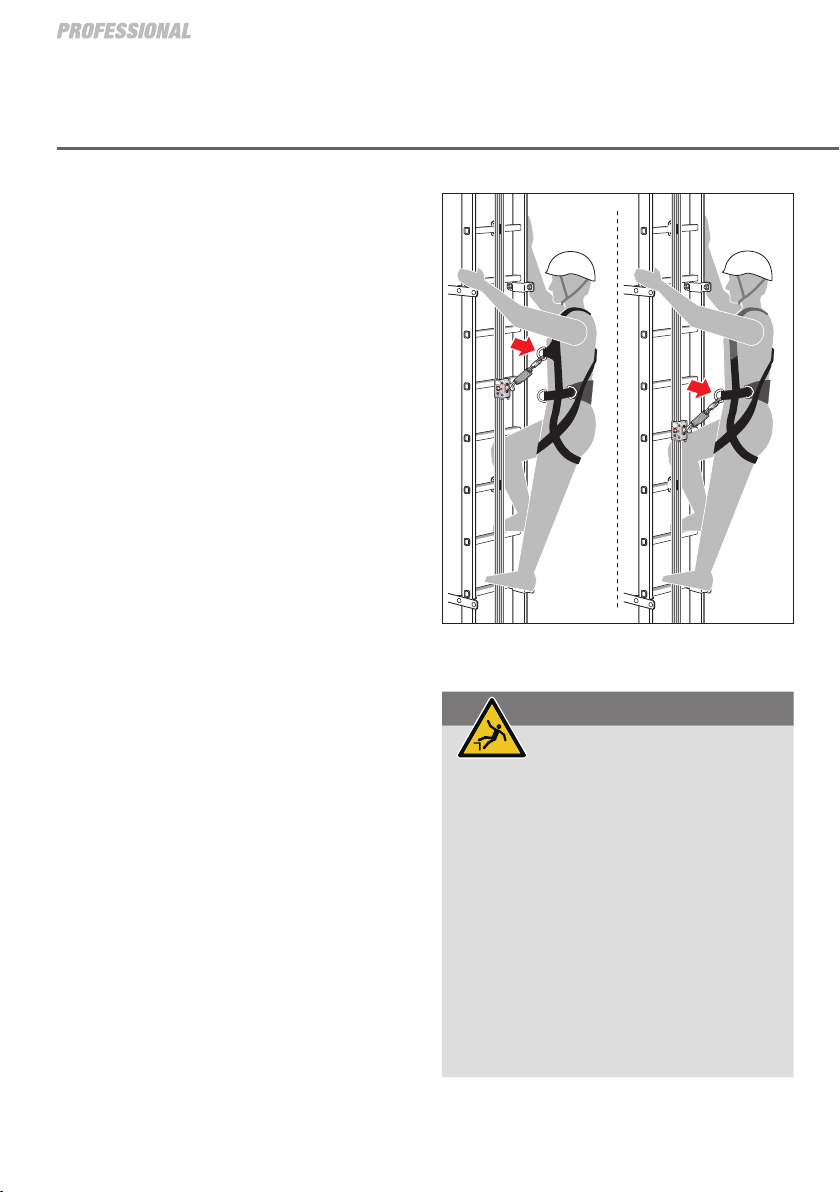

• Nomorethan5personsmayusethefallarrest

system at the same time. The distance between

individual users must be at least 6 m.

• TheH-50fallarrestsystemisdesignedasafall

safety when using rung ladders and pole clim-

bers, both above ground and below ground.

It is designed for a safe ascent and descent of

service personnel to workstations at higher or lo-

wer levels.

• TheSPL-50-PROfallarresterisapprovedexclu-

sively for securing persons with a total weight

(body weight of the user including clothing and

equipment) of 50 - 136 kg.

The use of climbing aids is prohibited unless the

safe usability of the combination in question has

been explicitly demonstrated.

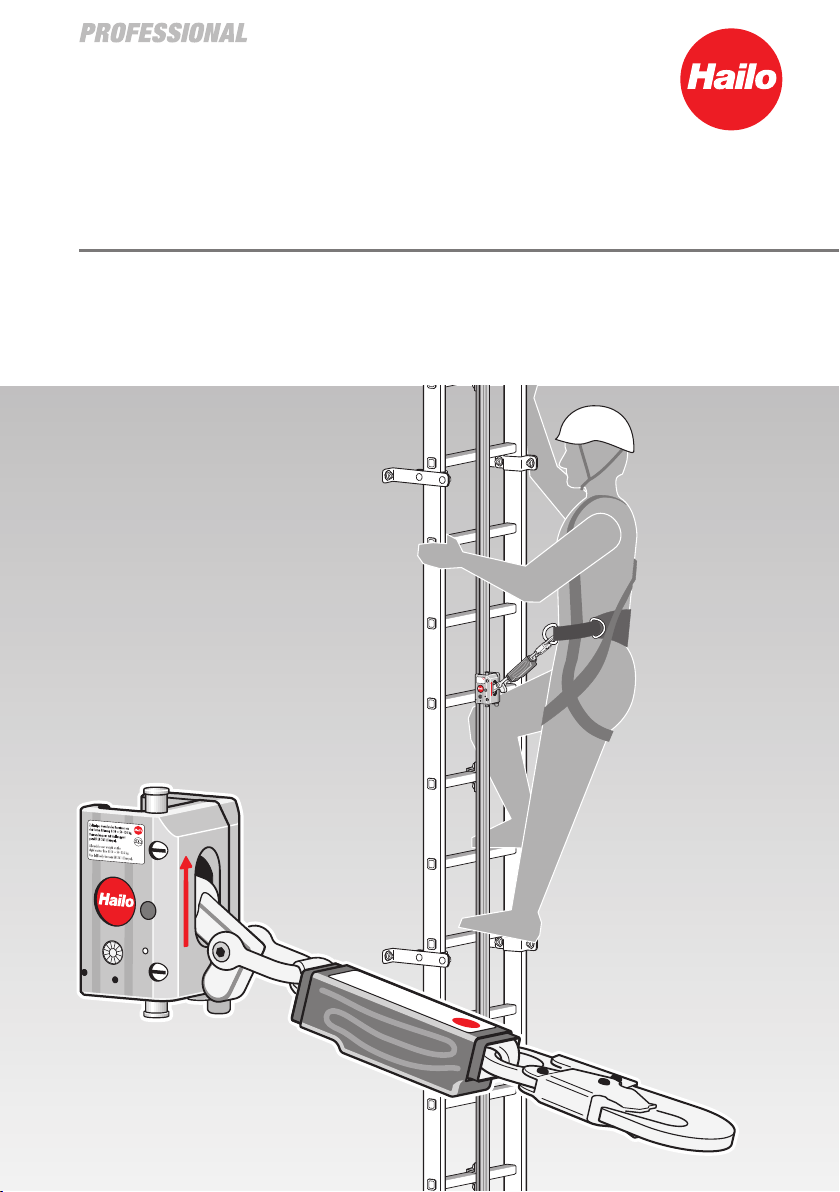

• UsersoftheH-50fallarrestsystem,alongwith

their fall safety personal protective equipment

(PPEgA), connect to the fall arrester, which runs

along the entire length of the ladder system.

(see page 6).

• Thefallprotectionsystemmayonlybeused

within the operating conditions described in this

information booklet.

Any other use (e.g. as workplace positioning or

as an anchor point) is prohibited and can lead to

failure of the safety system in the event of a fall.

No liability is assumed for personal injury or pro-

perty damage resulting from violations of the

provisions outlined in this booklet or from failure

to comply with the safety instructions.

3. Intended use

4. Safety instrucons