SAS/op/proc/forks/op manuals/Ex/EXTREME MANUAL v13.pub 2/24/2019 Page 4 © 2014-2019 S.A.S. of Luxemburg, LLC.

S.A.S. of Luxemburg, LLC. 133 Center Drive Hwy 54, PO Box 260, Luxemburg, WI 54217 USA

Phone: 920-845-2307 1-877-SAS-FORK Fax: 920-845-2309 Web: www.sasforks.com

INTRODUCTION LETTER (PAGE 4)

SAS™ EXTREME™ AUTO PROCESSOR

TO THE OWNERS, MANAGERS, AND OPERATORS OF EXCAVATORS

EQUIPPED WITH SAS™ EXTREME™ AUTO PROCESSOR

Safety is the most important issue in the workplace. Observing safety guidelines, equipment

capacities and using common sense will provide a work environment that is safe and efficient

for employees, management and customers. It is important that you and your operators read

and understand the information included in this manual prior to use of this equipment.

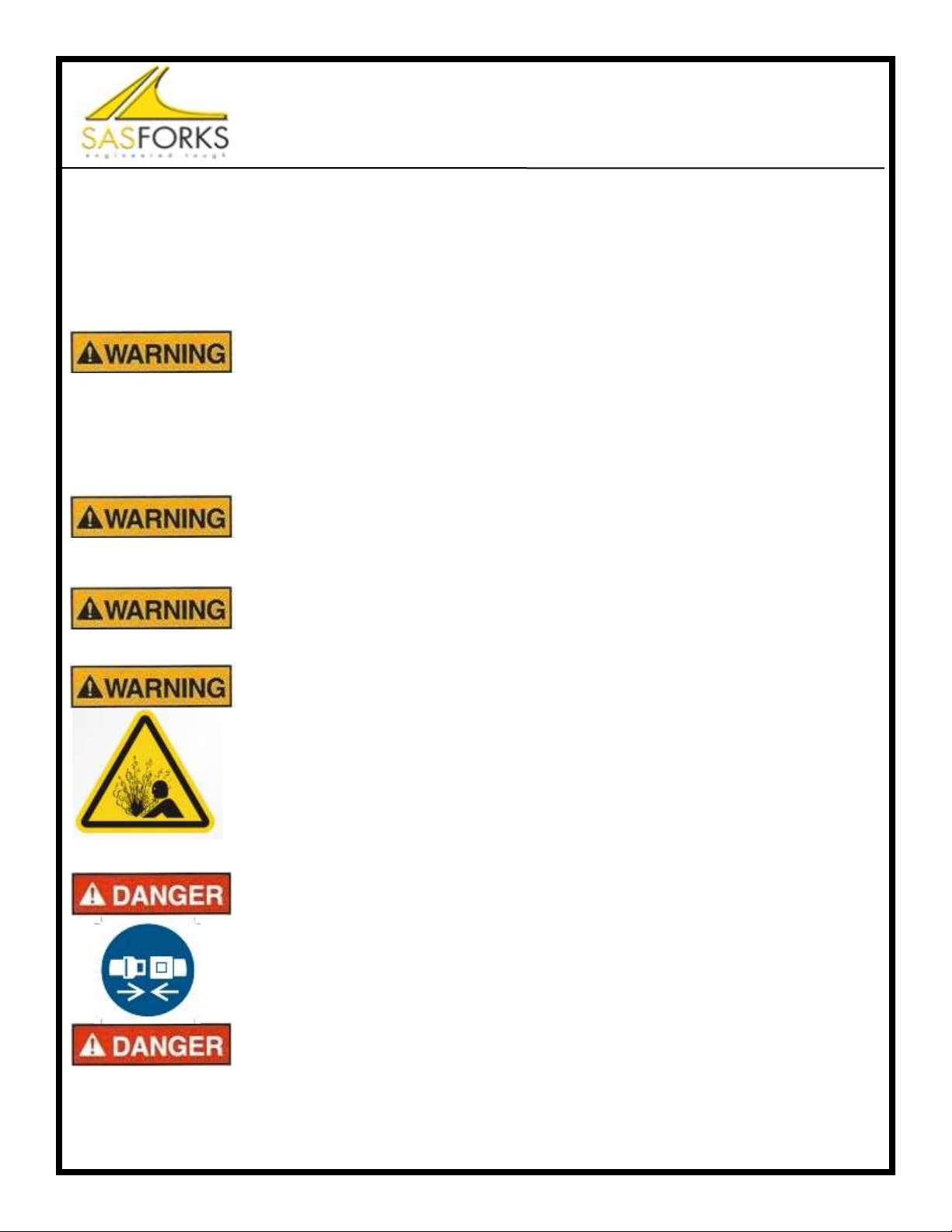

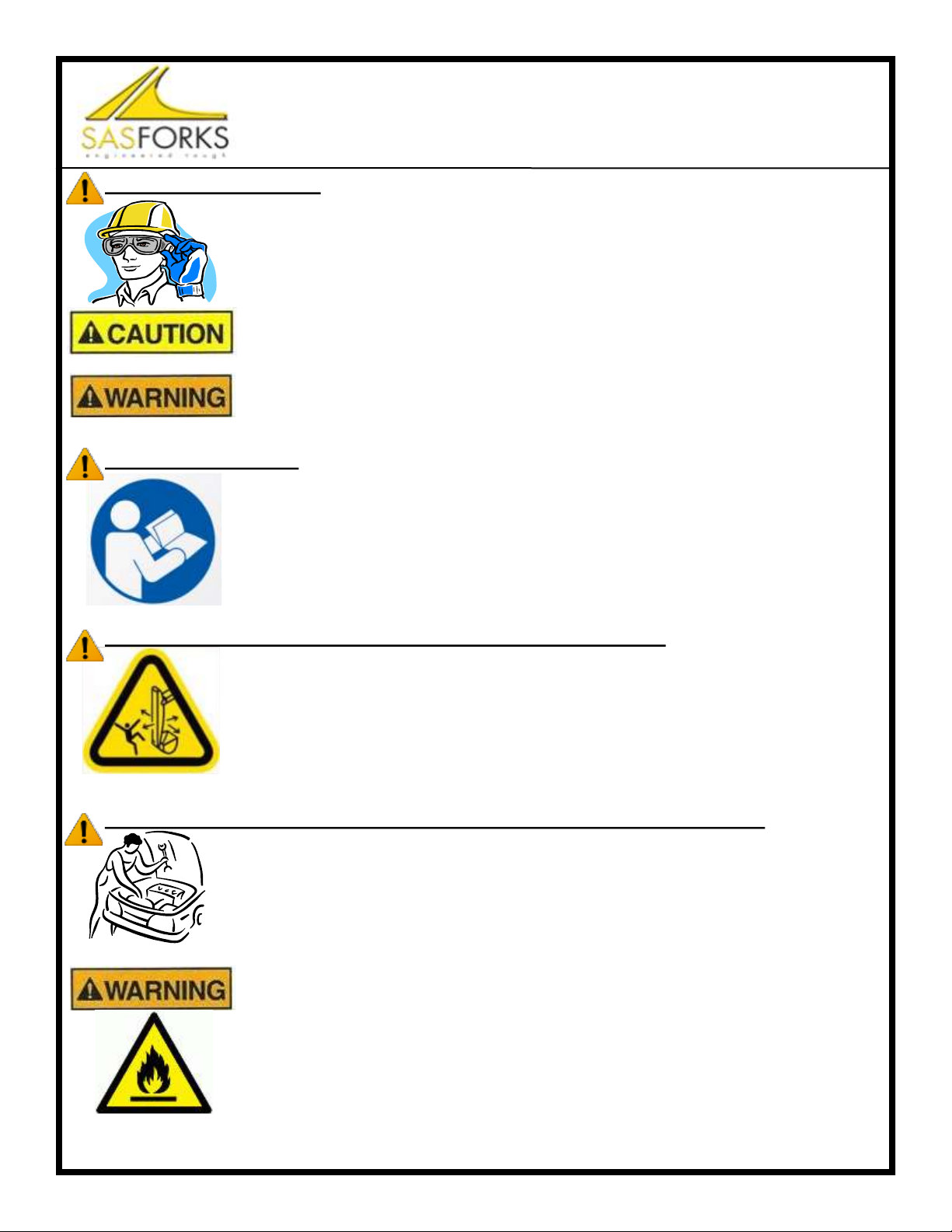

Safety warnings are highlighted through out this manual. Understanding the significance of

these symbols is important. The following is a definition of each symbol you will encounter in

this manual:

The Symbol is intended to draw your attention to important safety

information, hazard or precaution.

The Danger Symbol indicates a hazardous situation that if not avoided will

result in serious injury or death

The Warning Symbol indicates a hazardous situation that if not avoided

could result in serious injury or death

The Caution Symbol indicates a hazardous situation that if not avoided

could result in minor injury or potential property damage

The Notice Symbol indicates worst credible severity of harm is property

damage.

The following information presented in this Operator Manual for SAS FORKS™ is intended to

be a guide only, and is not meant to encompass all issues that may need to be addressed for

your particular type of business operation.

If you encounter additional information that would be helpful to us, or others, please contact us.

Thank you for your business,

SAS Ltd. Phone: Email:

133 Center Dr Hwy 54 · PO Box 260 International: 00+1+920-845-2198

LUXEMBURG, WI 54217 U.S.A.

·Proprietary Rights: All designs and other proprietary rights provided by S.A.S. of Luxemburg, LLC. to

Buyer are to remain the property of S.A.S. of Luxemburg, LLC., and Buyer shall honor all proprietary legends.

Notice: The SAS FORKS™, this operator manual, www.sasforks.com web site, the pictures, content, designs,

forks, and likeness of such, are property of S.A.S. of Luxemburg, LLC. and are protected under all applicable

Copyright, Trade Mark, Trade Dress, Patents and/or Pending Patent.

USA Patents: D672,369 ;D704,752 ; D740,861; D779,564; 9,815,128; D779,565; 9,211,832; 9,414,704; D747,170

No information, pictures, designs, products, features, or forks may be duplicated in part, entirety, or in likeness.