OPERATING RECOMMENDATIONS

The interior of this appliance will get very hot during operation. ALWAYS use an oven glove

(preferably one which covers the wrist and lower arm as well) when operating the baker or removing

potatoes from it.

Take particular care when opening the oven door, the built-up steam and heat inside will escape as soon

as the door is opened and could cause injury if you are standing too close.

Handle baked potatoes carefully, occasionally they may burst in the oven or whilst being handled.

Avoid opening the main oven door unnecessarily as this will cause heat loss and lengthen the cooking

time, as the oven recovers heat. NB: Use of this this product may increase ambient room temperature.

Do not turn the thermostat control up to its full setting, as this will invariably burn the outside of the

potatoes before the inside is cooked. High or Full setting will not necessarily cook the potatoes quicker -

moderate heat for longer is preferable.

Our figures are based on 8oz potatoes, and much larger ones will require longer baking. When using

larger potatoes adjust the oven capacity accordingly. Taking the trays out and positioning the potatoes

before loading will enable you to gain the maximum capacity from your baker, but always remember to

use a heat pad when placing hot wire trays directly onto a work surface.

Always use best practise and take all reasonable precautions to avoid accidents when using this oven.

INSTRUCTIONS FOR USE

Take out the wire trays and position the potatoes on them ready for loading.

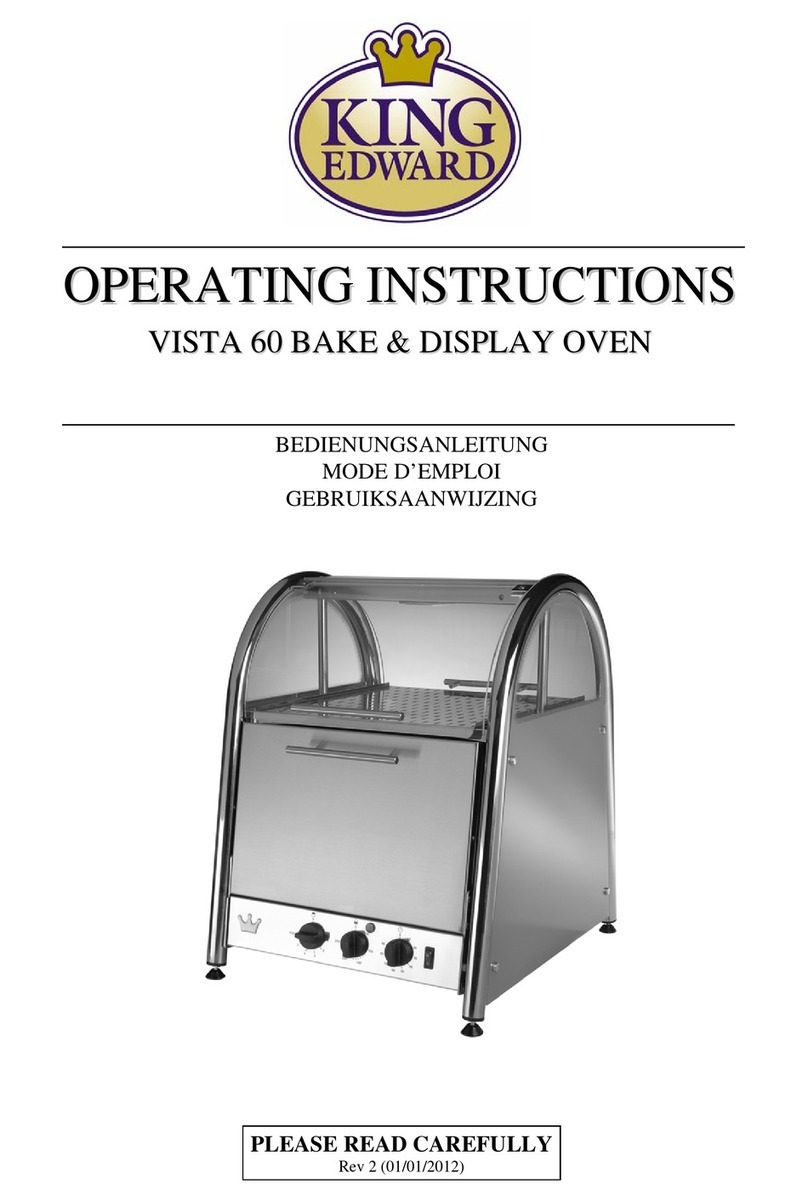

Plug the oven in at the socket, turn on the ‘Fan on’ rocker switch in the control panel, this will turn the

fan motor on and also the display lights.

Turn the thermostat knob on the control panel to the temperature required. For jacket potatoes we

recommend 190 - 200°C. At this stage the neon light will come on to show that the oven is heating up.

When the thermostat neon goes out, the oven has reached temperature. You can then load the prepared

trays of potatoes. At this stage you may use the timer by setting it to the desired cooking time. The red

neon will then go off when the bell rings at the end of the cooking period; but PLEASE NOTE - the

oven will not automatically turn off!

When cooked sufficiently, the potatoes will feel soft when gently squeezed; they can then be transferred

to the top display area. To maintain adequate storage temperature in the top display area, the main oven

must be left on at normal operating temperature (190 - 200°C).

If you intend to cook products other than potatoes, adjust the temperature and cooking times according

to the product’s cooking instructions. It is important to remember this is a fan assisted oven with

reduced cooking times.

INSTALLATION INSTRUCTIONS

We recommend that wherever possible, the baker is sited near adequate extraction / ventilation to assist

with the disposal of steam.

Make sure that the mains flex cannot come into contact with hot surfaces and that it is adjusted to the

required length by a qualified person upon installation. Do not push excess flex under the baker.

Do not position the baker near to the edge of a counter or work surface, where staff or customers may

brush against it in passing.

Position the baker so that the electrical socket can be reached easily in the event that the baker needs to

be disconnected from the electric supply.