Page 2

The information contained in this manual was accurate

at the time of release. Specifications are subject to

change without notice.

Warranty - All King Engineering products are

guaranteed to be free from defects in material and

workmanship for one year from the date of purchase.

Any product or part found to be defective under normal

use within one year of purchase will be repaired or

replaced at no charge if returned to the company at

Ann Arbor, Michigan within ten days of discovery of

the defect. No other warranties, whether expressed,

implied or statutory, including the warranties of fitness

for a particular purpose or merchantability, are given by

this agreement. The exclusive remedy for nonconformity

of these goods shall be repair and/or replacement of

the nonconforming goods or parts.

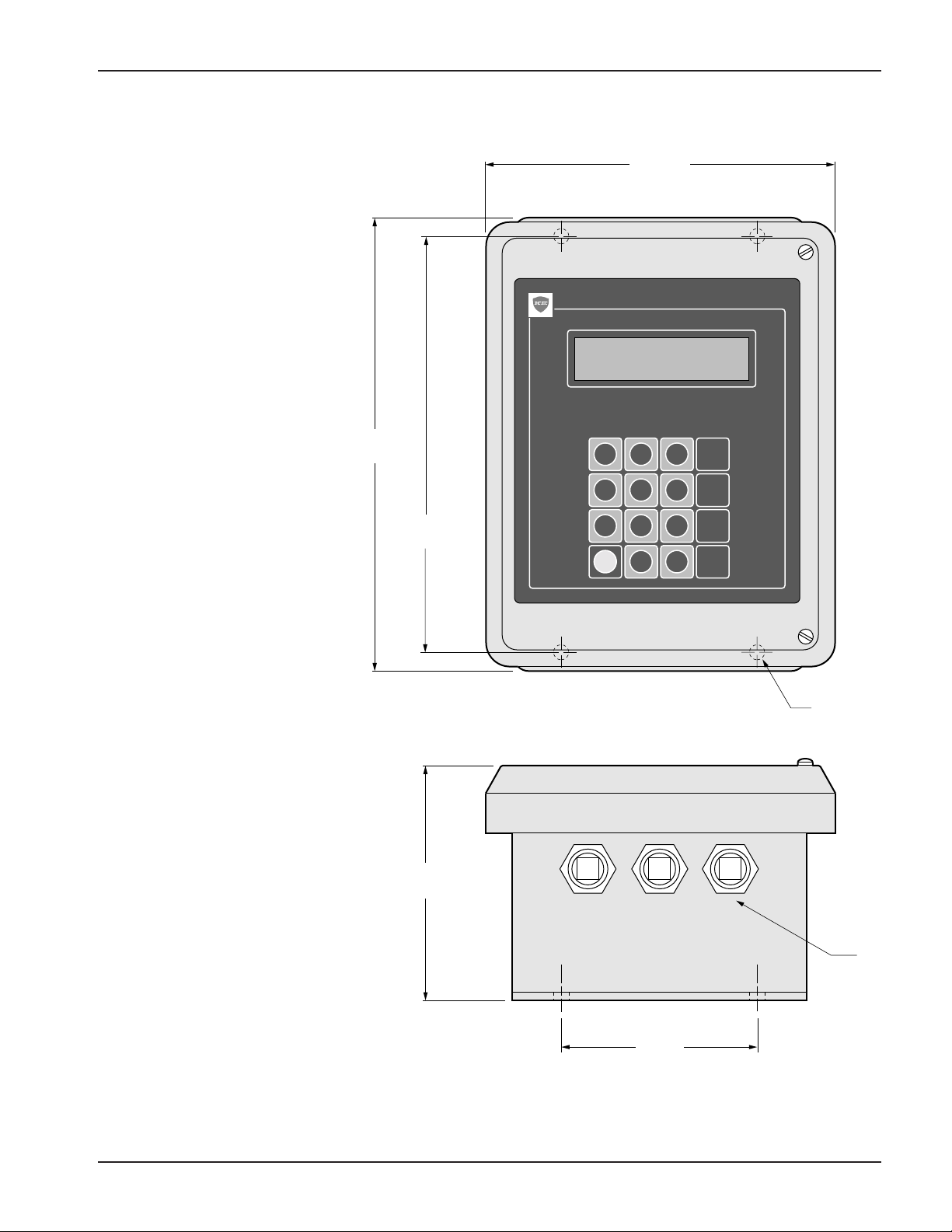

LevelPRO - Multiple Tank Level Processor EX-1803

Seller will not be liable for consequential damages

resulting from breach of this agreement. The term

“consequential damages” shall include but shall not

be limited to damage to all machines, equipment and

goods other than the goods sold hereby, interruption

of production, loss of profits, delays of any kind,

administrative expense and overhead.

©1997 King Engineering Corporation. All rights reserved.

®KING-GAGE and the KE emblem are registered trademarks and

LevelPRO is a trademark of King Engineering Corporation,

Ann Arbor, Michigan, U.S.A.

Specifications subject to change without notice.

Revisions:

(A) January, 1997 – Original Release

(B) July, 1997 – Revised with LED status and

communications sample response

(C) January, 1998 - 734 Area Code update

(D) March, 1998 - LevelPRO response (pg 12)