BioFicient 1-3

INSTALLATION MANUAL

45

SELF HELP

In order to minimize the need for dealing with emergency situaons we recommend that Treatment Plants have a Pre-service

Agreement Inspecon, and then is regularly serviced by us or an approved Service Engineers. Provided that your plant is

installed, operated correctly and serviced, you should not need to get into much – if any – self-help.

However, some of the most likely queson and answer situaons are listed below.

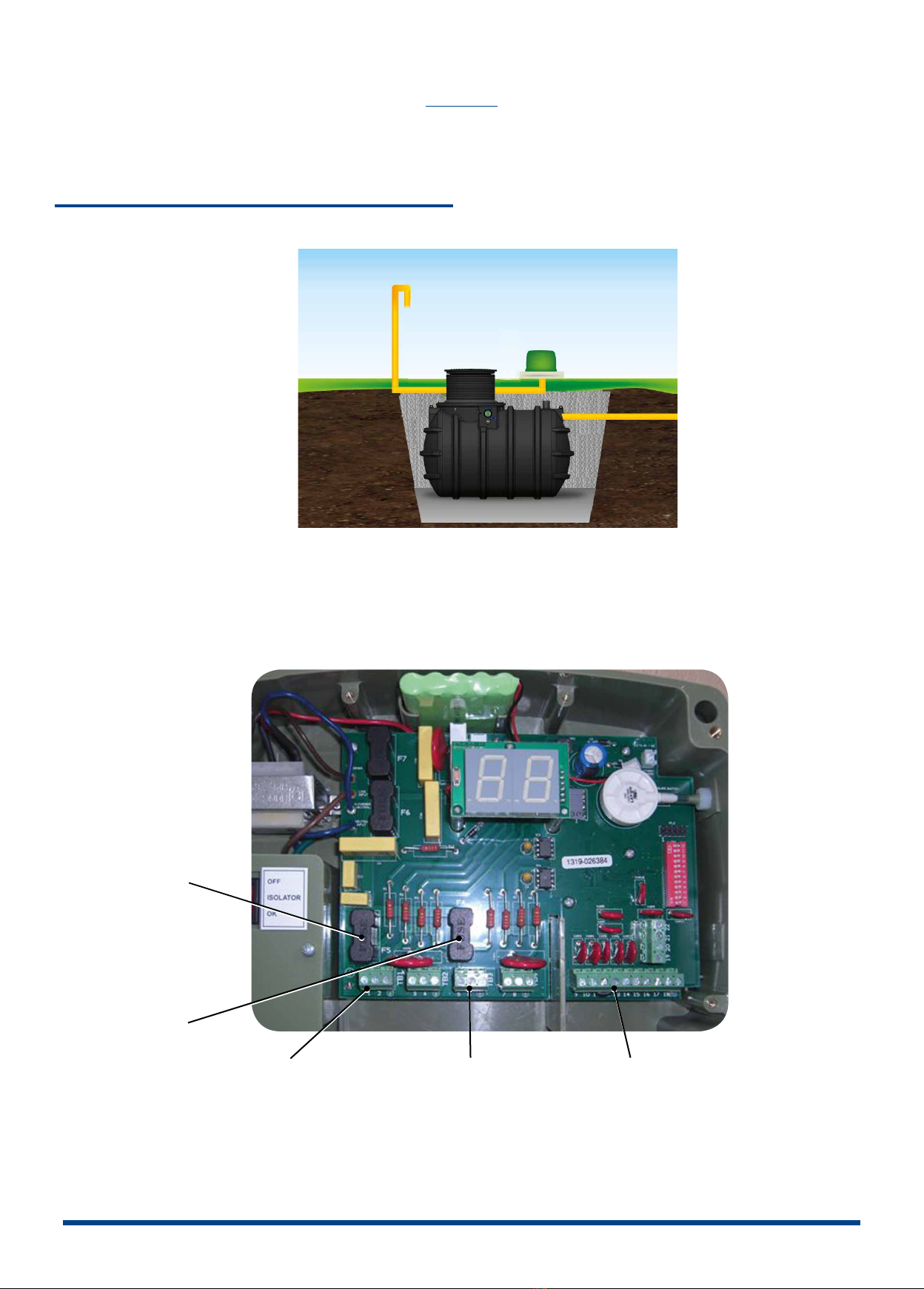

Blower

Blower Stopped:

• Check the unit is switched on, the incoming power supply

circuit and fuse.

Blower works but no water distribuon inside the plant:

• Check hose connecons.

• Check distributor heads.

• If the air li pipes are suspected to be blocked, call for service.

• Check regulang valve is not closed.

Plant ooding

• Check for blocked outlet system.

• If pumped outlet, check for pump operaon, check oats and

pump power supply.

Plant odour

• Check blower working.

• If blower working, plant probably needs desludging.

• Check vent circuit is clear.

• Check that the air duct entering the blower housing has

been sealed with foam.

DO’s

Do take out a service agreement and let the experts look aer your plant.

Do contact us for advice if you have any cause for concern.

DON’TS

Don’t pump feed the plant without reference to us.

Don’t use a waste disposal unit as you will be adding to the biological load, and your system may not be large enough to cope

with the waste. If you are unsure please refer to our sales team for guidance.

Don’t throw any medicines down the toilet.

Don’t empty large quanes of bleach or similar cleaning reagents into the system.

Don’t empty cooking oil or similar down the sink.

Don’t cover the plant with soil material or prevent access for service and desludging.

Don’t apply a hose or jet wash to the biological lter unless specically advised to.

Don’t try to enter the plant

Don’t put sanitary towels, inconnence pads, nappies, tampons or other non-biodegradable items’ down the toilet.