Piezoelectric Force Sensors, Ring Force Transducers

9001C_002-928e-12.20Page 2 Page 39001C_002-928e-12.20

Content

1. Introduction .................................................................................................................................4

2. Important instructions................................................................................................................5

2.1 For your safety....................................................................................................................5

2.2 Disposal instructions for electrical and electronic equipment .............................................6

2.3 Unpacking...........................................................................................................................6

2.4 Notes on handling the sensor.............................................................................................6

2.5 Tips on use of manual ........................................................................................................7

3. General.........................................................................................................................................8

3.1 Applications ........................................................................................................................8

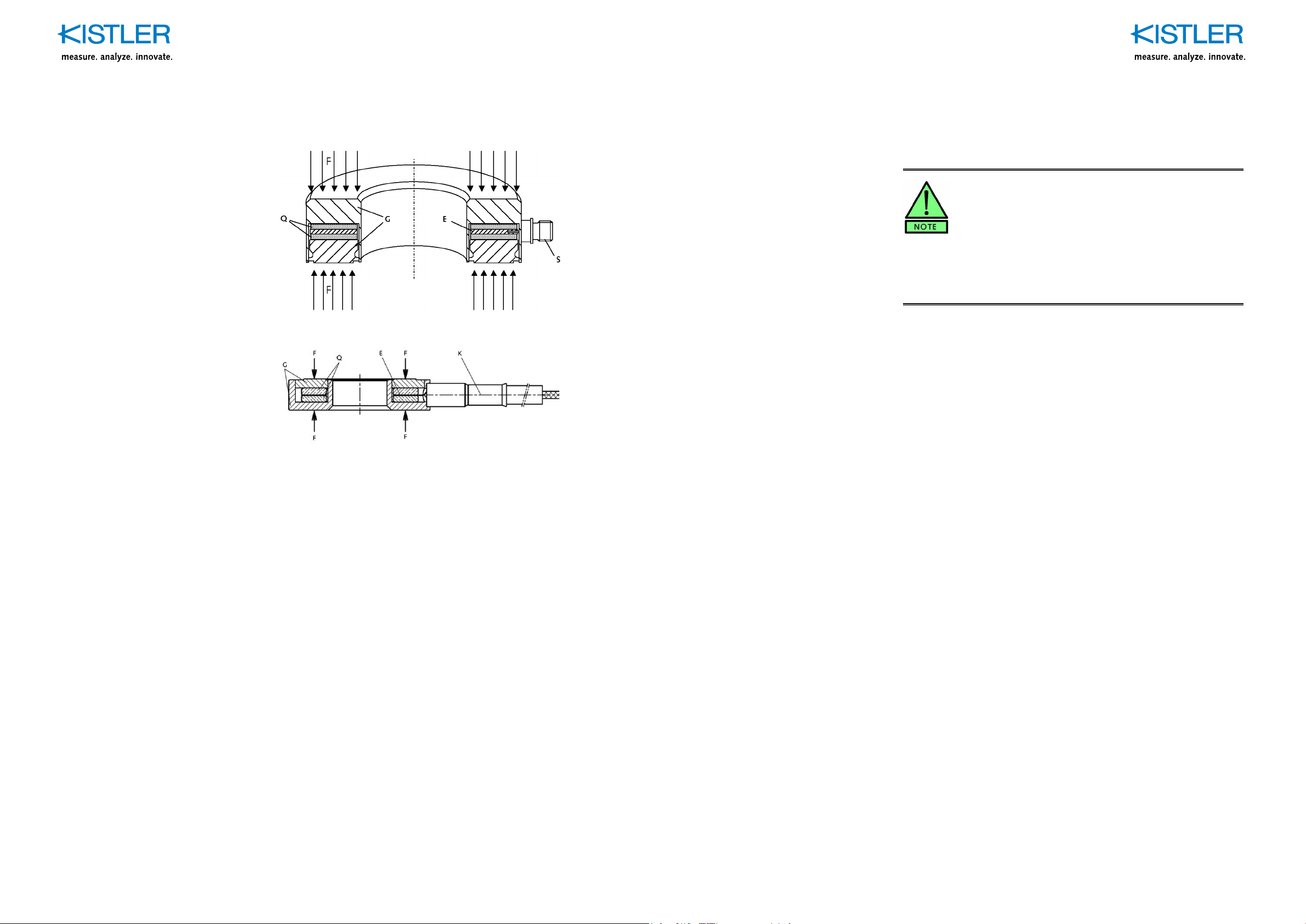

3.2 Sensor design and principle of operation ...........................................................................9

4. Mounting....................................................................................................................................11

4.1 General aspects of mounting ...........................................................................................11

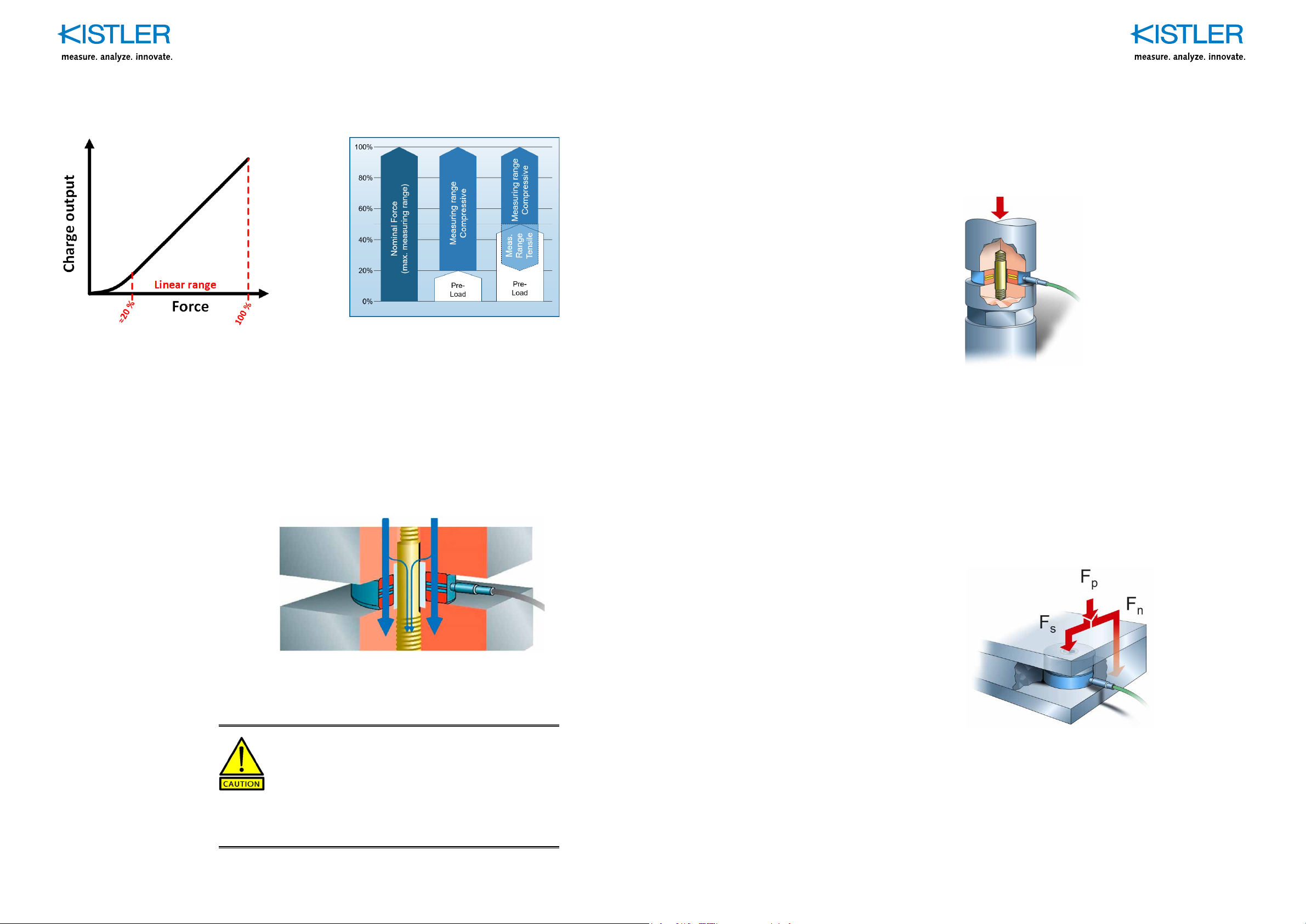

4.1.1 Pretension and preload .......................................................................................11

4.1.2 Sensor in direct path of force ..............................................................................13

4.1.3 Sensor in force shunt .........................................................................................13

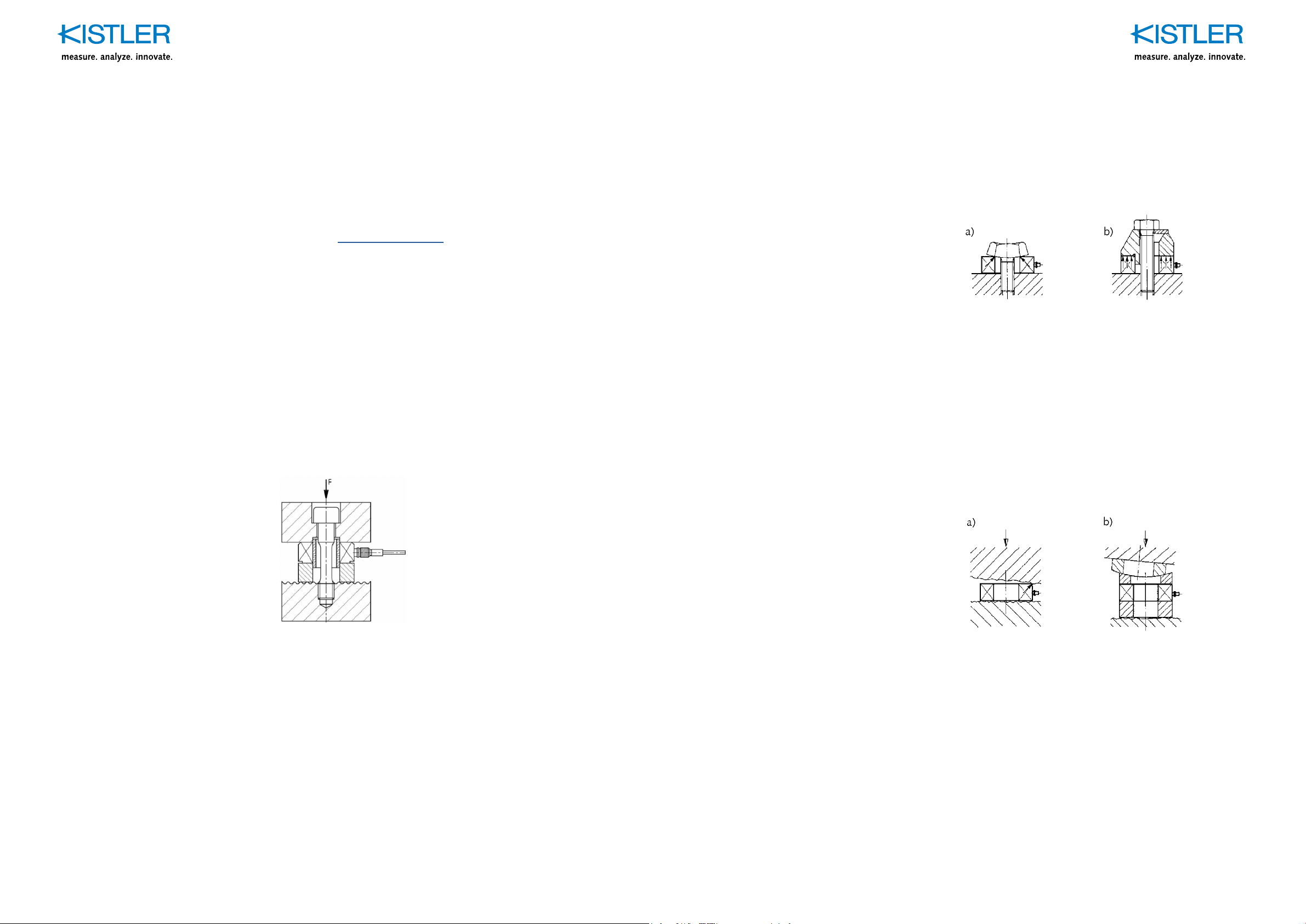

4.2 Structural design and force contact ..................................................................................14

4.2.1 Examples.............................................................................................................14

4.3 Effect of elasticity conditions on the measurements.........................................................17

4.3.1 Calculations related to engagement of force.......................................................18

4.3.2 Examples.............................................................................................................21

4.4 Mounting example ............................................................................................................24

4.5 Installation of sensor family 90x1C and 910xC ................................................................25

4.5.1 Type 9422A: mounting for compression forces only ...........................................25

4.5.2 Type 9420A: Mounting for both compression and tensile forces.........................27

4.6 Installation of big force sensors Type 9081C and 9091C .................................................29

4.7 Installation of a Slimline Sensor Types 9130C … 9137C .................................................30

4.7.1 Direct force path mounting ..................................................................................30

4.7.2 Type 9410A: mounting in force shunt mode........................................................31

5. Measurement.............................................................................................................................33

5.1 Basic arrangement of a measuring system ......................................................................33

5.2 Range selection and threshold .........................................................................................34

5.3 Measuring high-frequency phenomena ............................................................................35

5.4 Measuring quasistatic phenomena...................................................................................35

5.5 Instructions and safety precautions ..................................................................................36

Total pages 55

6. Calibration and maintenance...................................................................................................37

6.1 In-Situ calibration of force sensors ...................................................................................37

6.1.1 Working point calibration by peak value comparison ..........................................37

6.1.1.1 Test system requirements....................................................................38

6.1.1.2 Reference sensor installation ..............................................................38

6.1.1.3 Load application...................................................................................39

6.1.1.4 Calibration process worksheet.............................................................40

6.1.2 Kistler calibration service.....................................................................................43

7. Troubleshooting........................................................................................................................44

7.1 Diagnosisandrecticationoffaults ..................................................................................44

7.2 Repairing Load Washer ....................................................................................................45

8. Technical data ...........................................................................................................................46

8.1 Optional accessories ........................................................................................................46

9. Appendix....................................................................................................................................47

9.1 Glossary ...........................................................................................................................47

9.2 Measurement uncertainty .................................................................................................50

9.3 Linearity ............................................................................................................................51

9.4 Frequency range ..............................................................................................................53

9.5 Inuenceoftemperature...................................................................................................54