Wheel Pulse Transducer Type CWPTA

Page 2 CWPTA_002-612e-08.12_korrex

Content

1.

Introduction ................................................................................................................................... 3

2.

Important Notes .............................................................................................................................

2.1

For your Safety ..................................................................................................................... 4

2.2

D sposal Instruct ons for Electr cal and Electron c Equ pment ................................................ 5

2.3

Software Upgrades and Updates .......................................................................................... 5

3.

Product Overview .......................................................................................................................... 6

3.1

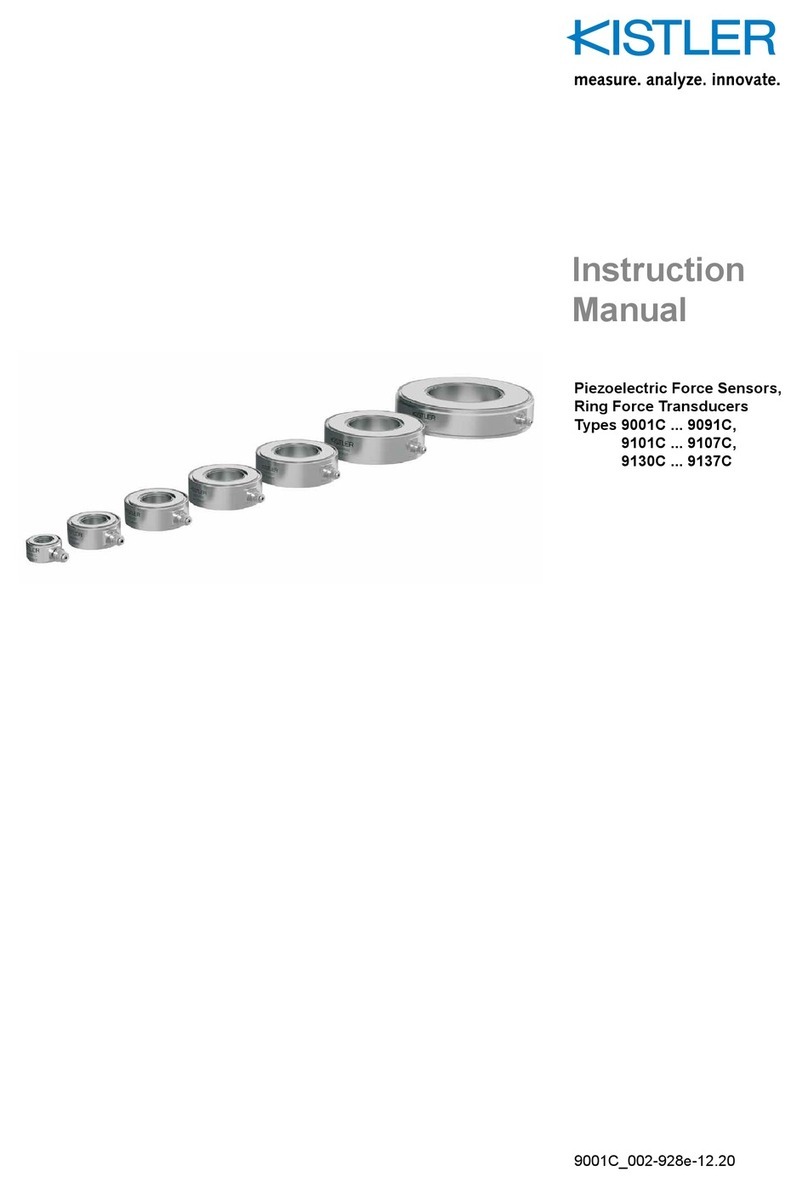

General Descr pt on .............................................................................................................. 6

3.2

Features ............................................................................................................................... 6

3.3

Appl cat on ........................................................................................................................... 7

3.4

Accessor es ........................................................................................................................... 7

.

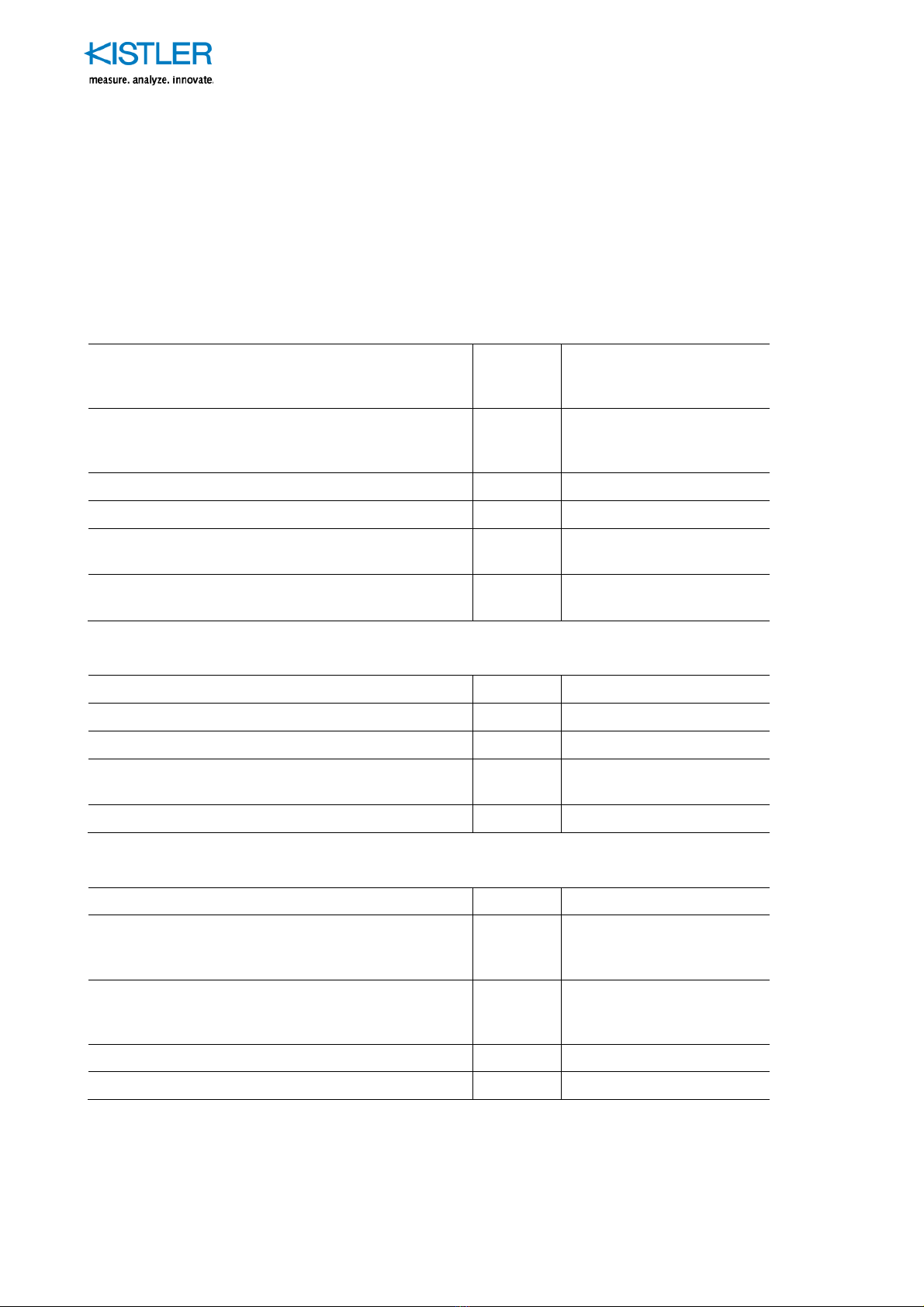

Technical Data ............................................................................................................................... 8

4.1

Spec f cat ons ........................................................................................................................ 8

4.2

P n Ass gnments ................................................................................................................... 9

4.2.1

12 p n M23 Flansch, male ....................................................................................... 9

4.2.1.1

Sensor Connector ..................................................................................... 9

4.2.1.2

Cable ..................................................................................................... 10

4.2.2

8 p n M12 Stecker ................................................................................................. 11

4.2.2.1

Sensor Connector ................................................................................... 11

4.2.2.2

Cable ..................................................................................................... 11

5.

Set-up and Connection ................................................................................................................ 12

5.1

Mount ng – General Notes ................................................................................................. 12

5.2

Sensor Mount ng J g ........................................................................................................... 13

5.3

Mont ng Instruct ons .......................................................................................................... 14

5.4

Connect ng the Sensor ....................................................................................................... 22

6.

Troubleshooting ........................................................................................................................... 23

6.1

Cables and Power Supply ................................................................................................... 23

6.2

S gnal Errors due to ncorrect Mount ng ............................................................................. 23

6.3

Serv ce ................................................................................................................................ 23

7.

Appendix ...................................................................................................................................... 2

Total pages: 24