OPERATION

DRAINING TANKS

32506 (11-98)

10

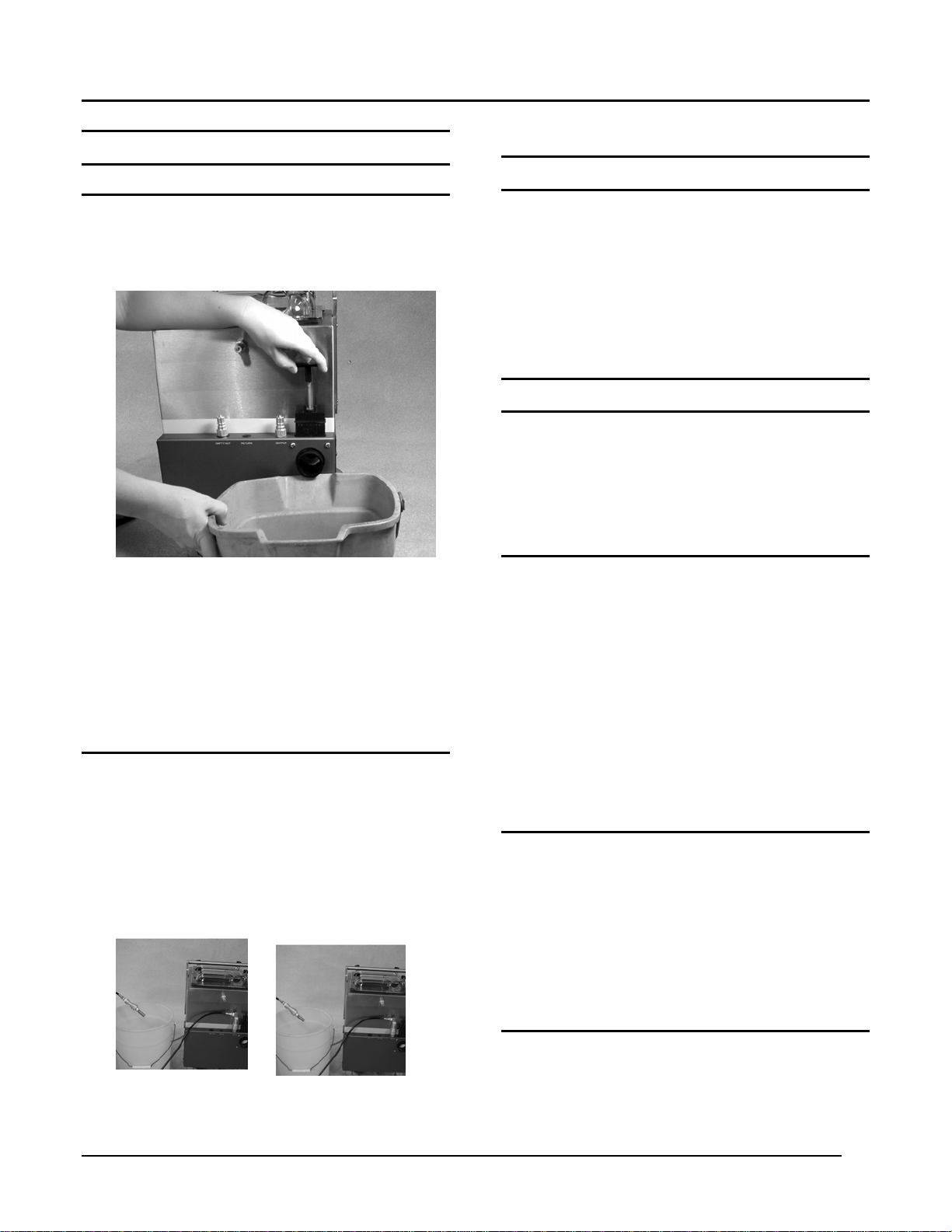

DRAINING RECOVERY TANK

1. Turn machine off.

2. Place a bucket under the drain valve and pull up

the handle (Figure 9).

3. Sediment in the bottom of the tank may be rinsed

out with the solution hose and empty-out nozzle

or with a garden hose. If particles fill the seals of

the valve, turn the vacuum on and slowly close

the valve a few times to vacuum them out. This

same procedure will remove any solution

remaining in the drain valve and prevent dripping.

DRAINING SOLUTION TANK

1. Turn on vacuum and remove water from solution

tank. If dry cleaning solution is remaining in

solution tank and it is to be saved, then perform

step 2 instead.

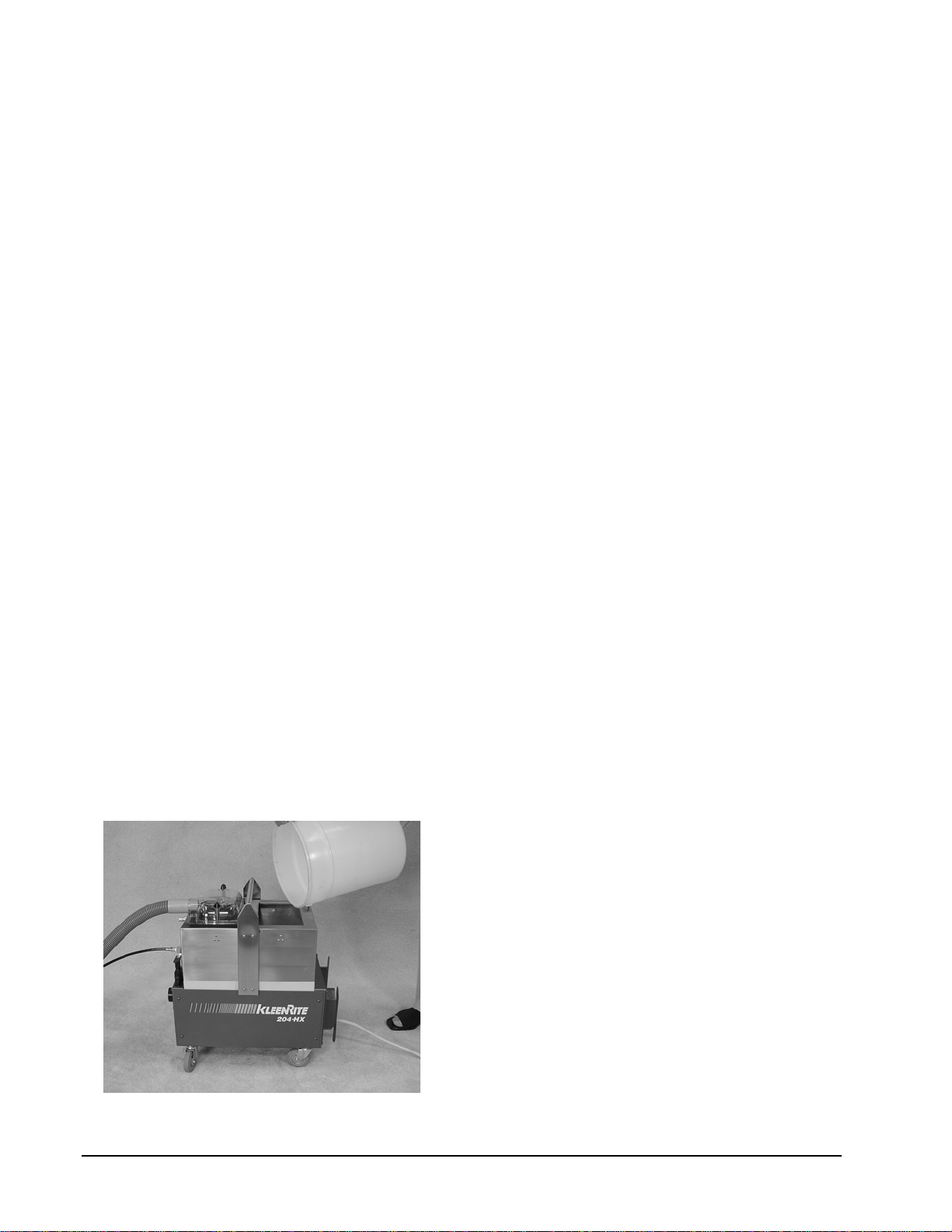

2. Remove empty-out nozzle from side of machine

FREEZE PROTECTION

and insert into end of solution hose and pump

into container (Figure 10).

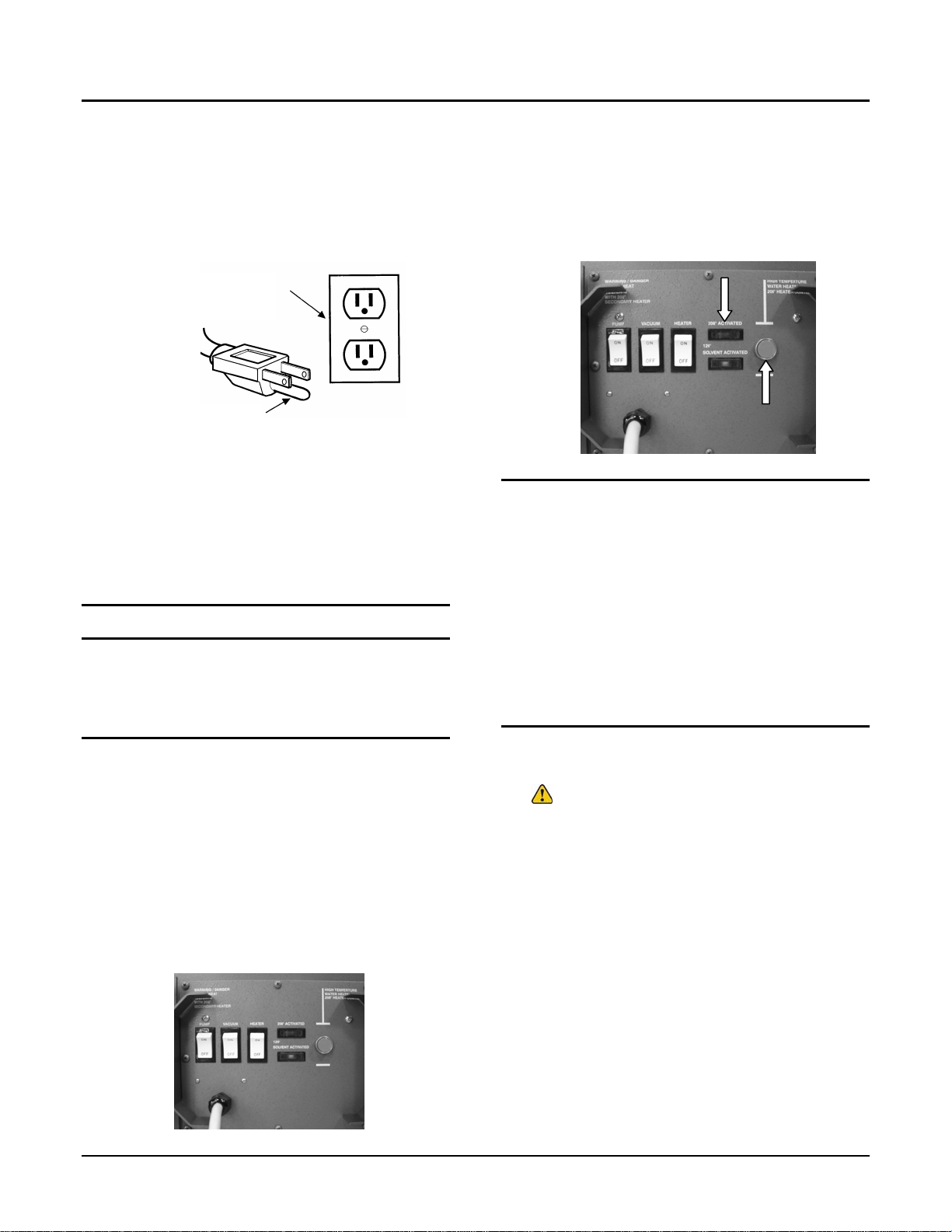

1. After draining solution tank as described in the

previous section (DRAINING SOLUTION TANK),

plug the far end of the solution hose into the

solution line purge connector located on the side

of the recovery tank (Figure 8).

2. Turn on vacuum and pump for 30 seconds. This

will fill the pump and hoses with air and prevent

freezing.

MACHINE MAINTENANCE

To keep machine in good working condition, simply

follow machine’s daily, weekly and monthly

maintenance procedures.

FOR SAFETY: When servicing machine, unplug

cord from wall outlet.

DAILY MAINTENANCE

(Every 4 Hours of Operation)

1. Empty and rinse out recovery tank thoroughly.

2. Clean vacuum filter screen.

3. When solution tank is empty, remove and clean

solution filter screen located in the bottom of the

solution tank.

4. Wipe off power cord and check for damage,

replace if necessary. Coil cord neatly after use.

5. Clean machine with an all purpose cleaner and

damp cloth.

WEEKLY MAINTENANCE

(Every 20 Hours of Operation)

1. Inspect vacuum hoses for holes and loose cuffs.

2. Inspect spray pattern for plugging. If plugged,

remove spray tips and soak them in acetic acid

solution for up to six hours. Do not use pointed

objects to unplug tips, damage will occur.

3. Lubricate female hose couplers with lightweight

oil.

MONTHLY MAINTENANCE

(Every 80 Hours of Operation)

1. Inspect vacuum and pump motors for excessive

arcing. If arcing is present replace them.

FOR SAFETY:

Fig. 9

Fig. 10