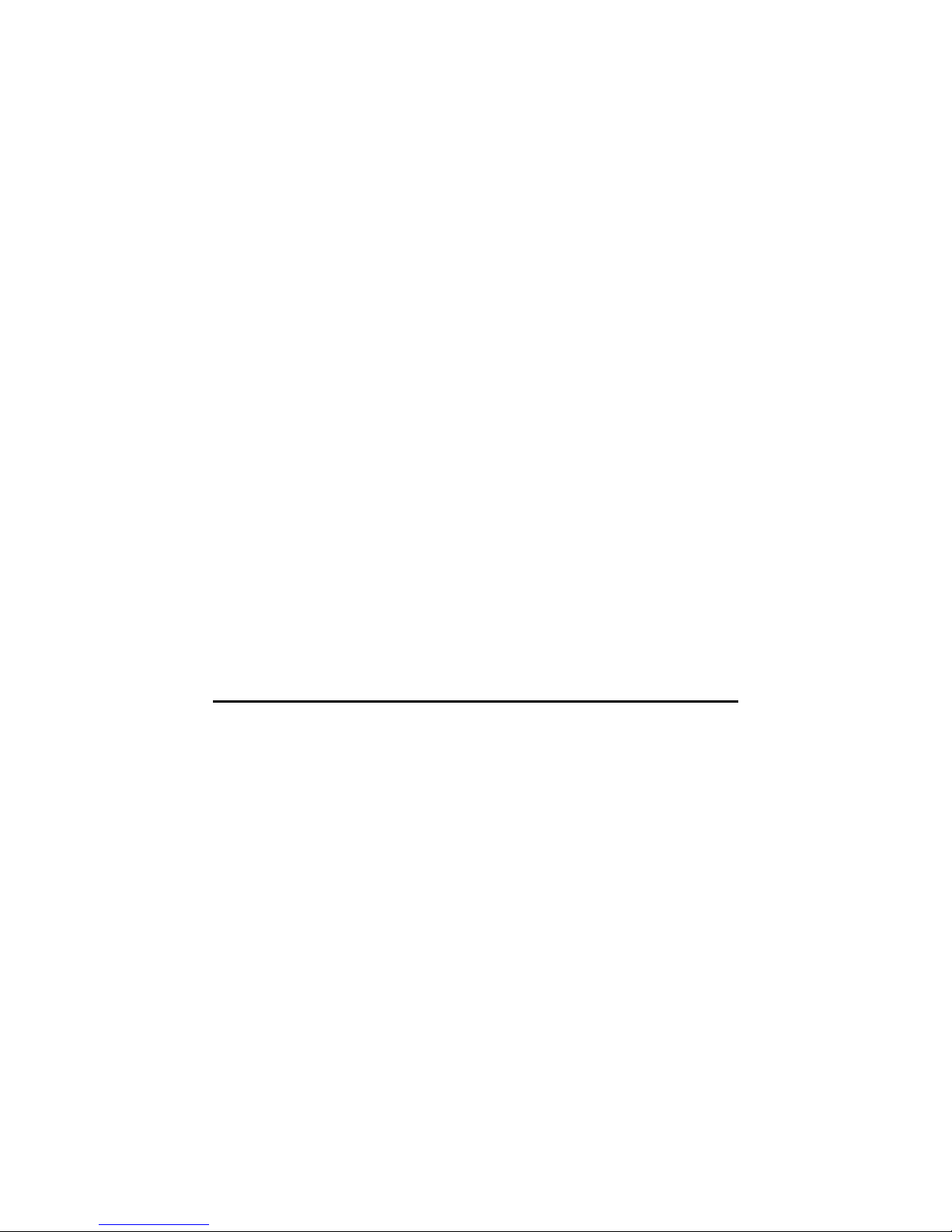

5. NOTE: For Remote Inlet A r F lter Installat on, use the prov ded plast c a r l ne and

f tt ng, as well as the prov ded a r f lter cl p.

6. Th s a r compressor comes w th a heavy duty heat res stant sta nless steel bra ded

leader hose w th ¼” f tt ngs. Th s leader hose s des gned to prolong the l fe of your

a r l ne. Do not remove th s leader hose from a r compressor.

7. IMPORTANT: The leader hose that comes w th your compressor has a bu lt- n nl ne

check valve. Do not remove nl ne check valve from leader hose.

8. Select a proper locat on to mount leader hose w th hose bracket prov ded. Avo d

locat ons where leader hose may become tangled w th w res and other hoses.

9. Connect compressor’s pos t ve lead w re to one of the leads of your pressure sw tch,

or, f you are us ng the Kle nn 6850 nstallat on k t, connect the compressor’s pos t ve

lead to p n 30 of the relay.

10. Make sure that your compressor setup s properly fused. The compressor pulls

approx mately 10 amps of power.

11. Always locate fuse as close as poss ble to power source.

12. Before connect ng to power source, check to make sure that all connect ons are made

properly.

13. Connect and test compressor system by runn ng the compressor for a short t me to

bu ld up pressure n your a r tank.

14. Once a r pressure reaches the preset cut out pressure of your pressure sw tch, the

compressor w ll shut off. Inspect all a r l ne connect ons for leaks w th soap and

water solut on. If a leak s detected, the a r l ne may not be cut squarely or pushed all

the way n. T ghten connect ons f needed.

15. Always use a “sw tched” power source that only suppl es power to your compressor

when the veh cle s runn ng.

COMPRESSOR OPERATING INSTRUCTIONS

IMPORTANT: The compressor has a max mum work ng pressure of 120 PSI and s

capable of 9% duty cycle. It s des gned for use w th a r horns, a r bags and other

accessor es that ut l ze the compressed a r stored n the tank. It s not des gned for

cont nuous use appl cat ons such as t re nflat on or a r tools. Always operate the

compressor at or below the MAXIMUM PRESSURE RATING of the compressor.

Operat on exceed ng max mum pressure rat ngs and or duty cycle w ll result n damage

to a r compressor.

1. Should your a r compressor unexpectedly shut off wh le n use; do not attempt to

restart the a r compressor. Turn off your gn t on, or f th s s not poss ble, d sconnect

the power to the compressor. After allow ng a r compressor to cool off for about 30

m nutes, you can safely resume use of the a r compressor by turn ng on the a r

compressor.

2. To prevent d scharge of your veh cle’s battery and to prov de peak performance, we

strongly recommend that you keep the veh cle’s eng ne runn ng wh le us ng the a r

compressor.

3. ONLY OPERATE THE AIR COMPRESSOR IN WELL-VENTILATED AREAS.