TABLE OF CONTENTS

1.0 SAFETY..................................................................................................................3

1.1 INSPECTION....................................................................................................4

1.2 LIMITATIONS....................................................................................................4

2.0 GENERAL..............................................................................................................4

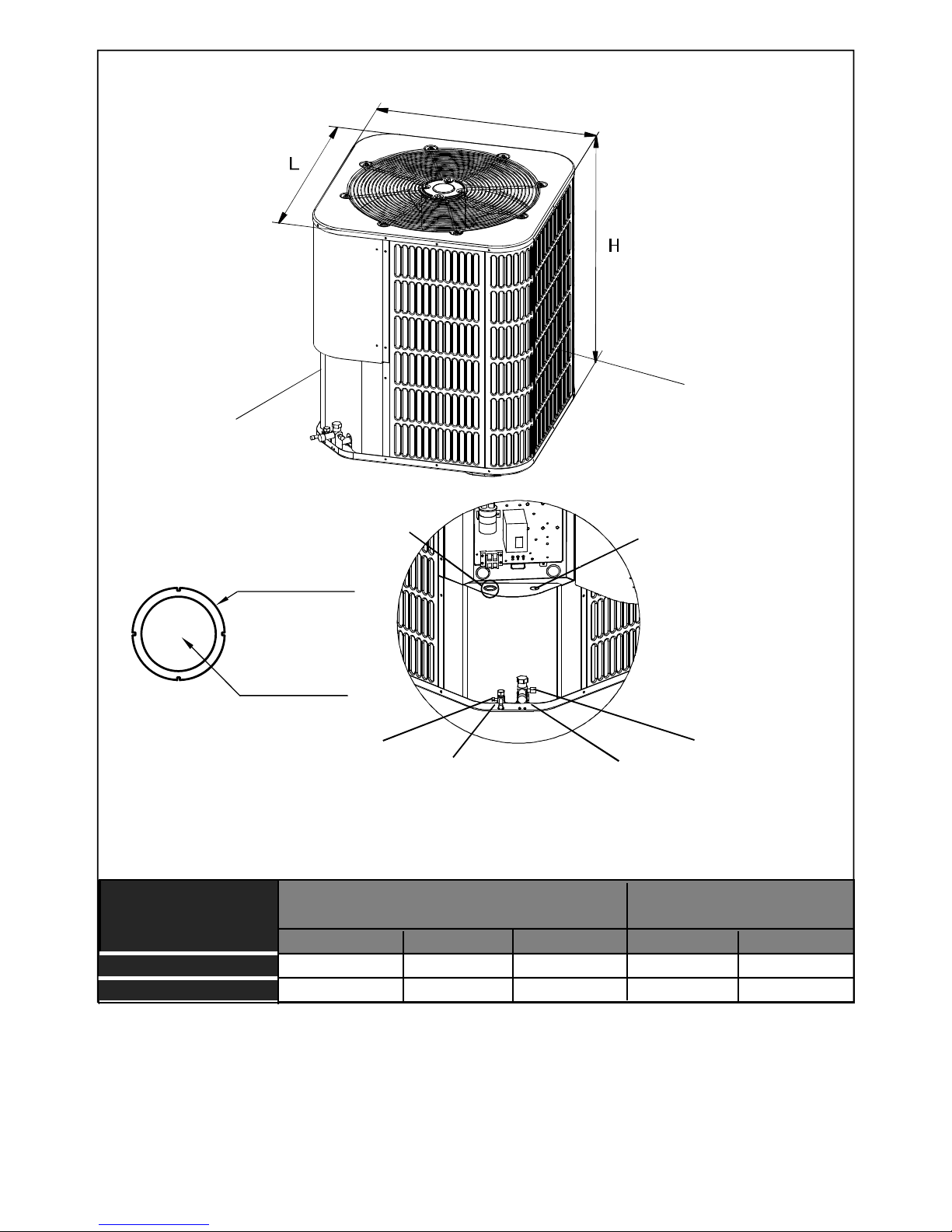

3.0 UNIT INSTALLATION............................................................................................6

3.1 LOCATION.......................................................................................................6

3.2 GROUND INSTALLATION...............................................................................6

3.3 ROOF INSTALLATION.....................................................................................6

3.4 UNIT PLACEMENT..........................................................................................6

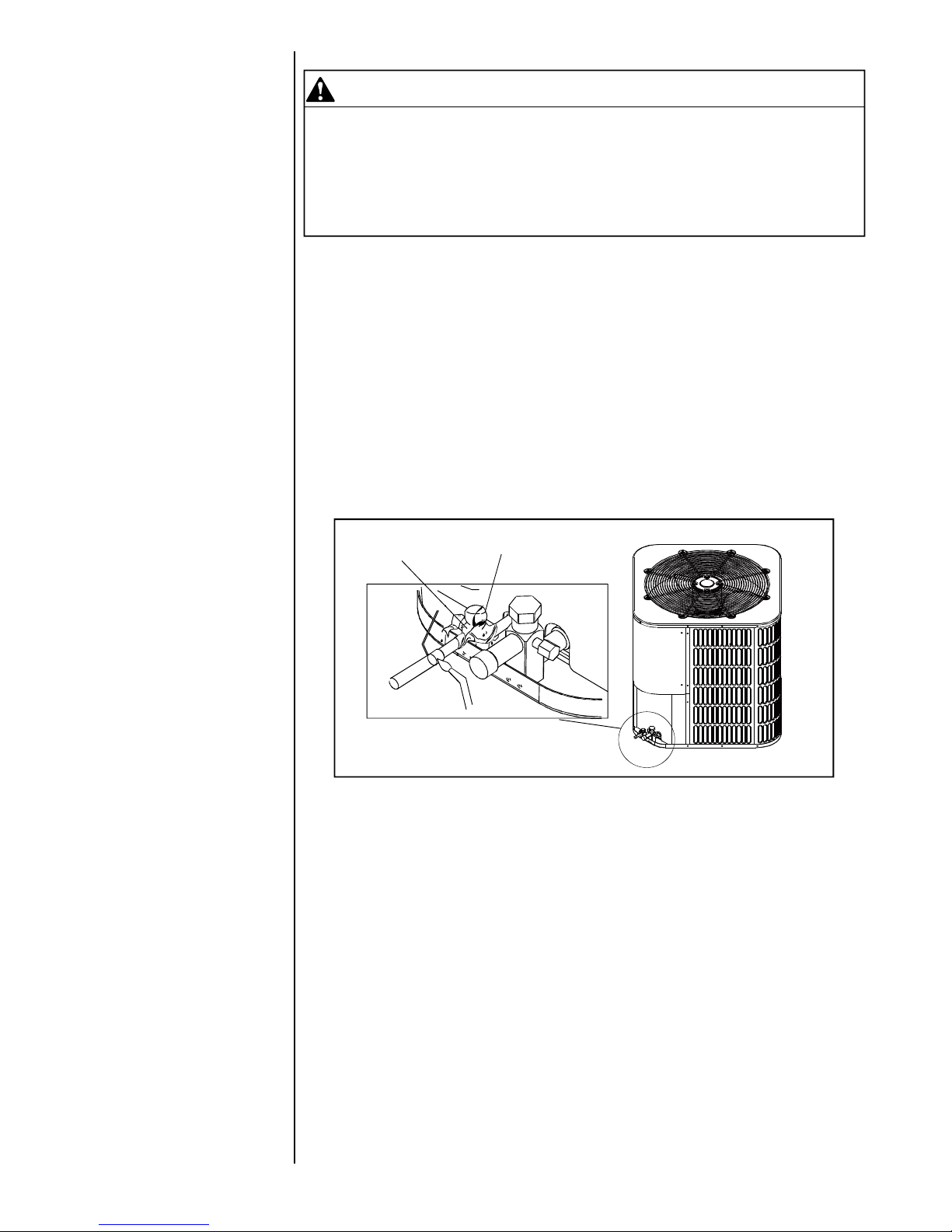

3.5 PRECAUTIONS DURING LINE INSTALLATION.............................................7

3.6 PRECAUTIONS DURING BRAZING OF LINES..............................................8

3.7 PRECAUTIONS DURING BRAZING SERVICE VALVE..................................9

3.8 UNIT MOUNTING...........................................................................................10

3.9 FACTORY-PREFERRED TIE-DOWN METHOD............................................11

3.10 REMOVING THE TOP PANEL AND MOTOR..............................................12

4.0 ELECTRICAL CONNECTIONS...........................................................................13

4.1 GENERAL INFORMATION & GROUNDING .................................................13

4.2 FIELD CONNECTIONS POWER WIRING ....................................................13

5.0 EVACUATION......................................................................................................14

6.0 INTERCONNECTING TUBING............................................................................14

6.1 VAPOR AND LIQUID LINES .........................................................................14

6.2 MAXIMUM LENGTH OF LINES ....................................................................14

6.3 VERTICAL SEPARATION .............................................................................14

7.0 SYSTEM OPERATION........................................................................................14

7.1 COMPRESSOR CRANKCASE HEATER (CCH)...........................................14

7.2 LINE SIZING..................................................................................................15

7.3 PROTECTION FUNCTION INTRODUCTION...............................................16

7.4 DEFROST MODE..........................................................................................16

7.5 MANUA DEFROST MODE.............................................................................17

8.0 CHECKING REFRIGERANT CHARGE .............................................................17

8.1 CHARGING BY LIQUID PRESSURE............................................................17

8.2 CHARGING BY WEIGHT ..............................................................................18

8.3 FINAL LEAK TESTING ..................................................................................18

9.0 OWNER INSTRUCTINGS....................................................................................18

10.0 WIRING DIAGRAM............................................................................................19

2