847-336-7556

www.unitedsci.com

3

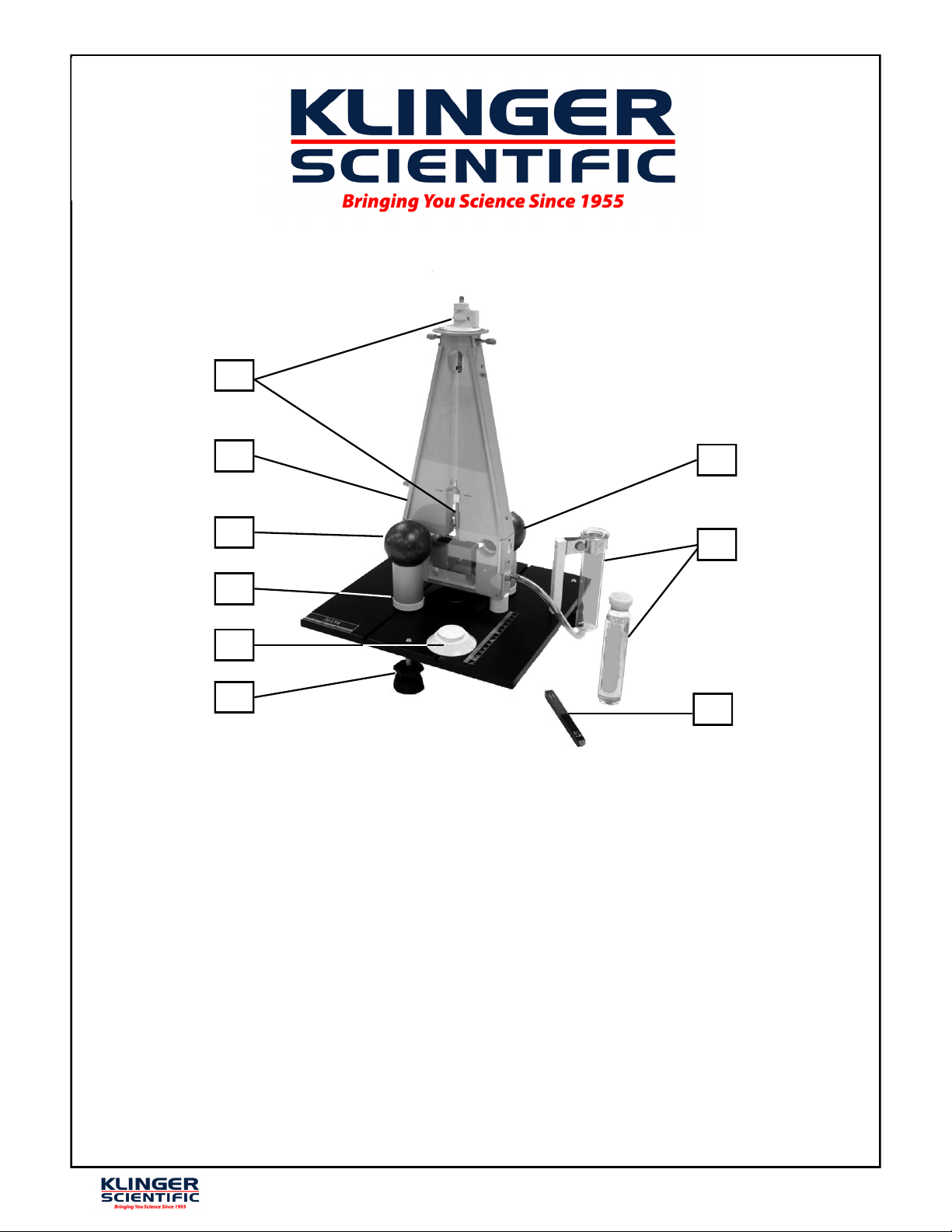

The torsion balance is housed in a solid aluminum main body (18) with glass win-

dows (9) on both sides to eliminate drafts.

The adjusting nut (3) on the top can be used to raise or lower the upper suspension rod

(7) in order to adjust the vertical position of the balance. The angle adjustment block

(2), angle indicator disk (4) and the circular scale (5) are used to read the angle the

balance is rotated from its equilibrium position. The locking screws (6) on the upper

side of the body can fix the upper suspension rod in its angular equilibrium position.

The filament (8), 150mm long and made of beryllium bronze, has connector plates (10)

at each end and connects the upper and lower suspension rods (7,34). A concave mirror

(12) with 2m focal length is mounted on the lower suspension rod. Under the mirror

are the locking rod, a pair of lead balls of 10.0mm diameter (15) and the damping vane

(17), which projects into in a damping trough (16).

The locking screw (13) on the side can raise or lower the locking mechanism

(14).With the locking mechanism lowered, the balance is suspended on the filament

and can rotate freely. When the mechanism is raised, it lifts the balance by the locking

rod (33) and presses the arm of the balance against the body, removing the load from

the filament and immobilizing the balance.

The filament is extremely delicate and the load of the balance stresses it highly. The

balance should only be released and allowed to swing freely when an experiment is in

progress. At all other times, the balance should be locked to preserve the filament.

The main body is mounted on an aluminum base (21). The three leveling screws (22)

under the base are used to level the device. The two grooves on the base serve as

guides for the sliding ball supports (24). The ball support cylinders (25) for the large

lead balls (26) rest on the sliding blocks. The distance between the large balls can be

measured by the scales (20) along the grooves.

The oil damping system is mounted on one side of the base and connected to the

damping chamber (16) through a tube (27).

Mass of large lead balls: Approximately 1.5kg

Difference between the two balls < 0.002kg

Mass of small lead balls: Approximately 0.02kg

Difference between the two balls <0.0005kg

Arm length of the torsion balance: 5.0x10-2m

Torsion Filament: Length: approximately 150mm

Cross sectional area: 0.145±0.08mm2

Material: Be-Sn-Cu alloy

Period of the torsion balance 590±10sec.

Scale: 140mm with 1mm divisions

Full-scale error < 0.1mm.

Damping method: Silicone oil

Relative error of Gravitational Constant: < 15%

Operating temperature: 10 –40°C

Relative humidity: < 40%

Operating location: Should be free from vibration, sunlight,

radiant heat, magnetic and electric fields

Dimensions: 300x300x420mm

Net weight: 12kg

www.KlingerScientic.com