This warranty does not cover cosmetic damage or damage due to acts of God, accident, misuse,

abuse, negligence, commercial use, or modification of or to any part of the Product. This warranty

does not cover damage due to improper installation, operation, or maintenance. This warranty is

limited to the original purchaser and is not transferable. In no case shall our company’s liability

exceed the original cost of the purchased product and will not cover consequential, incidental or

collateral damage. Our company reserves the right to inspect any and all equipment involved in a

warranty claim. Repair or replacement decisions are at the sole discretion of our company. Further,

our company reserves the right to change or modify this warranty without notice.

REPAIR OR REPLACEMENT AS PROVIDED UNDER THIS WARRANTY IS THE EXCLUSIVE

REMEDY OF THE CONSUMER.

As our company has no control over use, setup, final assembly, modification or misuse, no liability

shall be assumed nor accepted for any resulting damage or injury. By the act of use, setup or

assembly, the user accepts all resulting liability.

If you as the purchaser or user are not prepared to accept the liability associated with the

use of this product, you are advised to return this product immediately in new and unused

condition to he place of purchase.

Contents of Kit

2 19

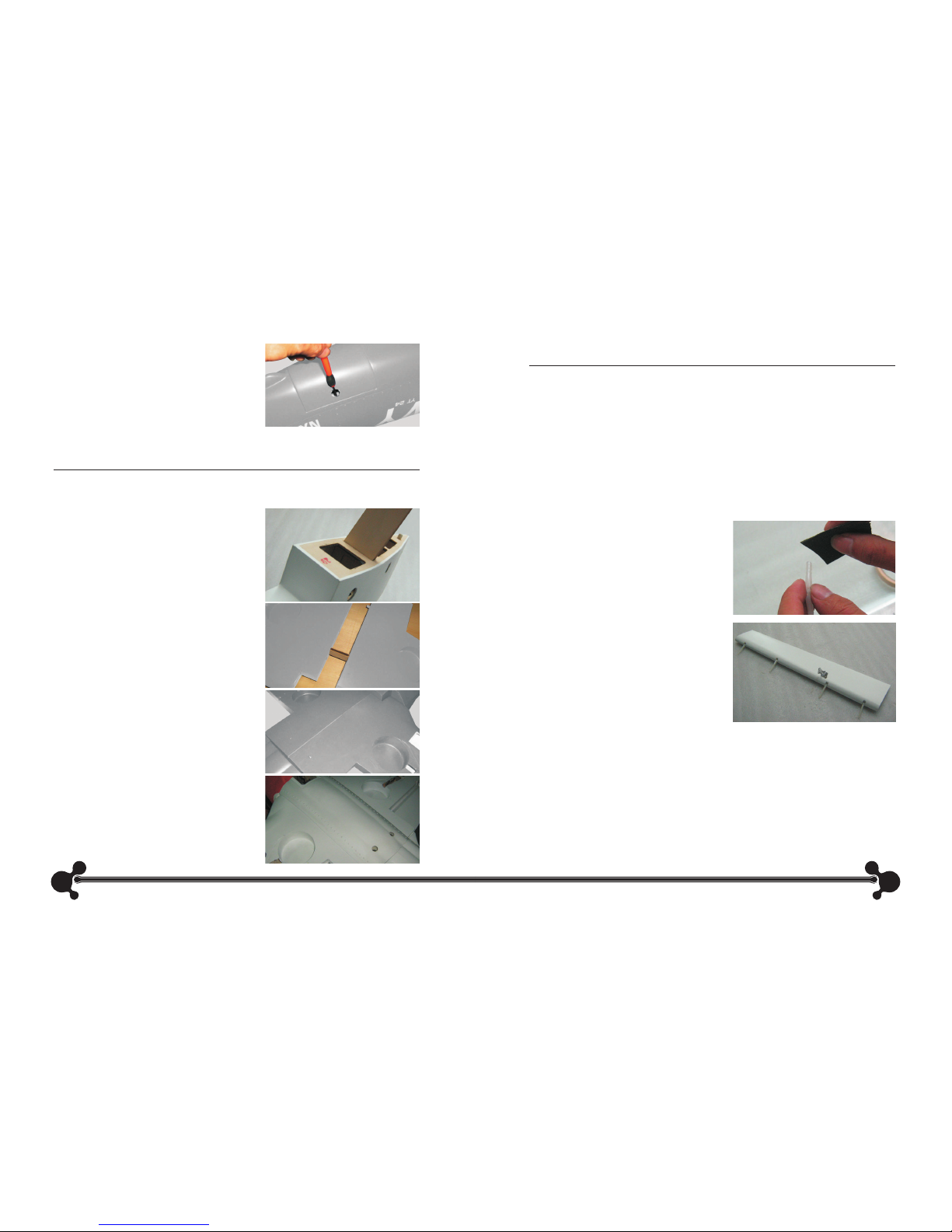

As a large model, the airplane is critical of proper battery use, control linkage setups and flying

techniques. Please pay particular attention to the following areas.

Preflight

Maintain the proper mechanical advantage on all control surface linkages.

Check the radio installation and make sure all the control surfaces are moving correctly (i.e. the

correct direction and with the recommended throws). Test run the engine and make sure it

transitions smoothly from idle to full throttle and back. Also ensure the engine is tuned according to

the manufacturer’s instructions, and it will run consistently and constantly at full throttle when

adjusted. Check all the control horns, servo horns, and clevises to make sure they are secure and in

good condition. Replace any items that would be considered questionable. Failure of any of these

components in flight would mean the loss of your airplane.

Never attempt to make full throttle dives!

Large models perform much more like full-size airplane than small models. If the airframe goes too

fast, such as in a high throttle dive, it may fail. The model should be flown like a full-scale airplane.

Throttle management is absolutely necessary.

Hardware checks

Double-check the setscrews in all control horns to be sure they are very tight. Periodically check

these to be sure they have not loosened over time. Always use threadlock on metal-to-metal

fasteners.

Receiver Battery Selection

Be sure adequate batteries are used to power the receiver. It is recommended that two identical

6-volt receiver packs are used. Each pack must have a minimum of 2700mAh capacity. Use packs of

3000mAh when super high torque servos are used.

Range check

Always range check the radio system per the manufacturer's instructions before the initial test flight

and periodically afterward.

Check the voltage of the on-board packs

ALWAYS use an ESV with a 1-amp load to check the receiver battery packs and the ignition pack

before each and every flight. If there is any doubt that the packs are questionable, DO NOT FLY until

the packs are recharged.

Front Landing Gear Cover for T-28 Trojan