KMS Fuel/FA23 manual

Version 3.01 2

Contents page.

1KMS (Kronenburg Management Systems)............................................................... 3

2Software installation....................................................................................... 4

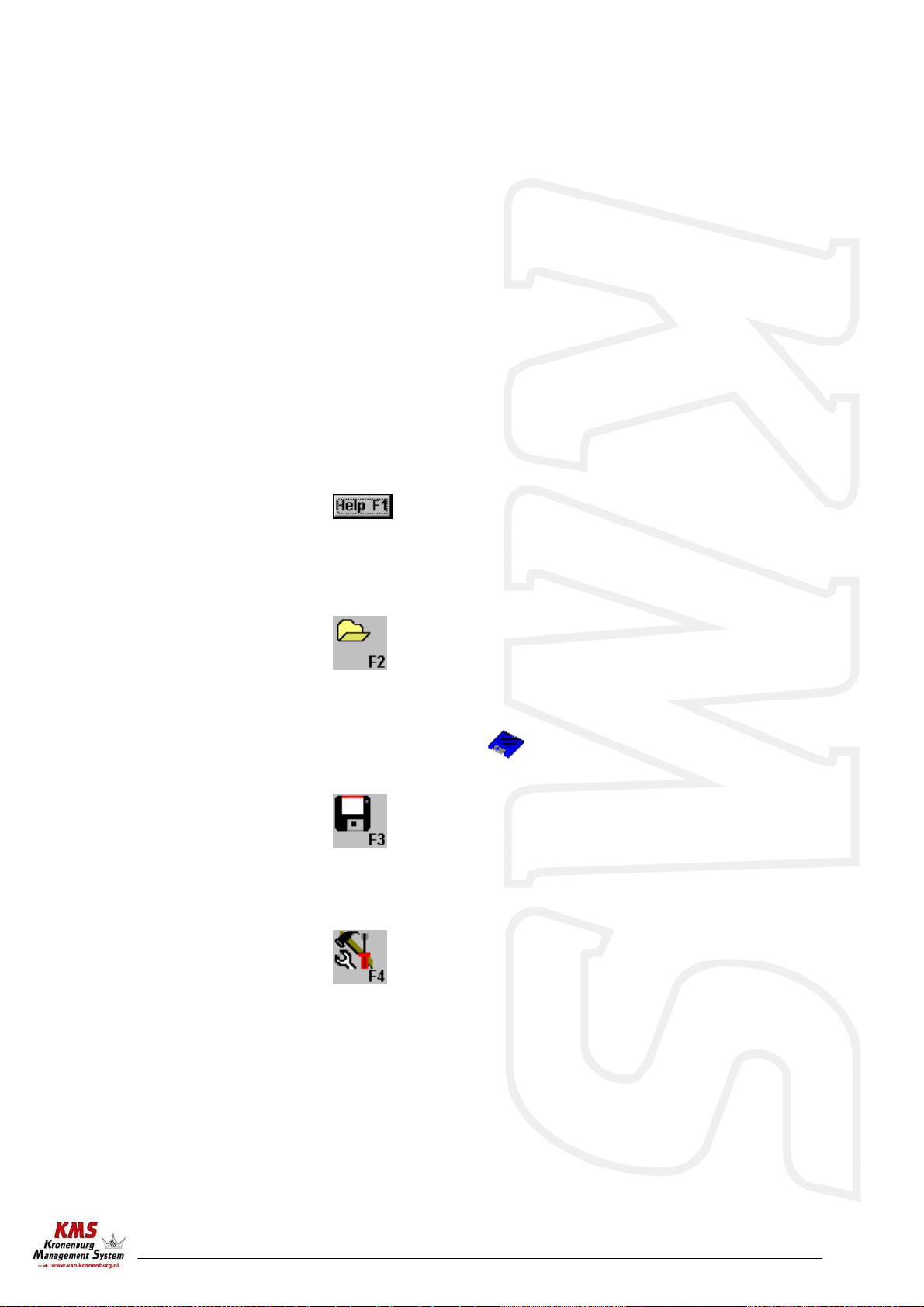

3KMS software................................................................................................. 5

3.1 The injection characteristic diagram ............................................................. 5

3.2 The function bar....................................................................................... 6

3.2.1 Function key F1 ..................................................................................... 6

3.2.2 Function key F2 ..................................................................................... 6

3.2.3 Function key F3 ..................................................................................... 6

3.2.4 Function key F4 ..................................................................................... 6

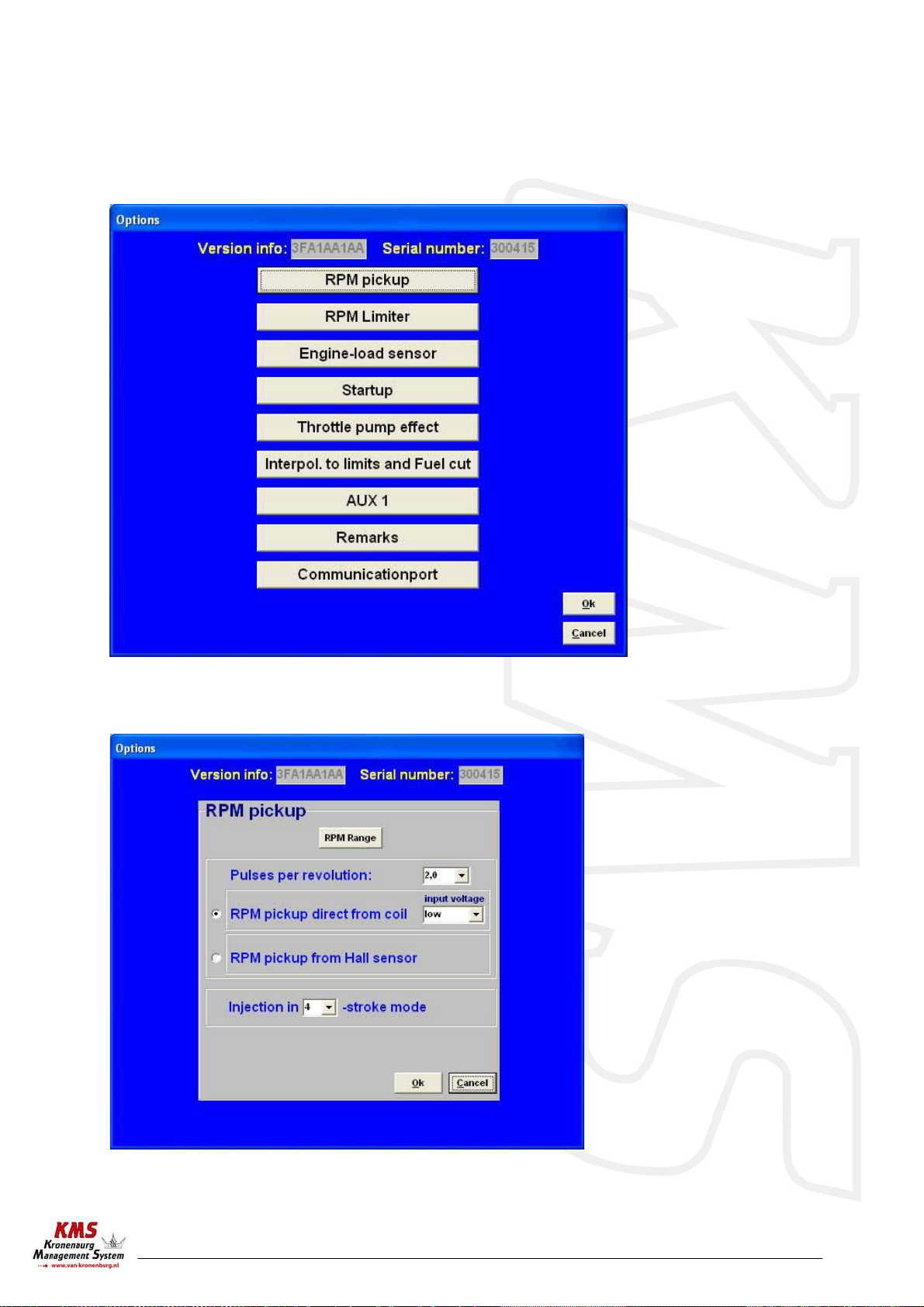

3.2.4.1 Options......................................................................................... 7

3.2.4.1.1 RPM pickup................................................................................ 7

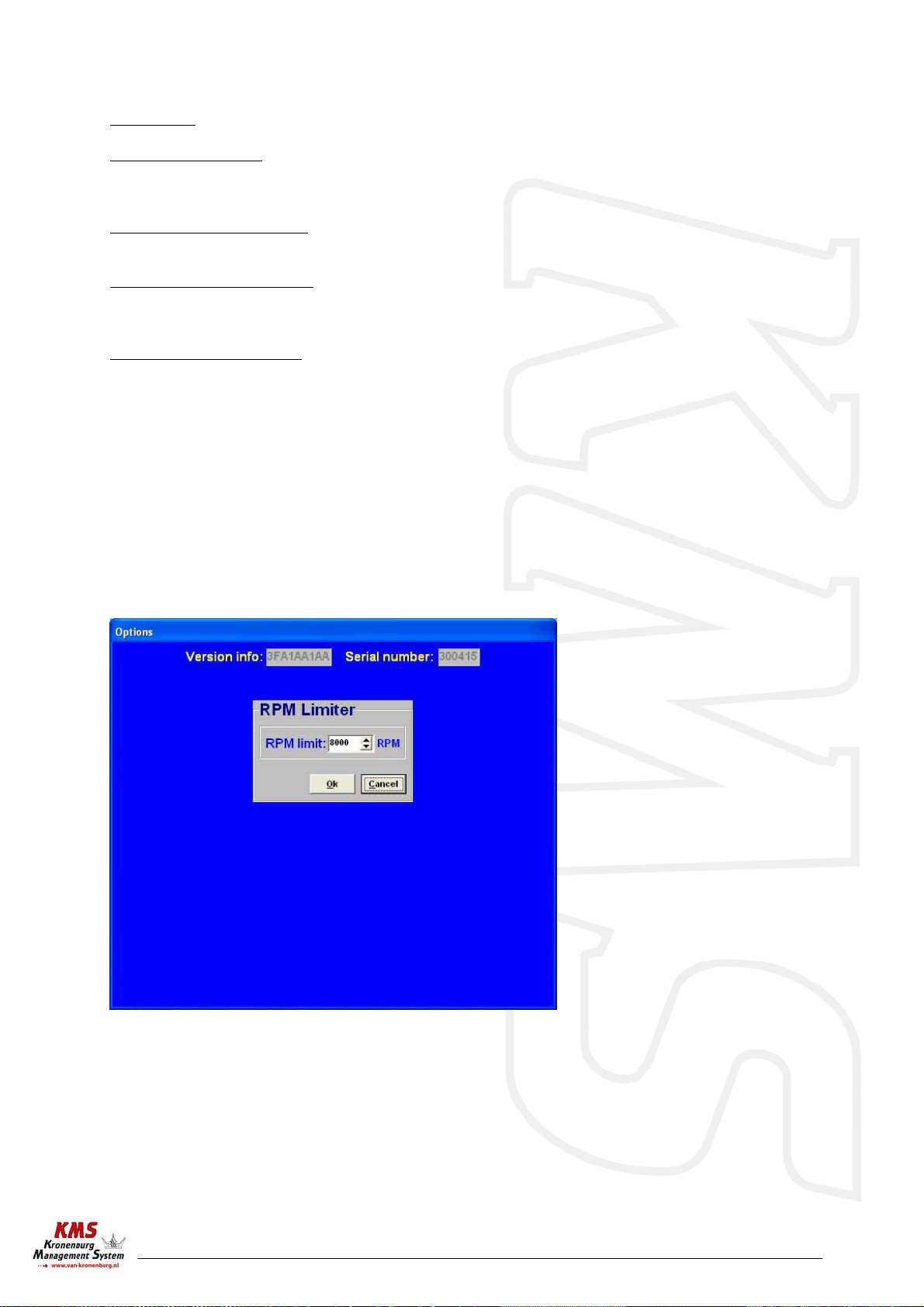

3.2.4.1.2 RPM limiter (not available at older Fuel systems).................................. 8

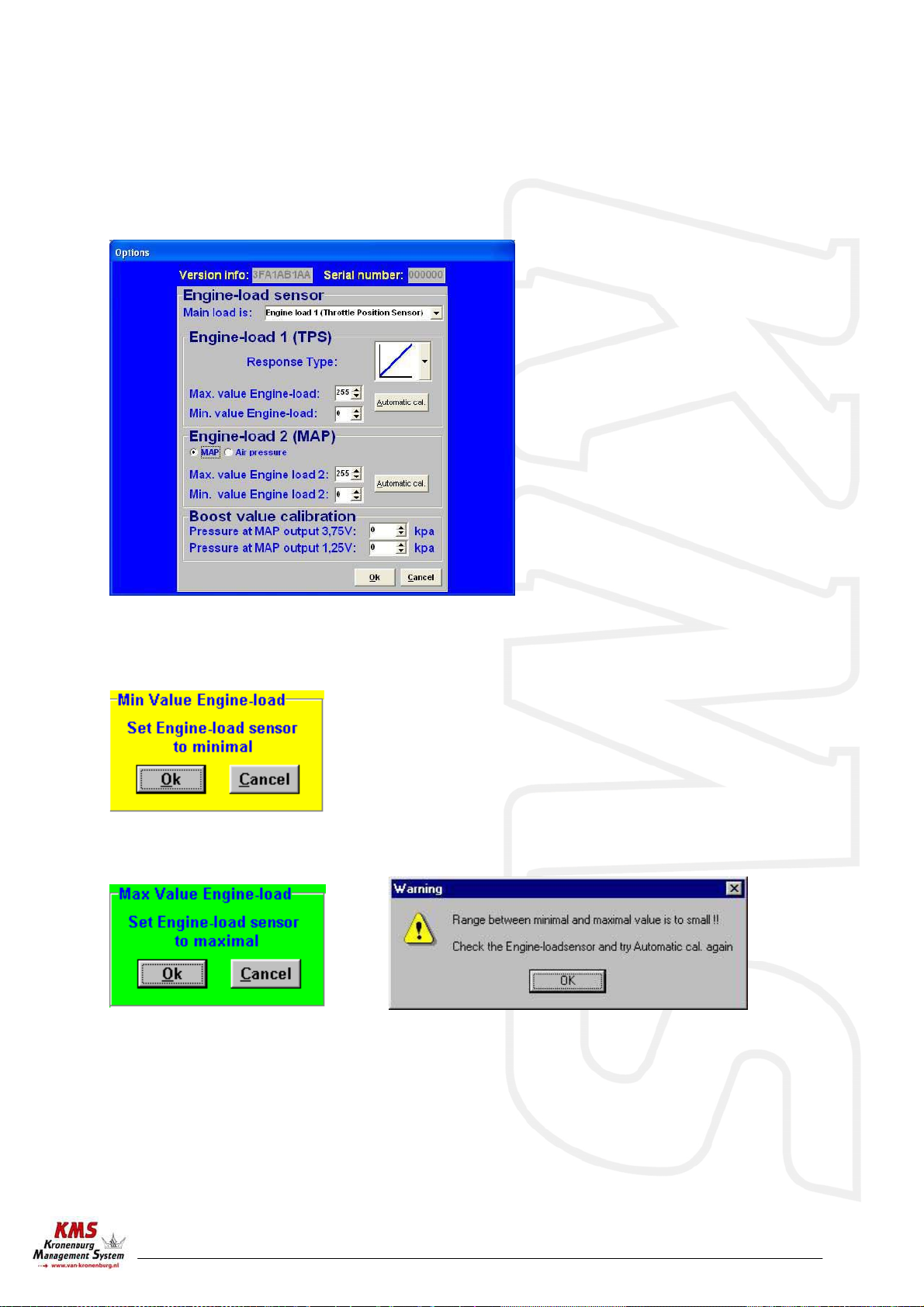

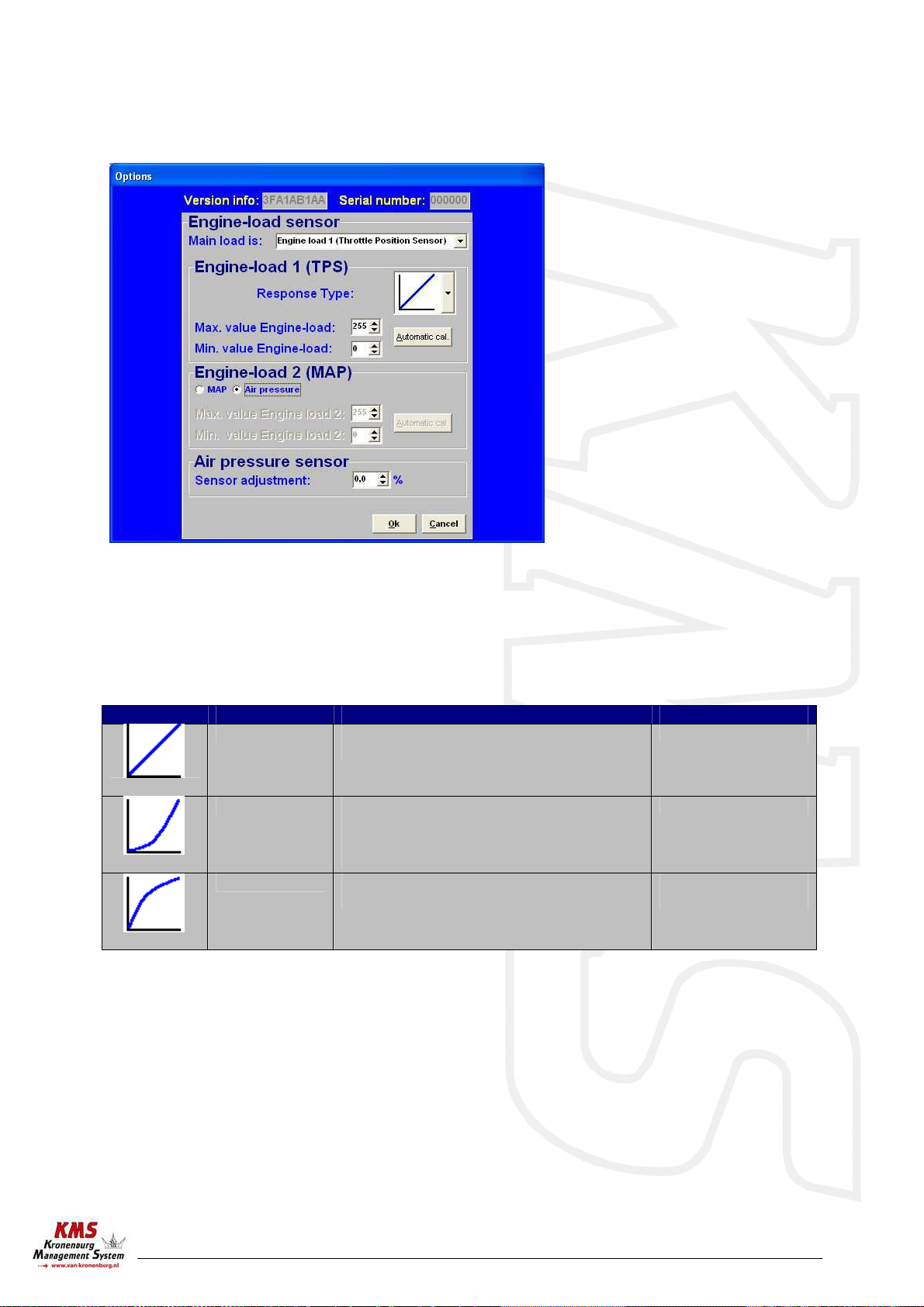

3.2.4.1.3 Engine load sensor....................................................................... 9

3.2.4.1.4 Start-up...................................................................................11

3.2.4.1.5 Throttle pump effect...................................................................12

3.2.4.1.6 Interpolations to limit and fuel cut..................................................12

3.2.4.1.7 AUX 1 (Second stage on older Fuel system) ........................................13

3.2.4.1.8 Correction-table (only for older Fuel systems) ....................................14

3.2.4.1.9 Remarks .................................................................................14

3.2.4.1.10 Communication port .................................................................15

3.2.5 Function key F5 ....................................................................................15

3.2.6 Function key F7 ....................................................................................17

3.2.7 Function key F10...................................................................................18

3.3 The communication bar............................................................................ 19

4Programming ............................................................................................... 21

4.1 Manual changing..................................................................................... 21

4.2 Bar charts ............................................................................................. 21

5Hardware installation.................................................................................... 22

5.1 Fitting the ECU....................................................................................... 22

5.2 Connecting the communication cable........................................................... 22

6Fault tracing................................................................................................ 23

7Specifications .............................................................................................. 24

8Wiring diagram FA23 ..................................................................................... 25

9Wiring examples KMS FA23.............................................................................. 26

10 Wiring example (older) KMS Fuel ...................................................................... 29