KMS IB/IA23 manual

Version 3.01 2

Contents

1KMS (Kronenburg Management System) .............................................3

2Software installation ....................................................................4

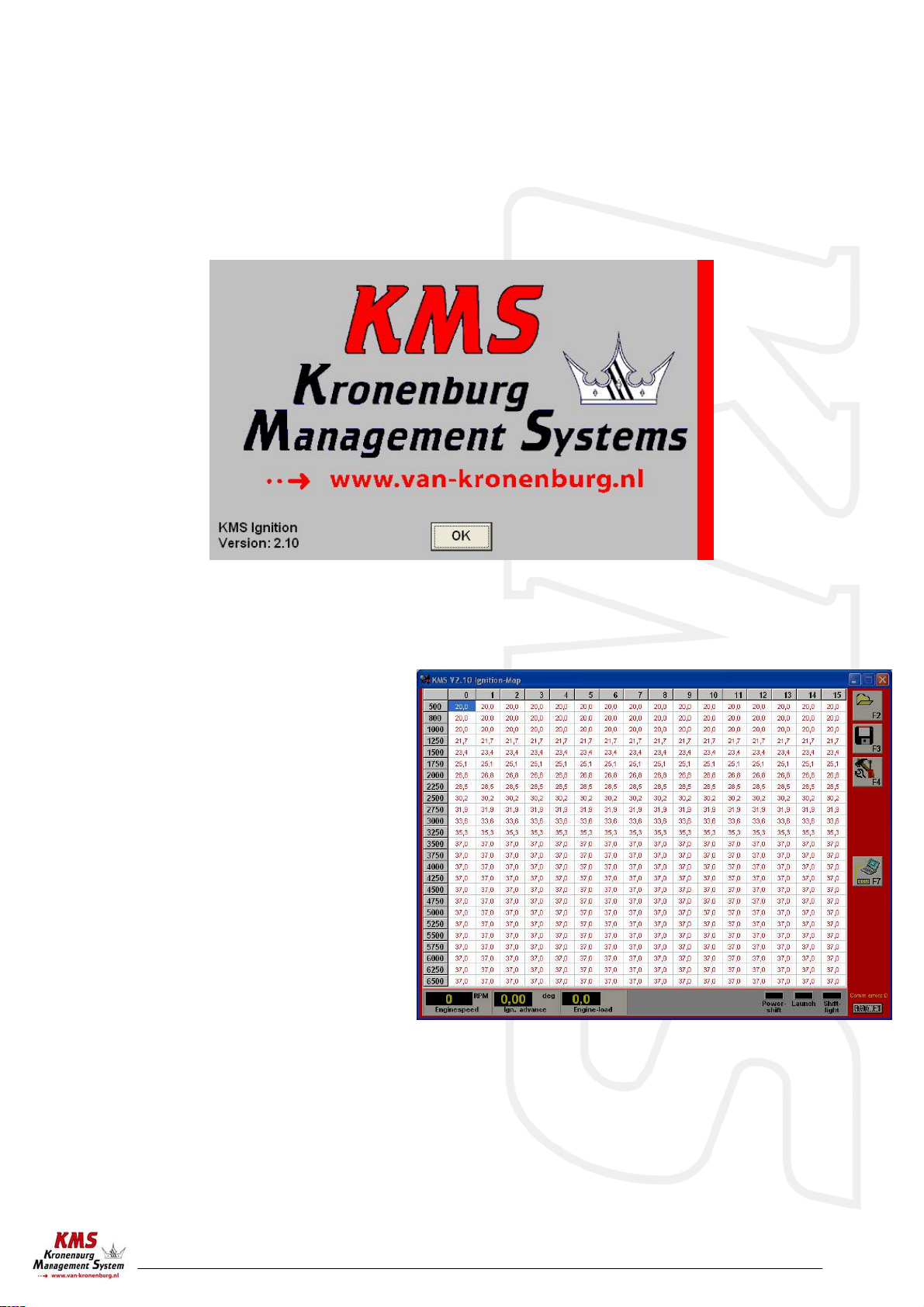

3KMS software ..............................................................................5

3.1 The ignition characteristic diagram .............................................5

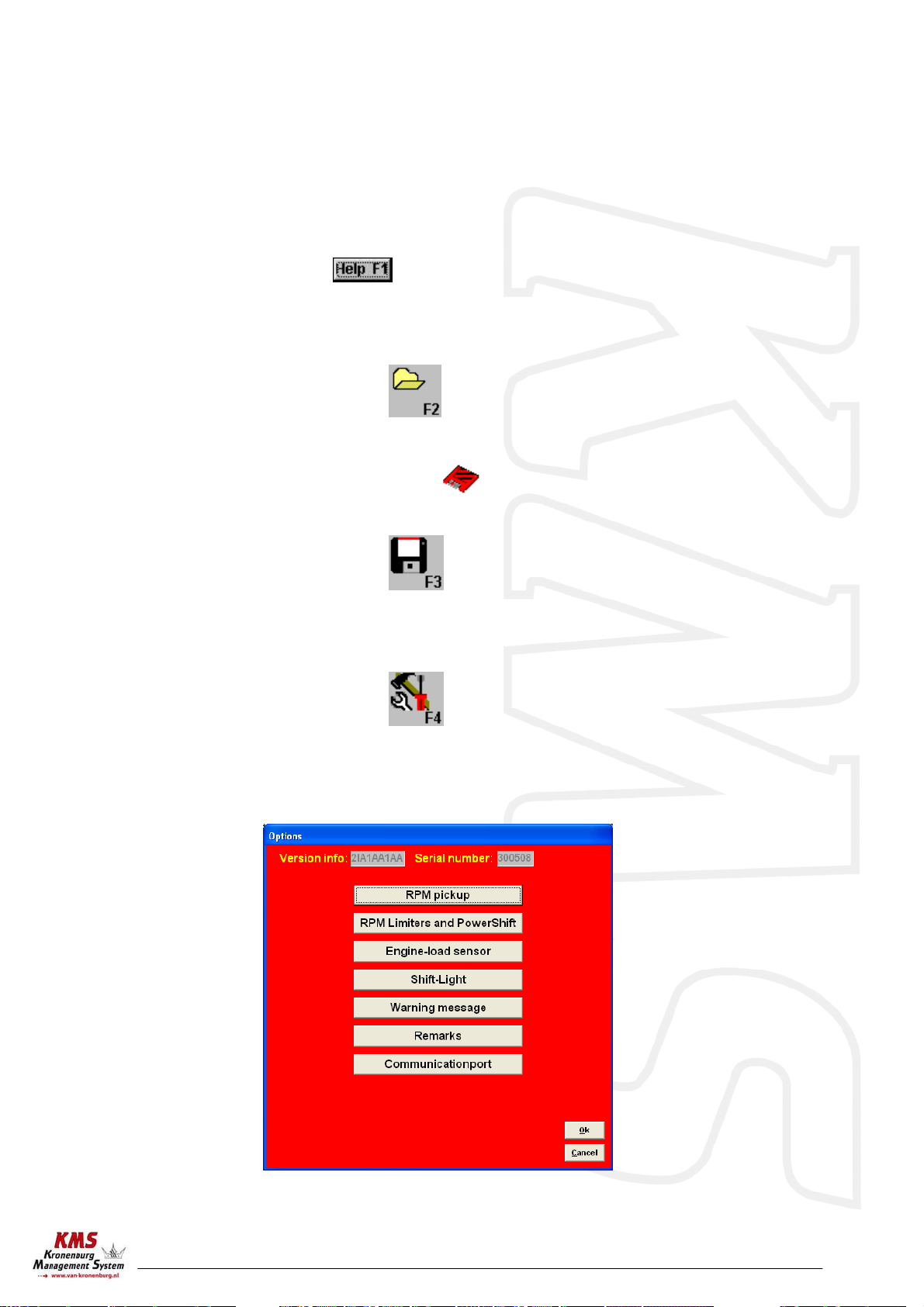

3.2 The function bar.....................................................................6

3.2.1 Function key F1 .................................................................6

3.2.2 Function key F2 .................................................................6

3.2.3 Function key F3 .................................................................6

3.2.4 Function key F4 .................................................................6

3.2.4.1 RPM pickup .................................................................7

3.2.4.2 RPM Limiters and Powershift ............................................8

3.2.4.3 Engine-load sensor ........................................................9

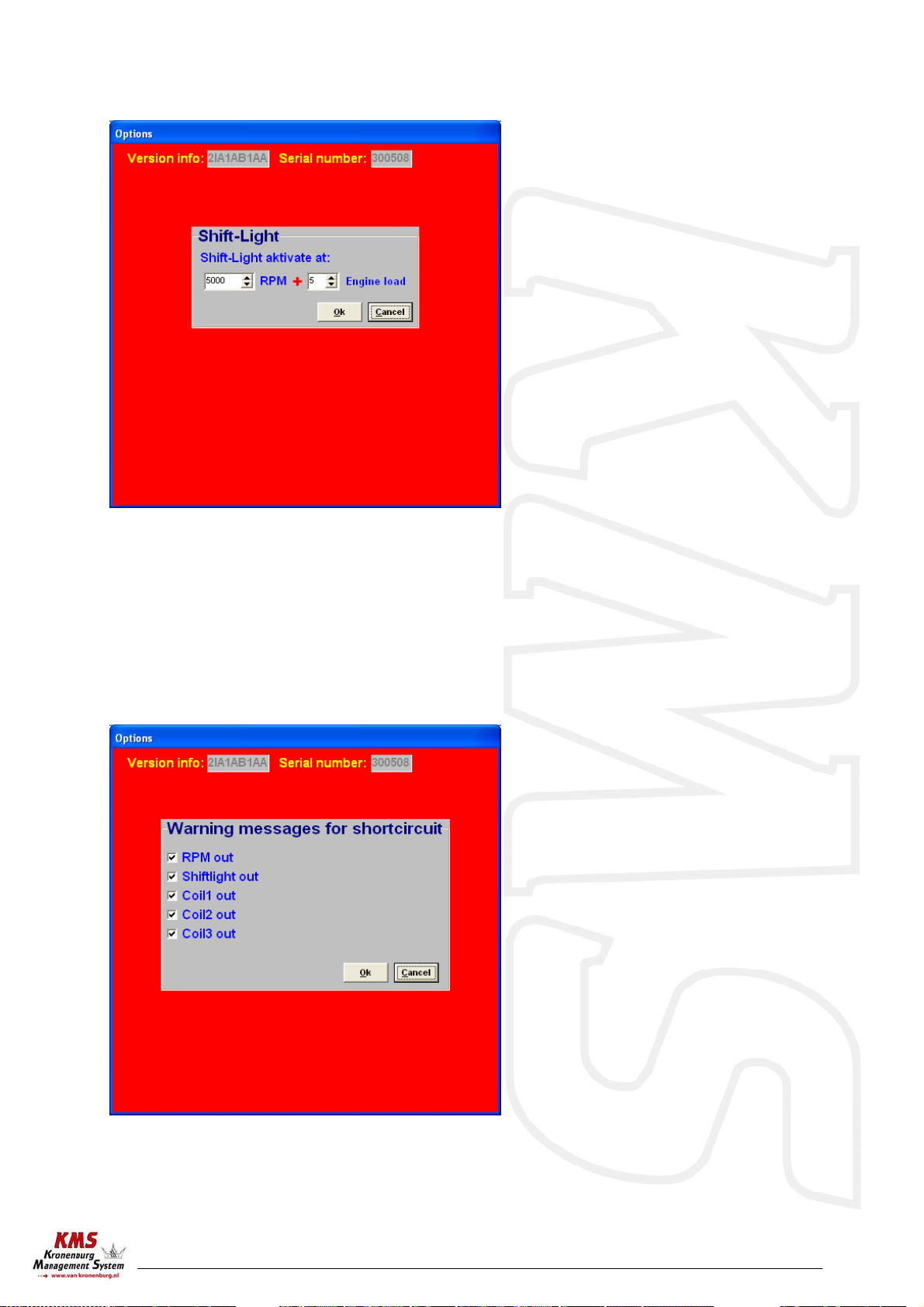

3.2.4.4 Shift-Light................................................................. 10

3.2.4.5 Warning message ........................................................ 10

3.2.4.6 Remarks................................................................... 11

3.2.4.7 Communicationport ..................................................... 11

3.2.5 Function key F6 ............................................................... 12

3.2.6 Function key F7 ............................................................... 12

3.2.7 Function key F10.............................................................. 13

3.3 The communication bar..........................................................14

4Programming.............................................................................15

4.1 Manual changing ...................................................................15

4.2 Bar charts ...........................................................................15

5Hardware installation .................................................................16

5.1 Fitting the ECU.....................................................................16

5.2 Connecting the communication cable.........................................16

6Fault tracing.............................................................................17

7Specifications............................................................................18

8Wiring Diagrams ........................................................................19

9Wiring examples ........................................................................21