KMS MA-5 manual

Version 5.1 2

Contents

1KMS (Kronenburg Management Systems).................................................................................................................... 3

2Software installation....................................................................................................................................................... 5

3KMS software.................................................................................................................................................................. 6

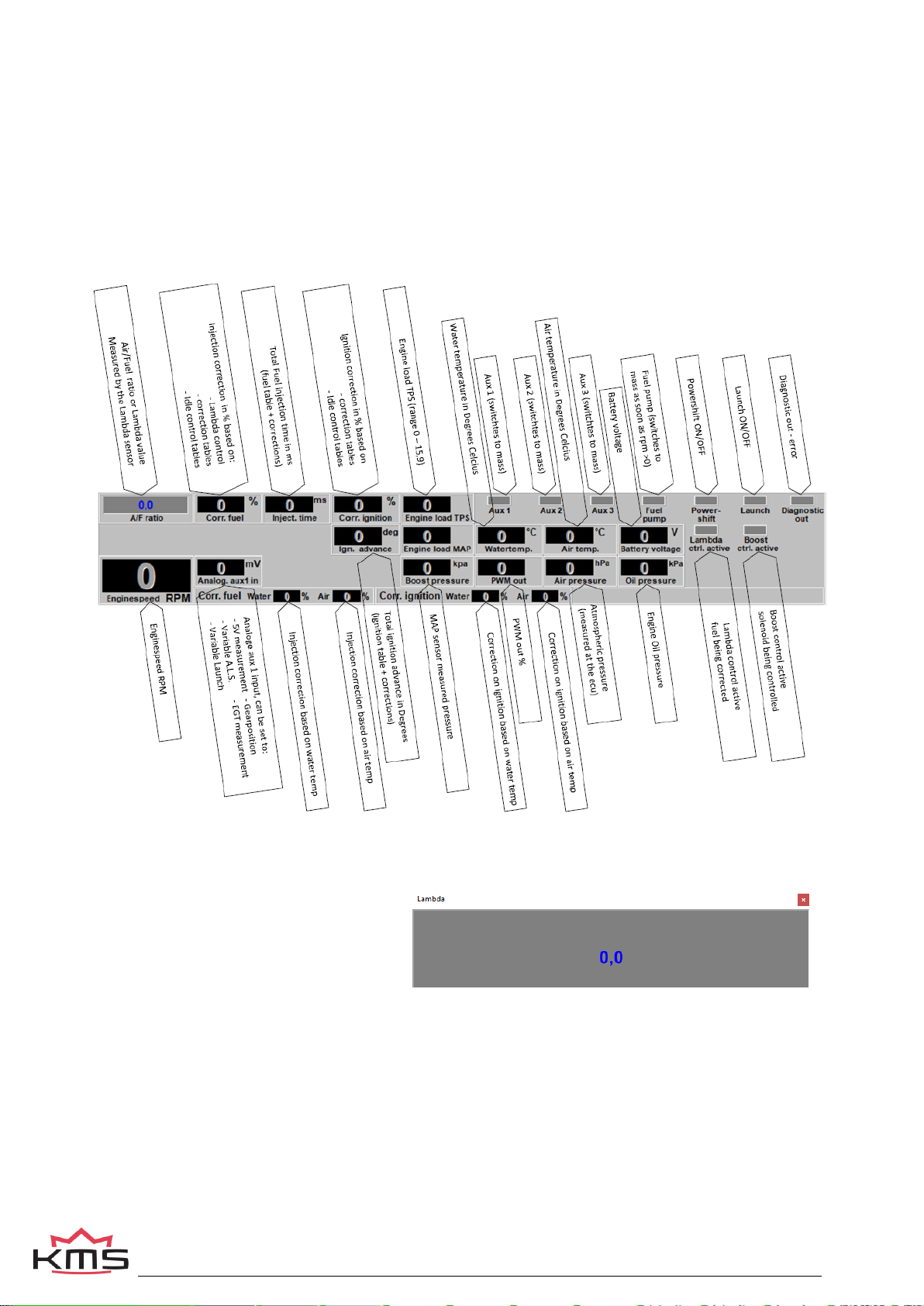

3.1 Main Screen.......................................................................................................................................................... 6

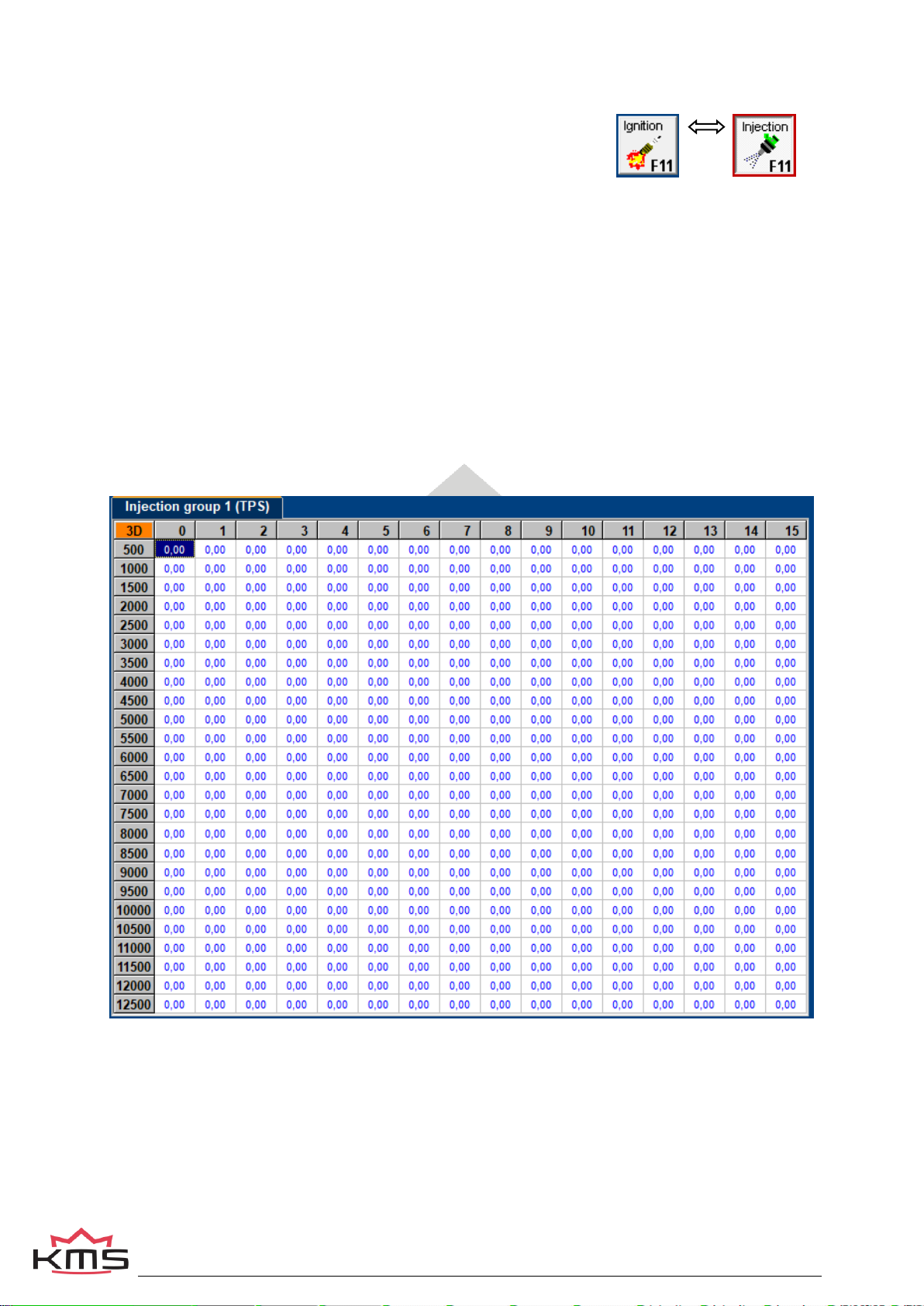

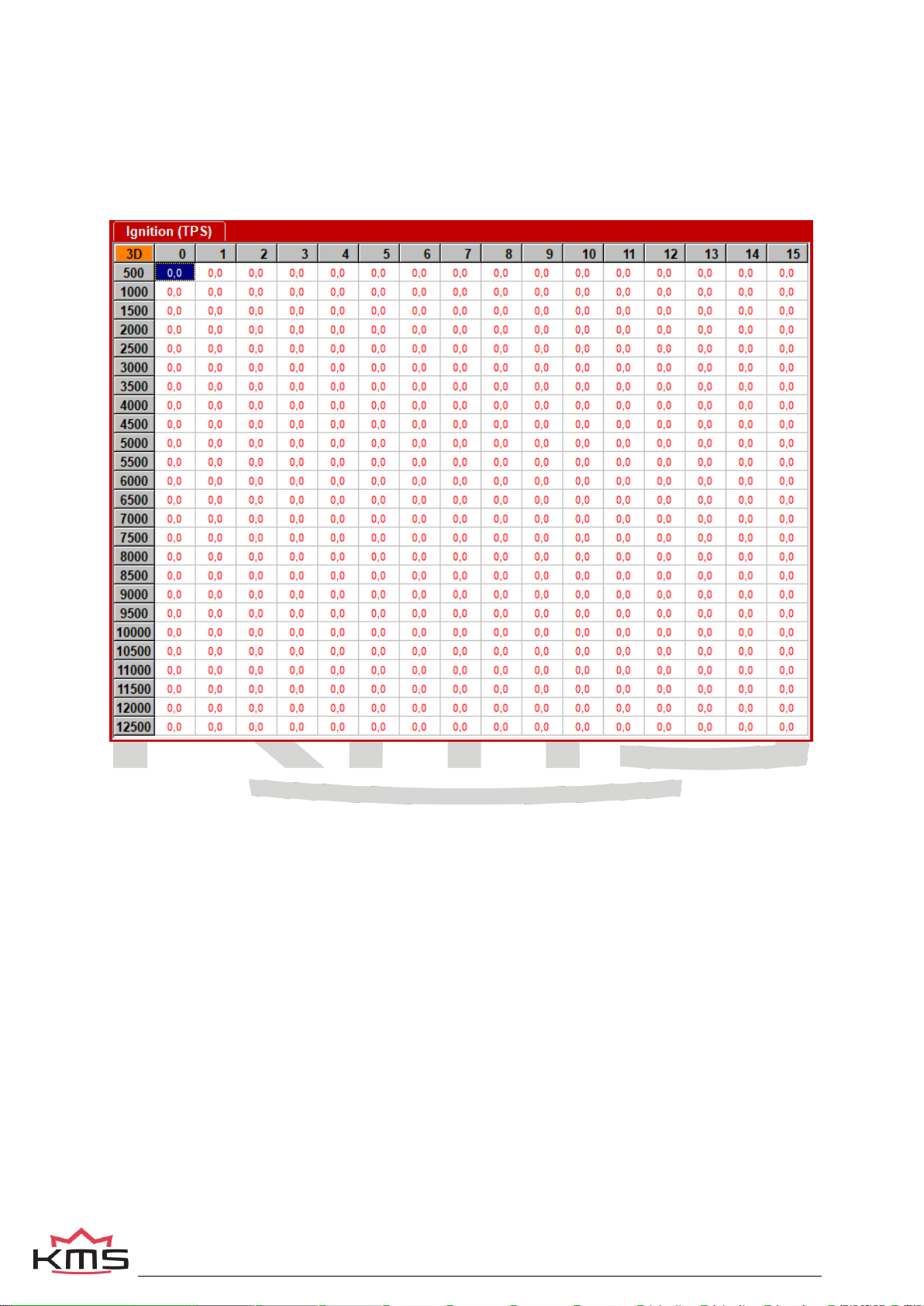

3.1.1 The Injection or Ignition table............................................................................................................................ 7

3.1.1.1 The injection characteristic diagram ....................................................................................................... 7

3.1.1.2 The ignition characteristic diagram......................................................................................................... 8

3.1.2 The communication bar .................................................................................................................................... 9

3.1.3 The function bar................................................................................................................................................ 9

3.2 Open file ............................................................................................................................................................. 10

3.3Save file.............................................................................................................................................................. 10

3.4 Options............................................................................................................................................................... 10

3.4.1 Options........................................................................................................................................................... 11

3.4.1.1 RPM pickup.......................................................................................................................................... 12

3.4.1.2 RPM limiters and PowerShift................................................................................................................ 16

3.4.1.3 Engine load sensor............................................................................................................................... 18

3.4.1.4 Start-up................................................................................................................................................ 22

3.4.1.5 Throttle pump effect ............................................................................................................................. 22

3.4.1.6 Interpol. to limits and Fuel cut............................................................................................................... 23

3.4.1.7 Hardware configuration ........................................................................................................................ 24

3.4.1.8 Lambda-control.................................................................................................................................... 25

3.4.1.9 Boost control........................................................................................................................................ 32

3.4.1.10 A.L.S.................................................................................................................................................... 37

3.4.1.11 AUX 1 .................................................................................................................................................. 38

3.4.1.12 AUX 2 .................................................................................................................................................. 38

3.4.1.13 AUX 3 ................................................................................................................................................. 38

3.4.1.14 External Dashboard............................................................................................................................. 39

3.4.1.15 Remarks.............................................................................................................................................. 40

3.4.1.16 Communication port............................................................................................................................. 40

3.4.2 Output test...................................................................................................................................................... 41

3.4.3 Crankshaft sensor test.................................................................................................................................... 41

3.4.4 Motor + system diagnostics ............................................................................................................................ 42

3.4.5 Change user access level............................................................................................................................... 45

3.5 Correction tables................................................................................................................................................ 46

3.6 Idle control ......................................................................................................................................................... 48

3.7 Up / down load function..................................................................................................................................... 49

3.8 Lambda function................................................................................................................................................ 49

3.9 Interpolation function ........................................................................................................................................ 49

3.10 Online / Offline ................................................................................................................................................... 50

3.11 Switch Injection/Ignition.................................................................................................................................... 51

3.12 Help..................................................................................................................................................................... 51

3.13 Communicationport........................................................................................................................................... 51

3.14 Shortcuts............................................................................................................................................................ 51

4Programming................................................................................................................................................................ 52

4.1 Manual changing boxes..................................................................................................................................... 52

4.2 Bar charts adjustment ....................................................................................................................................... 52

4.3 3D graph changing............................................................................................................................................. 53

4.4 Loading correction maps .................................................................................................................................. 53

5Hardware installation ................................................................................................................................................... 54

5.1 ECU specifications............................................................................................................................................. 55

6Troubleshooting ........................................................................................................................................................... 56

7Specifications............................................................................................................................................................... 59

8Appendix 1: Trigger pattern drawings......................................................................................................................... 60