Page 10 of 40 0901034 Rev: REL (09/13)

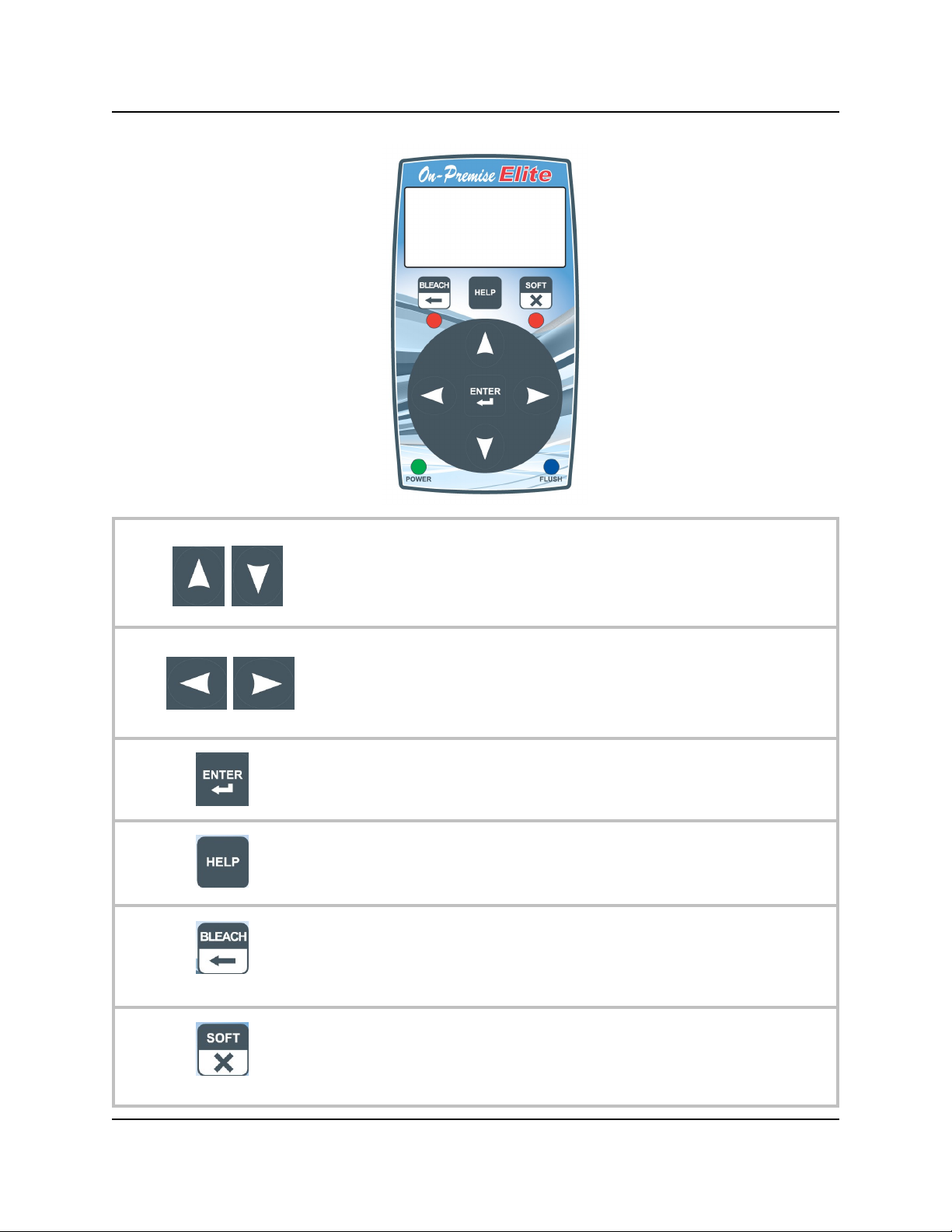

Use ▲/▼ buttons to move cursor to system settings and push

ENTER to open system settings menu options. Use ▲/▼

buttons again to move cursor through system settings options and

press ENTER to edit that option.

SYSTEM SETTINGS

This selection allows the ―main‖ access code to be

changed. The main access code allows entry into the

programming menus as well as report functions. Use the

▲/▼ buttons to change each individual number column

and ◄/► buttons to move the cursor to the next number

column. Once the new code number is set, then press

ENTER to continue.

NOTE: If the access code is changed, keep a record of the

new code in a safe place. If the new code is forgotten,

contact Knight.

CHANGE MAIN CODE

This selection allows the washer id number to be changed.

Use the ▲/▼ buttons to change each individual number

column and ◄/► buttons to move the cursor to the next

number column. Once the id number has been set, then

press ENTER to save.

WASHER ID

This selection allows the user access code to be changed.

Use the ▲/▼ buttons to change each individual number

column and ◄/► buttons to move the cursor to the next

number column. Once the new code number is set, then

press ENTER to save access code.

NOTE: The user access code allows access to a limited

number of menu selections.

CHANGE USER CODE

This selection allows the dispenser id number to be

changed. Use the ▲/▼ buttons to change each individual

number column and ◄/► buttons to move the cursor to the

next number column. Once the id number has been set,

then press ENTER to save the setting into memory.

NOTE: Set your dispenser IDs so that they correspond with

the washer numbers.

DISPENSER ID

This selection allows you to choose between US or Metric

units of measure. Use the ◄/► buttons to select the unit of

measure, then press ENTER to save.

UNITS OF MEASURE

This selection allows the washer name to be changed. Use

the ▲/▼ buttons to change each individual letter/number

column and ◄/► buttons to move the cursor to the next

letter/number column. Once the washer name has been

set, then press ENTER to save.

EDIT WASHER NAME