rev. 02.04.2020 © KÖBER SRL VADURI BRANCH

KÖBER S.R.L.

VADURI BRANCH

INSTALLATION AND USE MANUAL

NAME OF APPARATUS / EQUIPMENT

DOMESTIC HOT WATER STORAGE TANK

CONTENT

1GENERAL.............................................................................................................................................................. 4

1.1 Applicable standards and directives....................................................................................................................................4

2GENERAL PRESENTATION OF THE PRODUCT....................................................................................................... 4

2.1 Use according to specifications............................................................................................................................................4

2.2 Advantages............................................................................................................................................................................4

2.3 Components...........................................................................................................................................................................4

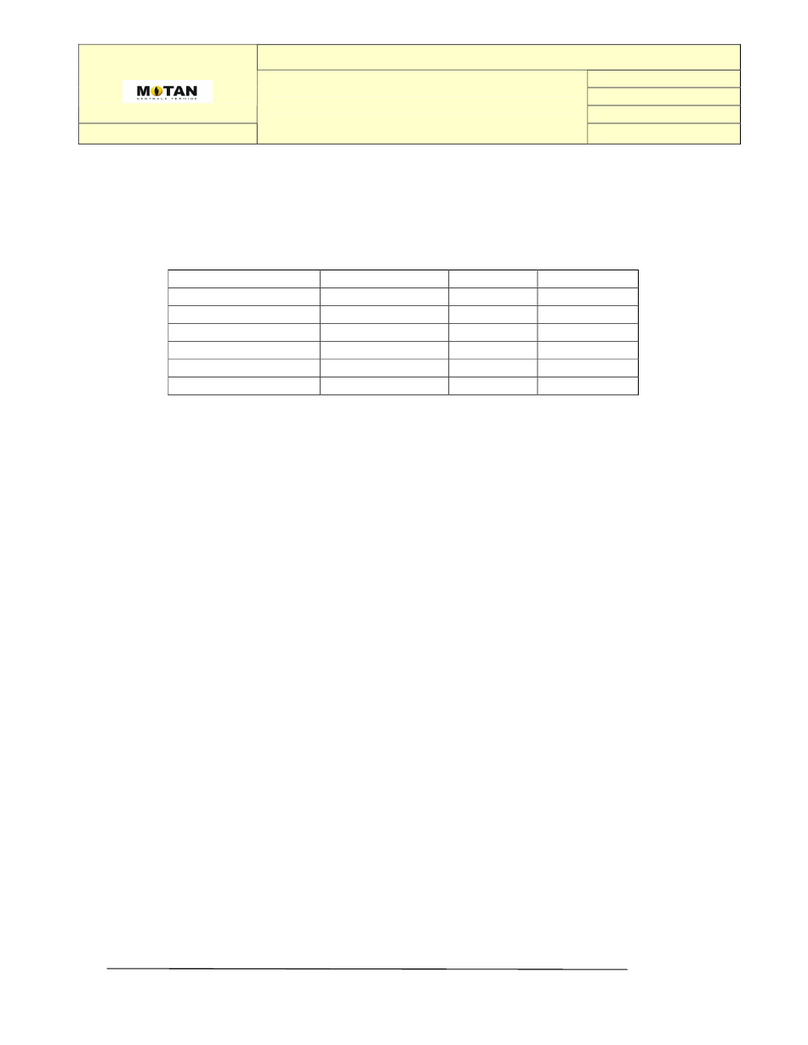

2.4 Technical data........................................................................................................................................................................5

2.4.1 Dimensional and constructive characteristics.....................................................................................................................5

2.4.2 Functional characteristics......................................................................................................................................................6

2.5 Design indications...................................................................................................................................................................7

2.5.1 Boiler principle diagram.........................................................................................................................................................7

2.5.2 Boiler operational modes.......................................................................................................................................................7

2.6 Boiler equiped with Mixing valve kit......................................................................................................................................8

3INSTALLATION INSTRUCTION............................................................................................................................... 9

3.1 Transport to the mounting place...........................................................................................................................................9

3.2 Installation.............................................................................................................................................................................10

3.2.1 Wall mounting.......................................................................................................................................................................10

3.2.2 Boiler connection .................................................................................................................................................................10

3.2.3 Filling the boiler with water ..................................................................................................................................................13

3.2.4 Emptying the boiler ..............................................................................................................................................................13

3.2.5 Electrical diagram................................................................................................................................................................14

4USE INSTRUCTIONS............................................................................................................................................. 15

4.1 Boiler startup..........................................................................................................................................................................15

4.2 Indications regarding boiler decommissioning..................................................................................................................16

5MAINTENANCE .................................................................................................................................................. 16

5.1 Boiler cleaning ......................................................................................................................................................................16

5.2 Anode checking...................................................................................................................... Error! Bookmark not defined.

5.3 Replacing the anode.............................................................................................................. Error! Bookmark not defined.

5.4 Checking heater ..................................................................................................................................................................17

5.5 Checking the hydraulic safety group.................................................................................................................................17

5.6 External cleaning..................................................................................................................................................................17

6DISPOSING OF OLD ELECTRICAL AND ELECTRONIC APPLIANCES (DIRECTIVE 2002/96/EC –DEEE)............ 17

7SPARE PARTS ...................................................................................................................................................... 18

8RECORDS OF INTERVENTIONS........................................................................................................................... 20