Kontakt:

Zittauer Straße 12 Tel. + 49 35844/ 70234 www.elektromaschinen-koci.de

List of content

1. Introduction .................................................................................................................................. 1

1.1 Owner’s responsibility .............................................................................................................. 1

1.2 Copyright .................................................................................................................................. 1

1.3 General advices ....................................................................................................................... 1

EC – Declaration of Conformity ..................................................................................................... 1

2. Warranty and complaints ............................................................................................................ 2

3. Reference of utilization ................................................................................................................ 2

3.1 conventional utilization ............................................................................................................. 2

3.2 unconventional utilization ......................................................................................................... 2

4. Technical information about the compressor unit ................................................................... 3

4.1 Components account ............................................................................................................... 3

4.2 Technical description ............................................................................................................... 3

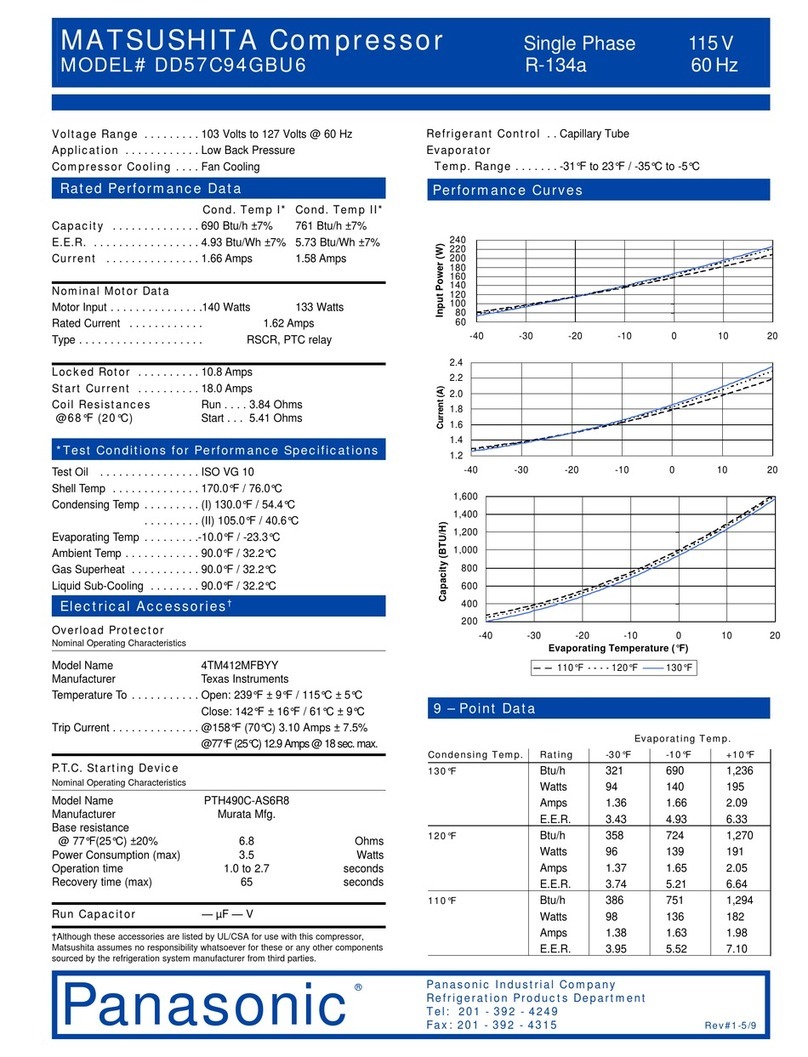

4.3 Technical Data ......................................................................................................................... 4

5. Commissioning ............................................................................................................................ 5

5.1 Location and assembly references .......................................................................................... 5

5.2 Installation – electrical ............................................................................................................. 6

6. Maintenance.................................................................................................................................. 8

General reference notes ................................................................................................................ 9

Compressor block .......................................................................................................................... 9

Cylinder head and valves .............................................................................................................. 9

Clean and replace air filter ............................................................................................................. 9

Maintenance of the bearings and carbon brushes of the DC motor .............................................. 9

Checking the safety valve ............................................................................................................ 10

Pressure container (accessory if requested) ............................................................................... 10

Performance check ...................................................................................................................... 10

Torque specification ..................................................................................................................... 10

Reference notes to anti-freeze pump .......................................................................................... 11

7. Safety regulations – environment protection .......................................................................... 11

7.1 Safety regulations .................................................................................................................. 11

7.2 Environment protection .......................................................................................................... 11

8. Troubleshooting ......................................................................................................................... 12

9. Storing & Transport ................................................................................................................... 13

10. Replacement parts ................................................................................................................... 13