Kodak PAGEANT 250S User manual

Other Kodak Projector manuals

Kodak

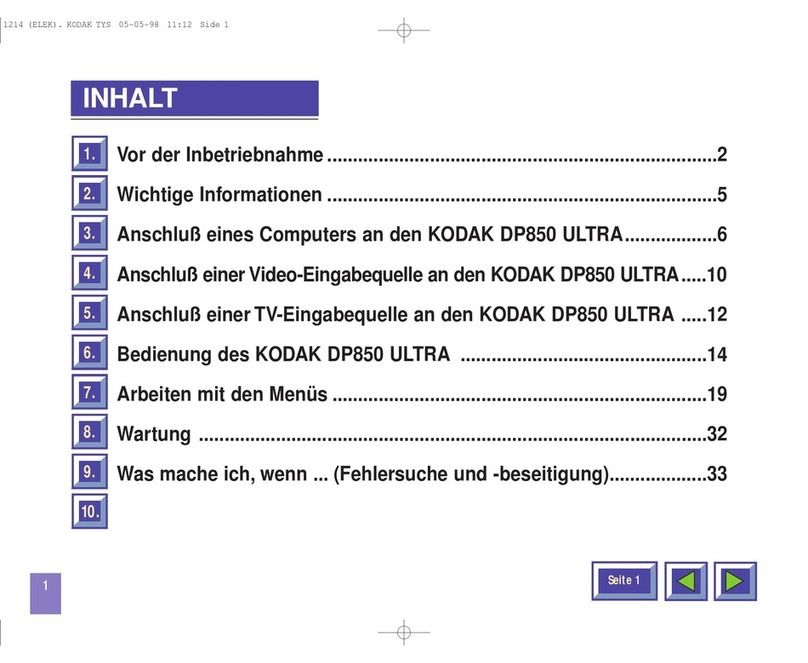

Kodak DP850 - Ultra Digital Projector Quick start guide

Kodak

Kodak Ektagraphic III AFT User manual

Kodak

Kodak EKTAPRO User manual

Kodak

Kodak LUMA 350 User manual

Kodak

Kodak Ektapro 4020 User manual

Kodak

Kodak Carousel 4200 User manual

Kodak

Kodak Carousel S-AV 2050 Operating manual

Kodak

Kodak EKTAGRAPHIC III User manual

Kodak

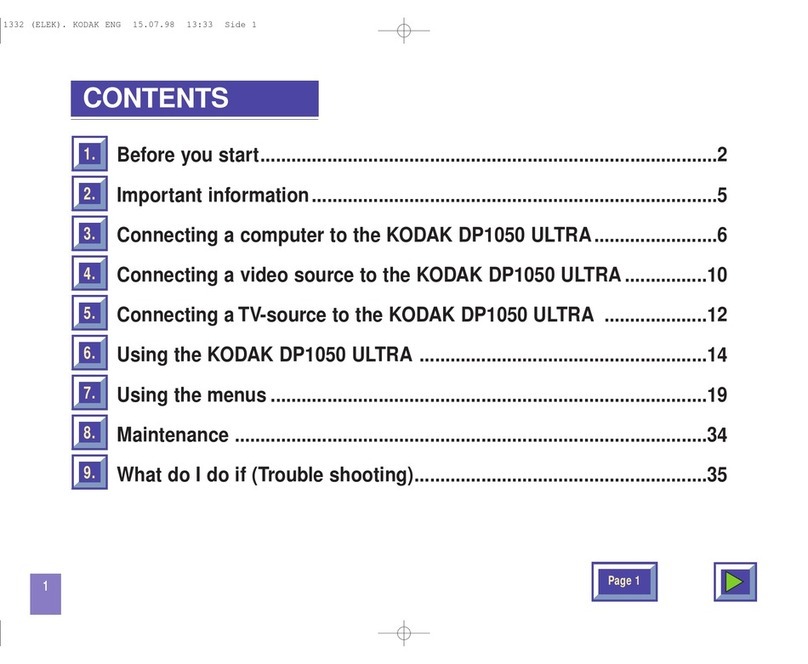

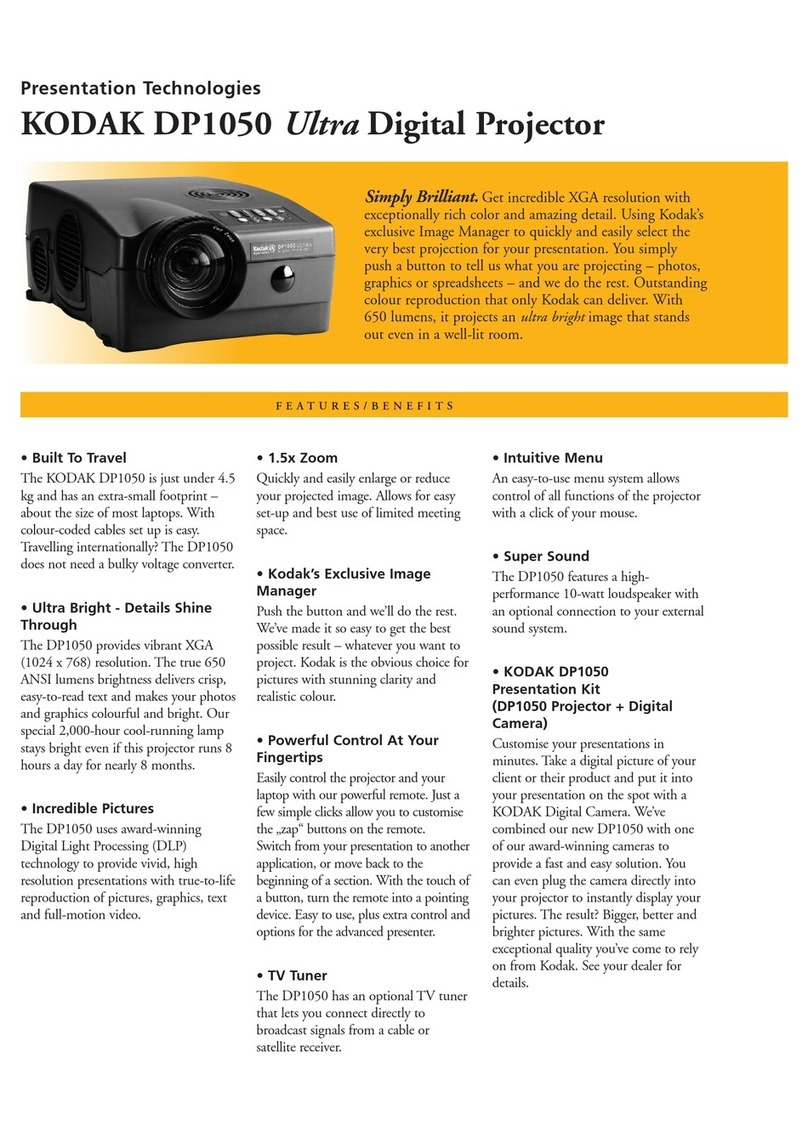

Kodak DP1050 ULTRA User manual

Kodak

Kodak V600 User manual

Kodak

Kodak EKTAPRO 9020 CINE User manual

Kodak

Kodak DP1050 ULTRA Installation and operation manual

Kodak

Kodak Ektalite 500 User manual

Kodak

Kodak Brownie A15 User manual

Kodak

Kodak EKTAGRAPHIC AFT User manual

Kodak

Kodak EKTAGRAPHIC User manual

Kodak

Kodak DP800 - Digital Projector Operating instructions

Kodak

Kodak Luma 75 User manual

Kodak

Kodak EKTAGRAPHIC 220 User manual

Kodak

Kodak Carousel S-AV 2060 User manual