❷❶

M020961

Ver.1.0

Ver. 1.0

Instruction Manual

ZL2

注:cタイプの使用サイズは左右 50mm未満

このデータからの縮率は50%より小さく

Linear Magnetic Sensor Controller Long Type

Thank you for purchasing this Koganei product.

Before using it, be sure to read this manual and make sure you use it correctly.

Keep this manual in a safe place for future reference.

Specications

Connector number

●Sensor head

Connector side number

Signal name Lead wire color

1Sensor head voltage (+) Sensor head brown lead

2Sensor head voltage output A_IN Sensor head white lead

3Sensor head voltage output B_IN Sensor head black lead

4Indicator (LED) input Sensor head red lead

5GND Sensor head blue lead

6Sensor head voltage output C_IN Sensor head yellow lead

●Power supply

Pin No. Signal name Lead wire color

1Power supply voltage input (24 V) Brown

2Analog output (1 to 5V) Gray

3

Effective measuring range signal output (STABI)

Black

4GND Blue

5Switch output OUT1 White

6Switch output OUT2 Red

7Switch output OUT3 Green

8Switch output OUT4 Yellow

●Sensor head

Item Model ZLL□-□L

Power supply voltage 5 VDC±5%

Consumption current 20 mA max.

Mounting methods Body embedded type (ZLL1, ZLL2), □4 type (ZLL3)

Operation indicator light Red LED lights at optimal sensitivity position (Operation position can be changed by setting.)

Lead wire Heat-resistant, oil-resistant vinyl sheath instrumentation cable φ2.8 6 core With 6P connectors

Insulation resistance 100 MΩ MIN. (500 VDC Megger, between case and lead wire terminal)

Withstand voltage 500 VAC (50/60 Hz) in 1 minute (between case and lead wire terminal)

Shock resistance 294.2 m/s2(non repetitive)

Protective structure IP67

Vibration resistance 88.3 m/s2(Double amplitude: 1.5 mm 10 ~ 55 Hz)

Ambient temperature 0 to 50℃ (non-condensation, non-freezing)

Storage temperature range -10 to 70℃ (non-condensation, non-freezing)

Mass 20 g (When 1L lead wire length is 1000 mm.)

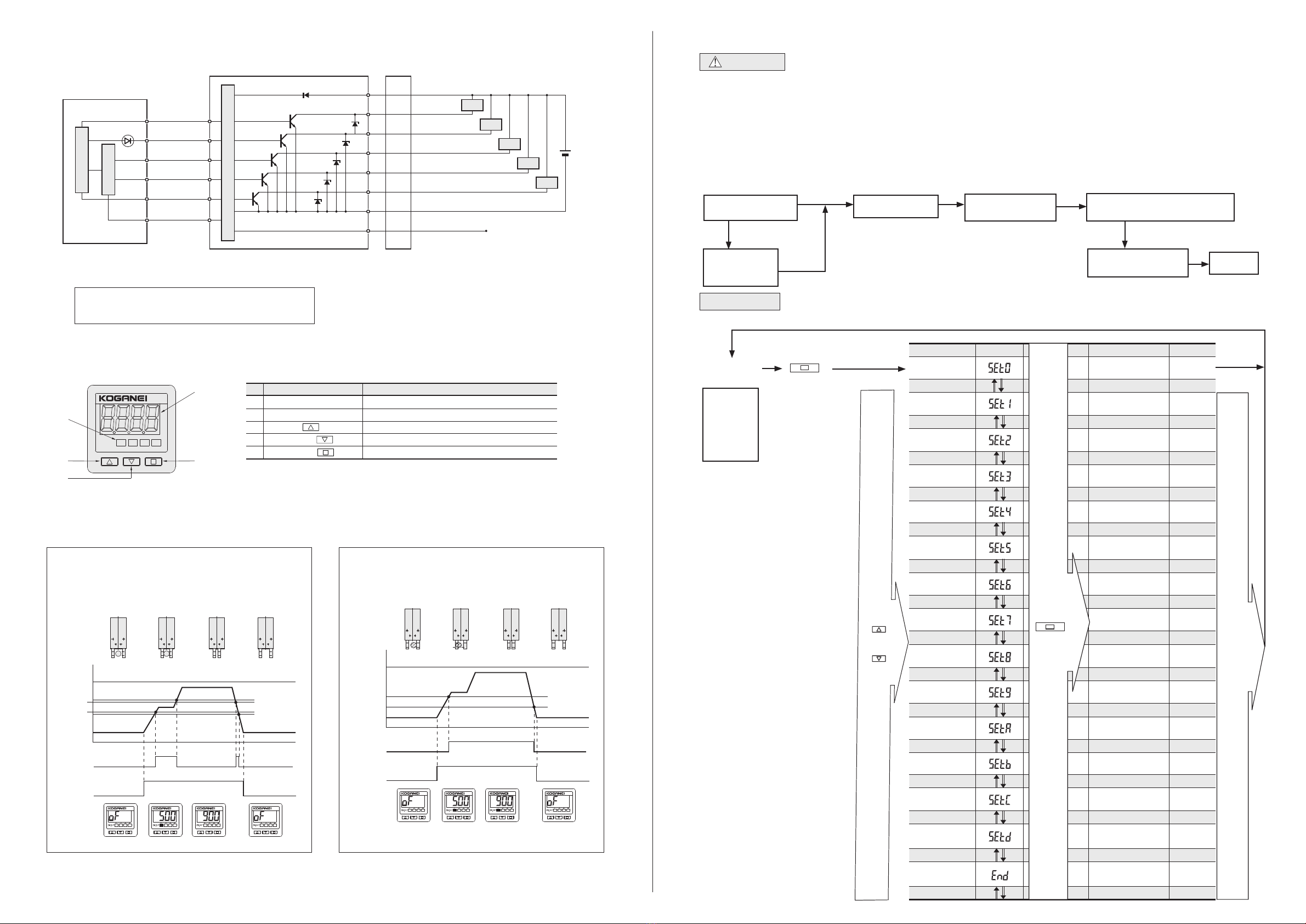

Sensor head and connector connection overview

The ZLL-□-□Lsensor head is provided to you with the mini

plug wire mount plug connected to the sensor head unit. A

special tool is required if you need to reconnect in order to adjust

the length. Use the following procedure when reconnecting.

1. Be sure to use the mount plug and the special tool shown

below when reconnecting.

6P mini clamp wire mount plug Model: ZL-6M

Special tool Model: 1729940-1

Tyco Electronics Japan G.K.

2.

Check to make sure that the connector cover (lead wire inlet) is

sitting above the body of the connector. Note that a connector

whose cover is even with the body of the connector cannot be used.

3. Cut the sensor head cable to the required length.

Strip the outer covering of the cable, 50 mm from the end, to

expose the lead wires. Do not strip the insulation from the

individual lead wires at this time.

4. Insert the lead wires into the connector cover holes in

accordance with the information in the table below. Check to

make sure the lead wires are fully inserted (wire goes in about

9 mm) as far as they will go by viewing the semi-transparent

top cover of the connector.

Note that supplying power while connections are incorrect will

damage the sensor head and controller.

Connector side number

Signal name Lead wire color

1Sensor head voltage (+)

Sensor head brown lead

2

Sensor head voltage output A_IN

Sensor head white lead

3

Sensor head voltage output B_IN

Sensor head black lead

4Indicator (LED) input Sensor head red lead

5GND Sensor head blue lead

6

Sensor head voltage output C_IN

Sensor head yellow lead

5. Taking care not to allow the lead wires to come out of the

connector, use the special tool (don't try to use any other tool)

to squeeze the cover and body of the connector until the

cover is pressed into the body.

Connection is complete when the cover is even with the

connector body.

6. Double check to make sure that wiring is correct.

654321

Sensor head

Red Black White Brown

654321

Sensor head

Yellow Blue

Attaching and detaching of the sensor head and power/switch cables

To attach the sensor head and the power/switch cables, position

the lock levers as shown in the illustration above, and then insert

until they lock into place with the controller side connectors. To

disconnect, press the lock lever down as far as it will go as you

pull the connector to unplug it. At this time, take care not to apply

undue force to the lead wires.

Attaching the protective front cover

Attach the protective front cover so the tabs inside the cover

enter the slots on the Linear Magnetic Sensor Controller.

* To remove the protective front cover, hook your finger on the

projection on one side of the cover and remove it.

Sensor head installation precautions

1.

After inserting the sensor head into the Air Hand or cylinder

switch mounting groove (depending on which you are using) and

move the sensor head to the suitable position, secure it in place

with the fixing screw. Use a tightening torque of 0.2 N·m or less.

2.

For information about the sensor head insertion direction, see the "Sensor

switch mounting method" for the Air Hand or cylinder you are using.

3.

When the sensor head is installed in a position that causes it to

protrude from the Air Hand or cylinder body you are using, the sensor

head will move by the amount of the gap with the sensor groove,

which will cause deterioration of sensing precision. Affix insulating

tape or some other suitable material to the lower part of the sensor

head (as shown in the illustration below) in order to reduce the gap.

Protective front cover (available separately)

ZLBK100

Slot

Tab

Projection

Installation

Do not use this product for the purpose of accident prevention or

for other safety assurance purposes. Using the product in any of

the ways described above creates the risk. of loss of human life.

DANGER

●Controller

Item Model ZL2

Power supply voltage 24 VDC ±10%

Consumption current 50 mA max. (Not including supply power to sensor.)

Sensor input supply power and voltage 5 VDC

Sensor input maximum input voltage 3.0 V

Switch output method NPN open collector output, 5 points

Load voltage 30 VDC

Load current 50 mA max.

Switch output volume repeatability ±1%F.S. ±1 digit Note

Internal voltage drop 0.3 V MAX. (When Ic = 5 mA)

Response time 5 ms MAX.

Operation indicator light Lights red when each switch output is on.

Value display 1/1000 division display within effective measuring range(4 digits, 2-color display: red and green)

Analog output voltage range DC1 to 5V within effective measuring range, DC0.8V outside effective measuring range (1kΩ output impedance)

Analog output repeatability ±1% of F.S (25℃±5℃) Note

Insulation resistance 100 MΩ MIN. (500 VDC Megger, between case and lead wire terminal)

Withstand voltage 500 VAC (50/60 Hz) in 1 minute (between case and lead wire terminal)

Shock resistance 294.2 m/s2(non repetitive)

Ambient temperature 0 to 50℃ (non-condensation, non-freezing)

Storage temperature range -10 to 70℃ (non-condensation, non-freezing)

Mass 40 g

Note: This performance excludes the mechanical looseness of a cylinder with a fixed magnet (standalone performance). In the case of a movable type cylinder whose magnet

is not fixed, the movable part and repeatability are degraded.

1 2 3 4

ZL2

SW.OUT

654321

Brown

White

Black

Red

Blue

Yellow

Lock lever

Lock lever

8

7

6

5

4

3

2

1

Power/switch cable

ZLW-3L

Sensor head

ZLL□-□L

Insulation tape cutting dimensions

(reference values)

Large amount of free

movement

15

2

When sensor head is installed so it

protrudes from the Air Hand

Countermeasure: Affix

something like insulation

tape and then insert into

the sensor groove to

reduce movement.