2TT-1701 2/17

Safety Precautions

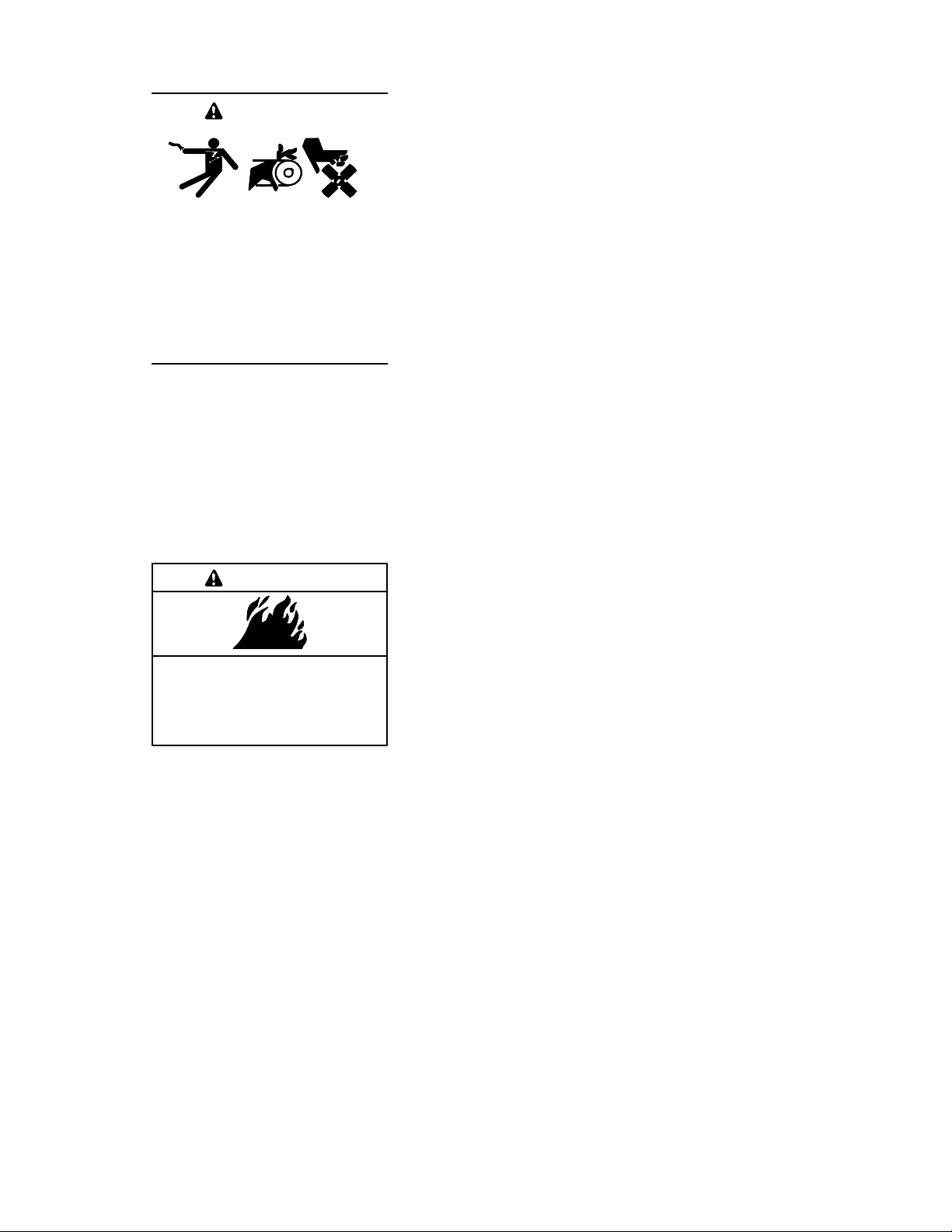

Accidental starting.

Can cause severe injury or death.

Disconnect the battery cables before

working on the generator set.

Remove the negative (--) lead first

when disconnecting the battery.

Reconnect the negative (--) lead last

when reconnecting the battery.

WARNING

Disabling the generator set. Accidental starting can

cause severe injury or death. Before working on the

generator set or equipment connected to the set, disable the

generator set as follows: (1) Press the generator set off/reset

button to shut down the generator set. (2) Disconnect the

power to the battery charger, if equipped. (3) Remove the

battery cables, negative (--) lead first. Reconnect the negative

(--) lead last when reconnecting the battery. Follow these

precautions to prevent the starting of the generator set by the

remote start/stop switch.

Fire.

Can cause severe injury or death.

Do not smoke or permit flames or

sparks near fuels or the fuel system.

WARNING

Servicing the fuel system. A flash fire can cause severe

injury or death. Do not smoke or permit flames or sparks near

the fuel injection system, fuel line, fuel filter, fuel pump, or other

potential sources of spilled fuels or fuel vapors. Catch fuels in

an approved container when removing the fuel line or fuel

system.

Installation Procedure

1. Remove the generator set from service.

1.1 Press the generator set OFF/RESET button to

shut down the generator set.

1.2 Disconnect the power to the battery charger, if

equipped.

1.3 Disconnect the generator set engine starting

battery(ies), negative (--) lead first.

1.4 If equipped with an enclosure, remove enclosure

doors as needed to service the engine.

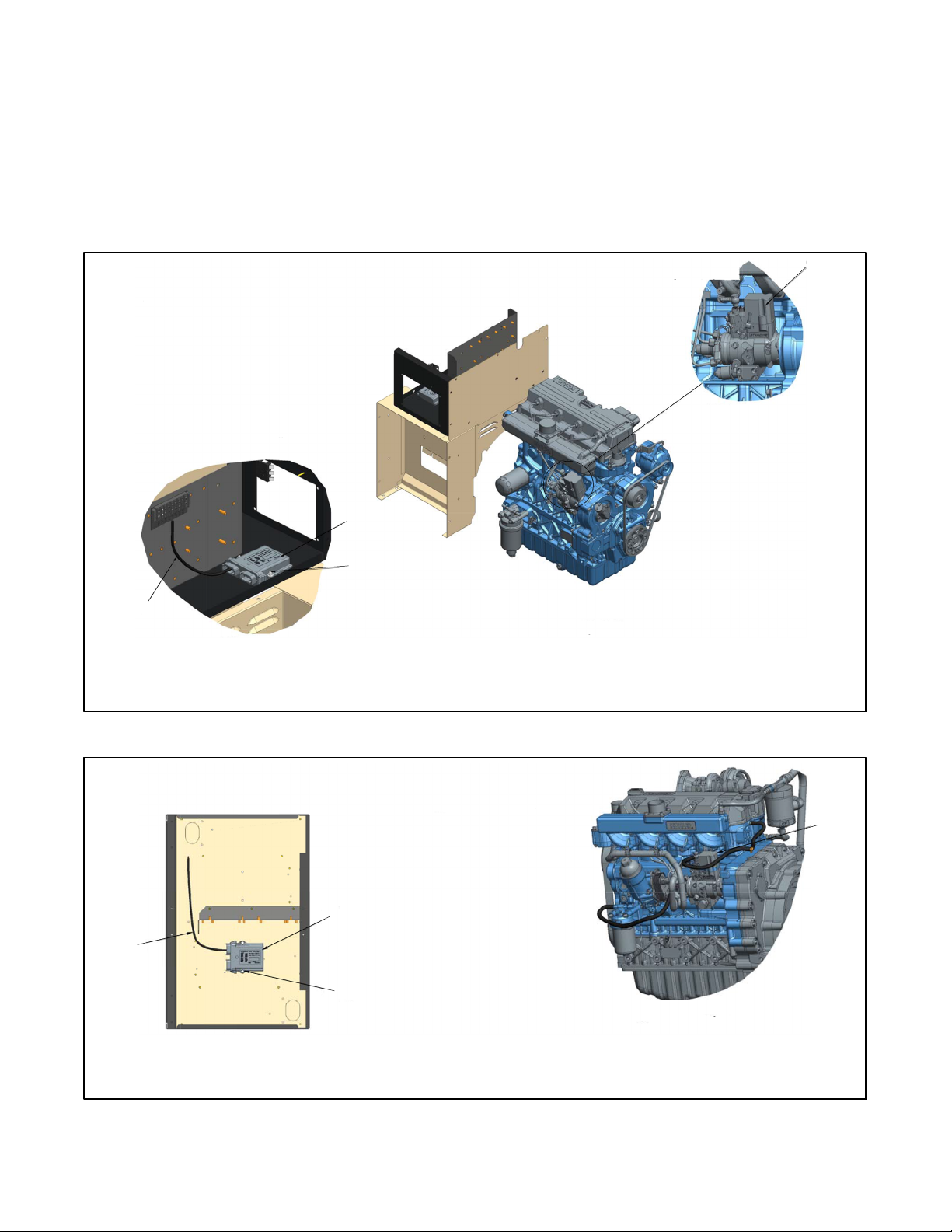

2. Install the actuator.

2.1 Before removing the mechanical governor head and

replacing it with the actuator (324516), clean the

surrounding area. Clean outside of the fuel injection

pump with dry compressed air before removing the

governor control cover. Place a suitable container

underneath the fuel injection pump to catch any fuel

that may spill when removing the governor control

cover.

Note: Dispose of all waste materials (engine oil, fuel,

filter, etc.) in an environmentally safe manner and

in accordance with all applicable laws.

2.2 Remove lead 70 from the existing mechanical

governor and tape the end of the lead and tuck

inside the plastic conduit.

2.3 Remove the fuel return line and the return line

connector assembly from the governor cover using

care not to allow dirt to enter the injection pump.

Remove and discard the return line connector

O-ring. Set aside the return line connector.

2.4 Loosen the three cover screws.

Note: A universal joint or flex socket is needed to

remove the rear-most screw.

2.5 Remove the governor control cover assembly (see

the following NOTE). Save the screws for later use.

See Figure 3.

Note: When the actuator is fully loose, have rags handy

as there will be fuel spilled from the reservoir.

Figure 4 shows the fuel rack/metering assembly

with the cover removed. The fork on the

electronic governor cradles this arm and moves it

to govern the speed. On a mechanical governor,

the solenoid defaults to an extended position

when not powered so that it pushes against the

spring tension; this metering assembly turns off

fuel. Take great care when replacing the

actuator. If the linkage is missed, the engine may

“runaway” as it would be in the full-fuel position. If

you push on this arm with your finger, you’ll see it

actuate and feel the tension.