TT-1710 6/17b

INSTALLATION INSTRUCTIONS

Original Issue Date: 11/16

Model: 20--200 kW with Fast-ResponserXAlternator

Market: Industrial, Residential/Commercial, and Marine

Subject: FRX Activator Service Kit GM101821-S

Introduction

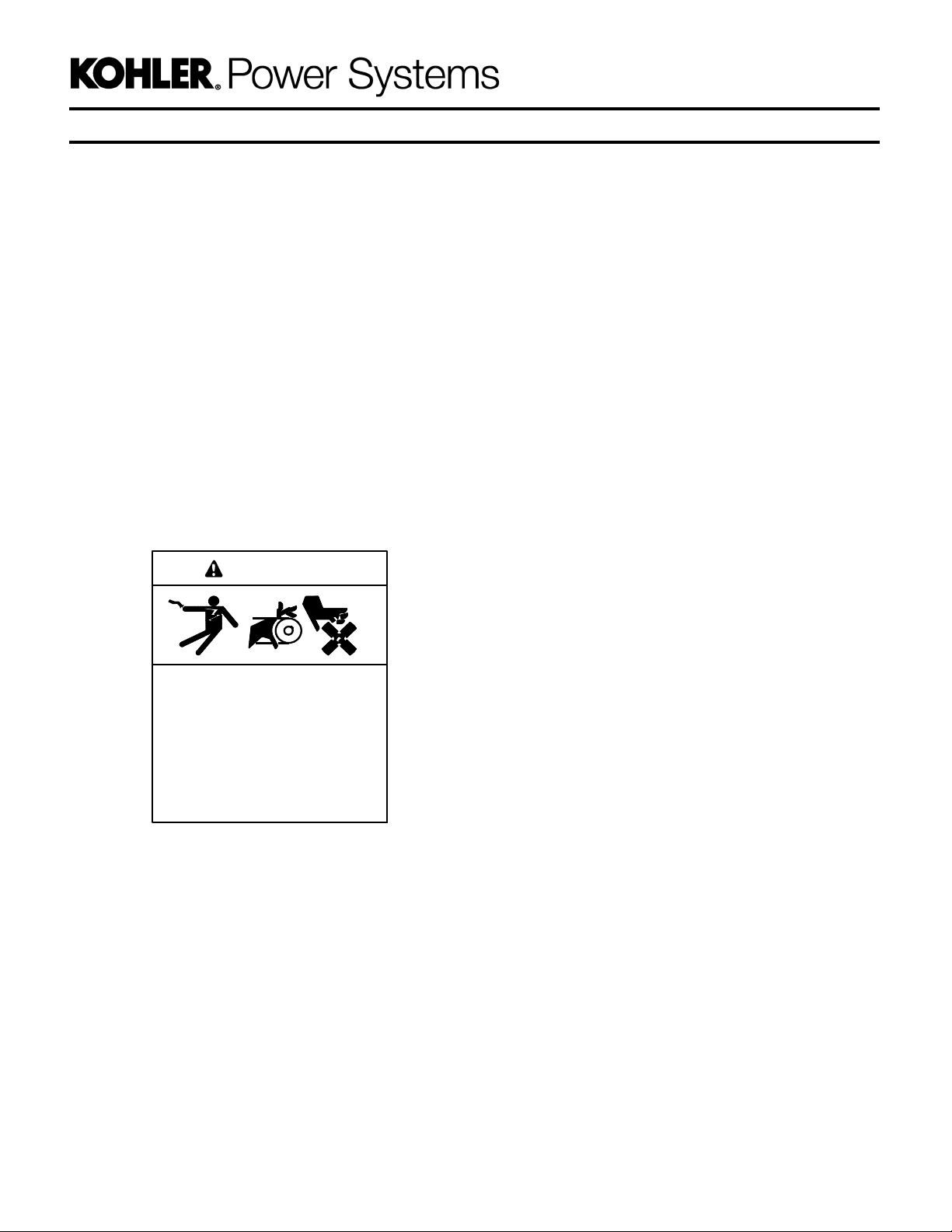

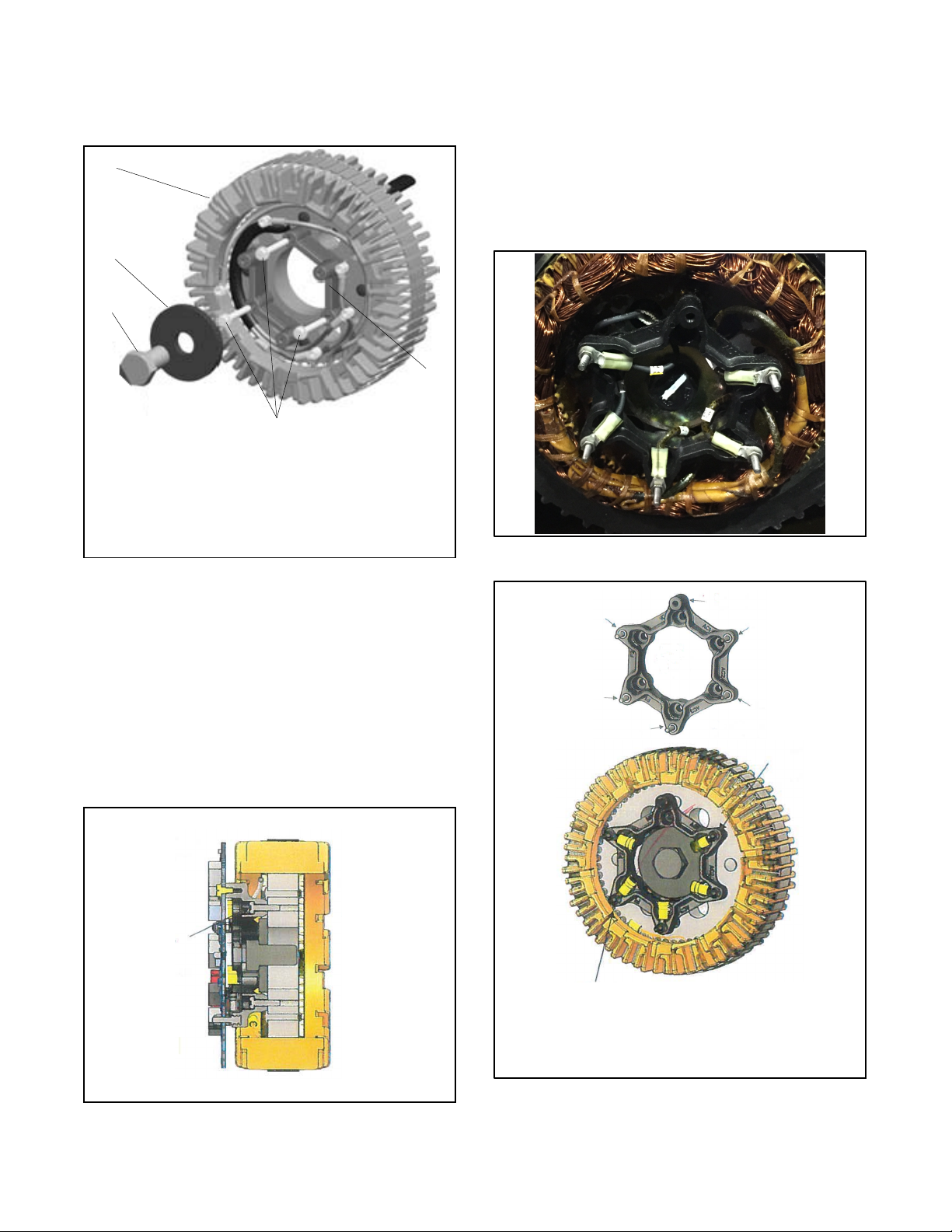

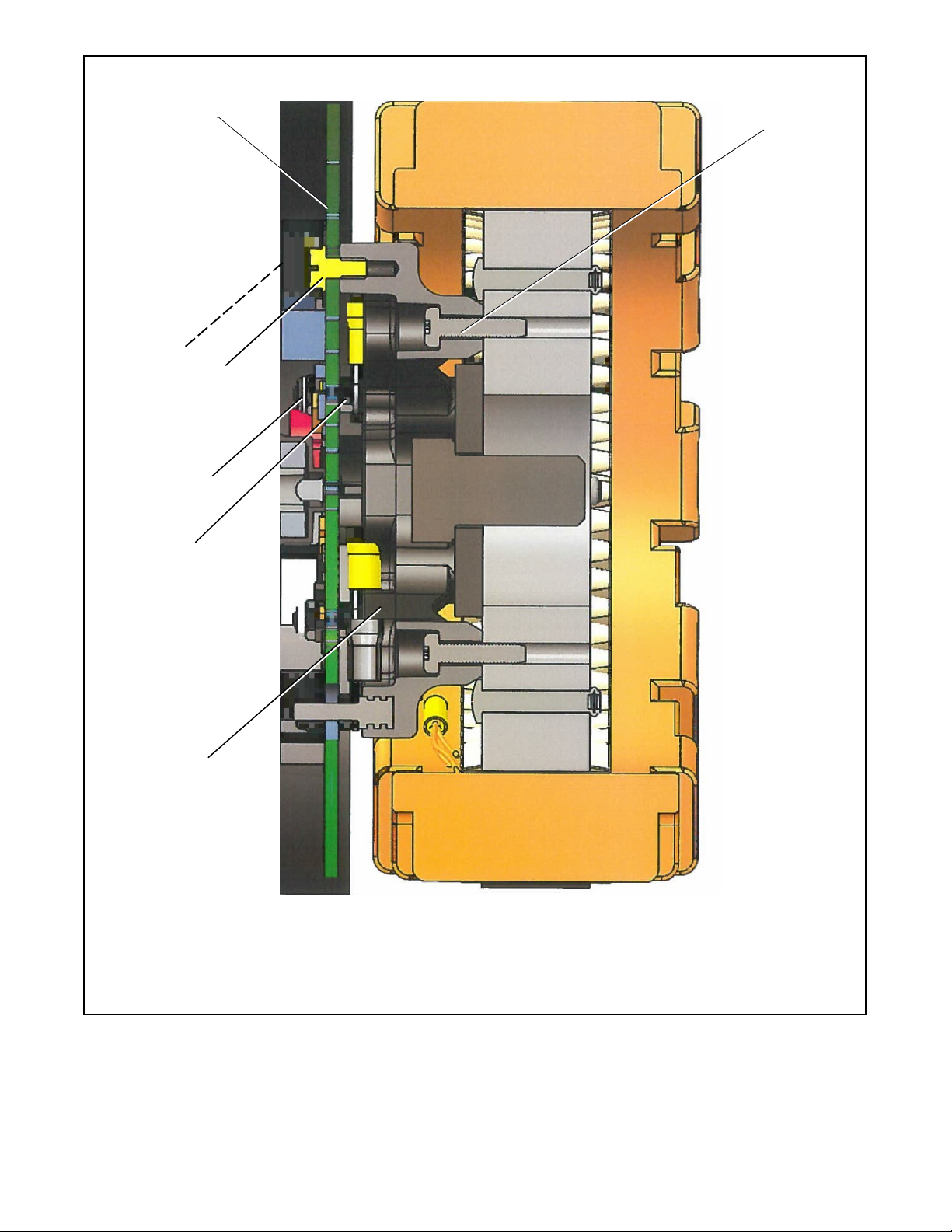

Use the FRX activator service kit when replacing the

FRX activator board on 20--200 kW generator sets that

are equipped with a Fast-ResponserX alternator.

Read the entire installation procedure and compare the

kit parts with the parts list at the end of this publication

before beginning installation. Perform the steps in the

order shown.

Safety Precautions

Observe the following safety precautions while

performing this procedure.

Accidental starting.

Can cause severe injury or death.

Disconnect the battery cables before

working on the generator set.

Remove the negative (--) lead first

when disconnecting the battery.

Reconnect the negative (--) lead last

when reconnecting the battery.

WARNING

Disabling the generator set. Accidental starting can

cause severe injury or death. Before working on the

generator set or equipment connected to the set, disable the

generator set as follows: (1) Move the generator set master

switch to the OFF position. (2) Disconnect the power to the

battery charger. (3) Remove the battery cables, negative (--)

lead first. Reconnect the negative (--) lead last when

reconnecting the battery. Follow these precautions to prevent

starting of the generator set by an automatic transfer switch,

remote start/stop switch, or engine start command from a

remote computer.

(Decision-Makerr3+ and 550 Controllers)

Disabling the generator set. Accidental starting can

cause severe injury or death. Before working on the

generator set or equipment connected to the set, disable the

generator set as follows: (1) Press the generator set off/reset

button to shut down the generator set. (2) Disconnect the

power to the battery charger, if equipped. (3) Remove the

battery cables, negative (--) lead first. Reconnect the negative

(--) lead last when reconnecting the battery. Follow these

precautions to prevent the starting of the generator set by the

remote start/stop switch.

(RDC, DC, RDC2, DC2, Decision-Makerr3000, 3500, and

6000 Controllers)

Procedure

Note: Read all safety precautions at the beginning of

this publication before performing any work on

the generator set.

1. Remove the generator set from service.

1.1 Press the generator set master control

OFF/RESET button or move the generator set

master switch to the OFF position.

1.2 Disconnect power to the battery charger, if

equipped.

1.3 Disconnect the generator set engine starting

battery, negative (--) lead first.

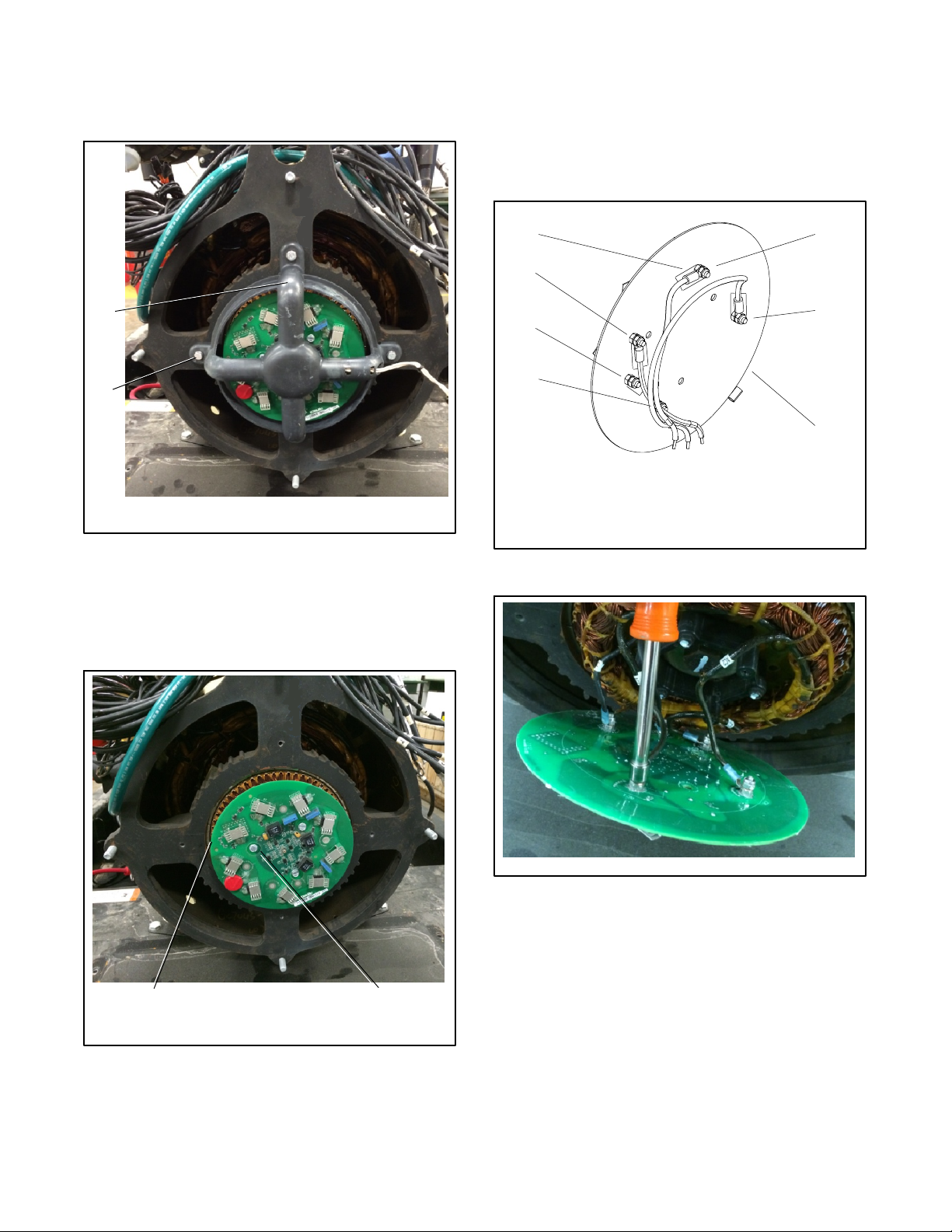

2. Access the alternator end of the

generator set.

2.1 Open the enclosure panels as needed.

2.2 Remove the junction box rear cover.

2.3 Remove the alternator (rodent) guard, if used.