5

6.Commissioning

Important:

Before commissioning the machine read this

operating manual carefully. Please also pay

attention to the pictures shown on page 10 to

16.

6.1 General

The Portiomat PM 150 is designed for the preparation of

ready-for-sale portions of minced meat products resting

upon paper mats in suitable flat containers and has its

own integrated conveyor belt for moving the product

away from the machine. It is particularly suitable for use

in the meat industry.

It is used by suppliers and supermarkets for the

processing of larger quantities of individual portions of

minced meat products. The temperature of the processed

meat is about 0 – 4 °C.

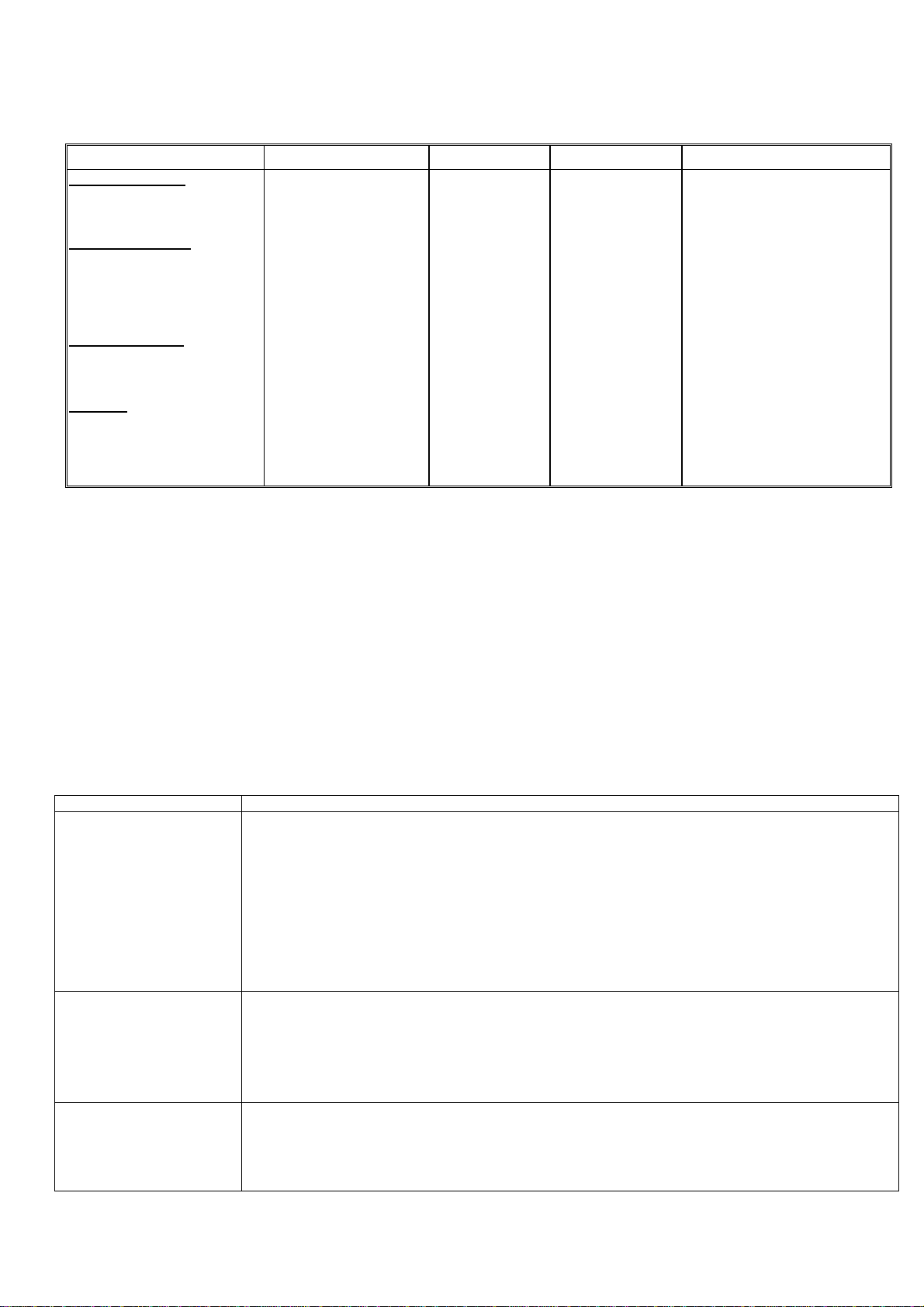

6.2 Coupling the unit to the mincer

It is absolutely essential that the mains supply to the

machine be disconnected before coupling or uncoupling

the two units (pull out the cable plug!).

Depending upon the nature of the portion of minced meat

– i.e. whether it is patty-, free-flow- or Cevapcici-form –

the appropriate processing unit on the mincer casing (5)

together with the cutting element are to be checked. In

other words, ensure that the cutting element and the

moulded sleeve (52) or the transfer unit (54) are mounted

both horizontally and parallel with one another and that

the sealing nut (50) or (53) is properly tightened. After

this, using the two operating handles (42 and 46) open

the protection plates (43 and 45) of the front inspection

door (28). Slide up the equipment and couple it to the

moulded sleeve (52) or the free-flow transfer unit (54) as

appropriate. If necessary, match the height levels by

means of the height-adjustment screw or the winding

handle (48).

6.3 Current-operated safety interlocks

The Portiomat PM 150 will only operate if the safety cover

(7), the inspection door (28) and the side-door (25) are

closed. The power supply is turned on and off by a rotary

switch (17). The activating magnets (8 and 27) and the

internally-located sensors of the safety cover (7) together

with the inspection door (28) or the side-door (25) provide

an interlocking safety function so that the current is cut off

if any of them are opened.

6.4 Procedure for changing rolls of paper

- Disconnect the main power supply (pull out the plug!)

- Open both strap clips (29)

- Open the inspection door

- Remove the star grip screw (31) and withdraw the

articulated crank axle (33) from the winding handle

eccentric (32)

- Open the spring lock on conveyor belt (34) and swivel out

the moving knife frame (24) complete with the roller then

between the moulded sleeve (52) or the free-flow transfer

unit (54) and the moving knife frame (24), see page 11.

6.5 Removing the moving knife

- Disconnect the main power supply (pull out the plug!)

- Open both strap clips (29)

- Open the inspection door

- Remove the star grip screw (31) and withdraw the

articulated crank axle (33) from the winding handle

eccentric (32)

- Open the spring lock of conveyor belt (34) and swivel

out the moving knife frame (24) complete with the

moving knife (35) ensuring that in so doing the moving

knife is held in position

- Finally withdraw the moving knife (35) in a downwards

direction

- Remove the moving knife frame (24) including the knife-

guidance frames (40 and 41) from the two hinges in an

upwards direction

- Replacement of the knife takes place in the reverse

order of sequence as described above

6.6 Adjustment of inclination the delivery conveyor belt

- Disconnect the main power supply (pull out the plug!)

- Open the safety cover (7)

- It is possible vary the angle of inclination of the paper roll

shaft (19) between roughly 0 and 10° by loosening the

butterfly-nut (49)

- After this, the angle of the discharge belt (9) is fixed in

position by re-tightening the butterfly nut (49)

6.7 Dismantling the conveyor belt

- Disconnect the main power supply (pull out the plug!)

- Open the safety cover (7)

- A tension-control flap device (15) is located beyond the

deflection roller (16) and this should be lifted upwards to

release the tension in the conveyor belt (14)

- Remove the conveyor belt (14) sideways

- Replacement of the conveyor belt takes place in the

reverse order of sequence as described

6.8 Setting-up the portion length (portion weight)

The portion length (or the portion weight) can be adjusted in

a stepless manner by a movable reflected light probe (11).

Any necessary alteration is effected by using the length scale

and the side-mounted star grip (12). Since the nature of the

portion and the consistency of the minced meat (e.g.

depending on whether it is mixed meat, seasoned meat, etc.)

have an influence upon the weight the relationship between

length and weight is only an approximate one.

The adjustment range varies between about 80 and 300 mm

.